Трябва да сте влезли в

Category

Снимките са само с информационна цел. Вижте спецификацията на продукта

please use latin characters

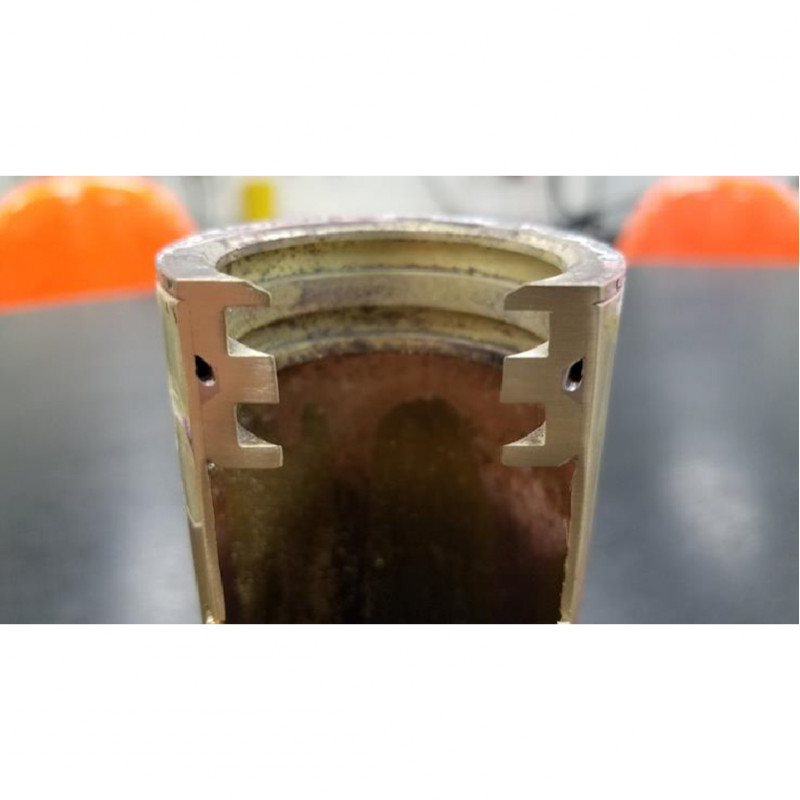

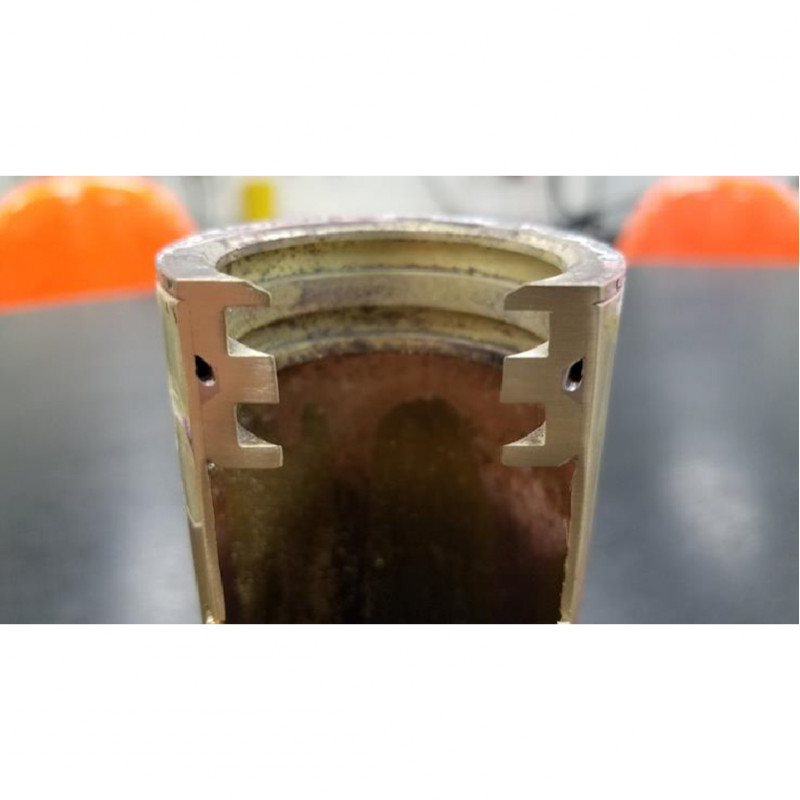

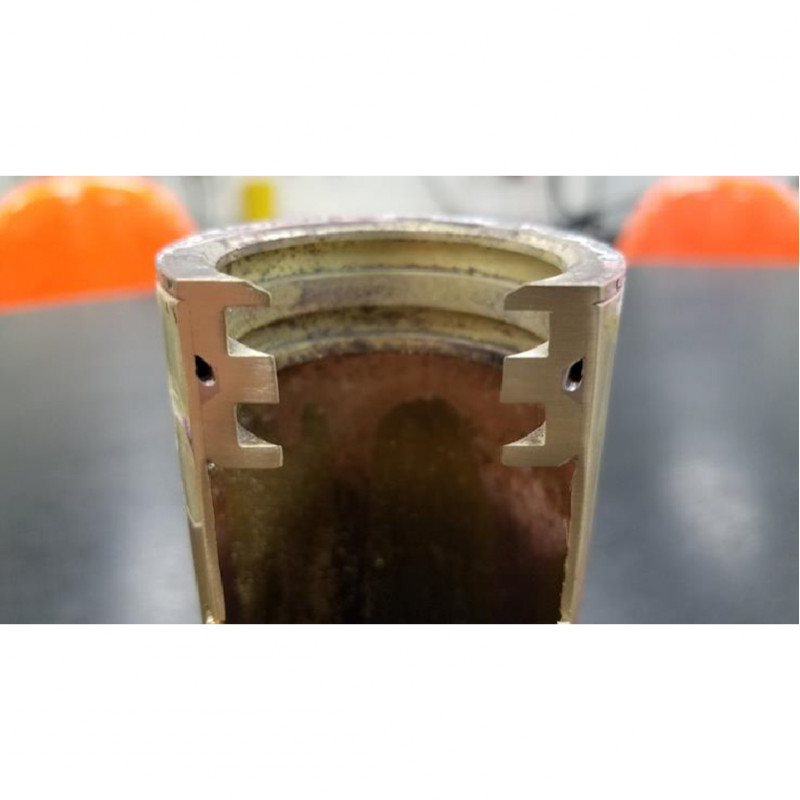

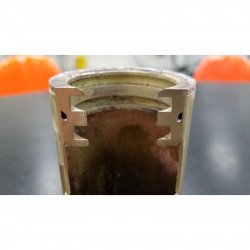

Objective: To heat brass assemblies for a brazing application; the client had been using a torch and is a manufacturer of sink products.

Frequency: 316 kHz

Material: Brass assemblies (2”/51 mm OD)

Temperature: 1425 °F (773 °C)

A custom-designed single position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. It took two minutes to heat the 2”/51 mm OD brass assembly to temperature.

Интересувате ли се от този продукт? Имате ли нужда от допълнителна информация или индивидуални цени?

Трябва да сте влезли

Objective: To heat brass assemblies for a brazing application; the client had been using a torch and is a manufacturer of sink products.

Frequency: 316 kHz

Material: Brass assemblies (2”/51 mm OD)

Temperature: 1425 °F (773 °C)

A custom-designed single position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. It took two minutes to heat the 2”/51 mm OD brass assembly to temperature.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Напишете свой отзив

Review sent

Your review cannot be sent