Трябва да сте влезли в

Category

Снимките са само с информационна цел. Вижте спецификацията на продукта

please use latin characters

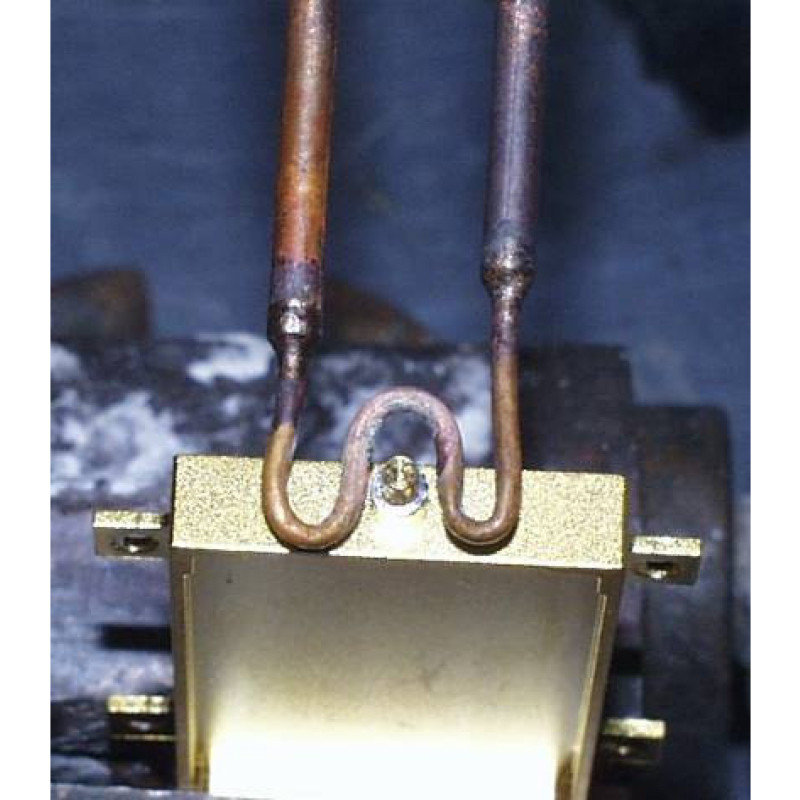

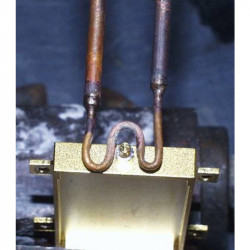

Objective: Soldering a fiber optics cable in a ferrule to form a hermetic seal.

Frequency: 346 kHz

Material: Panda PM fiber 0.0098” (.25mm) dia, kovar ferrule 0.086” (2.2mm) dia and metal enclosure 1.96” x 1.06” x 0.23” thick (50mm x 27mm x 5.9mm thick), solder preforms and flux

Temperature: 450 ºF (232 ºC)

A single turn channel “C” coil is used for this soldering application. Assembly is fluxed at the joint area and power is applied for 15 seconds to create the hermetic seal in the ferrule. The customer chose our solution due to the ability to design the single channel “C” coil. The coil heats quickly so that the heat does not travel to heat sensitive components in the case.

Интересувате ли се от този продукт? Имате ли нужда от допълнителна информация или индивидуални цени?

Трябва да сте влезли

Objective: Soldering a fiber optics cable in a ferrule to form a hermetic seal.

Frequency: 346 kHz

Material: Panda PM fiber 0.0098” (.25mm) dia, kovar ferrule 0.086” (2.2mm) dia and metal enclosure 1.96” x 1.06” x 0.23” thick (50mm x 27mm x 5.9mm thick), solder preforms and flux

Temperature: 450 ºF (232 ºC)

A single turn channel “C” coil is used for this soldering application. Assembly is fluxed at the joint area and power is applied for 15 seconds to create the hermetic seal in the ferrule. The customer chose our solution due to the ability to design the single channel “C” coil. The coil heats quickly so that the heat does not travel to heat sensitive components in the case.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Напишете свой отзив

Review sent

Your review cannot be sent