Трябва да сте влезли в

Category

Снимките са само с информационна цел. Вижте спецификацията на продукта

please use latin characters

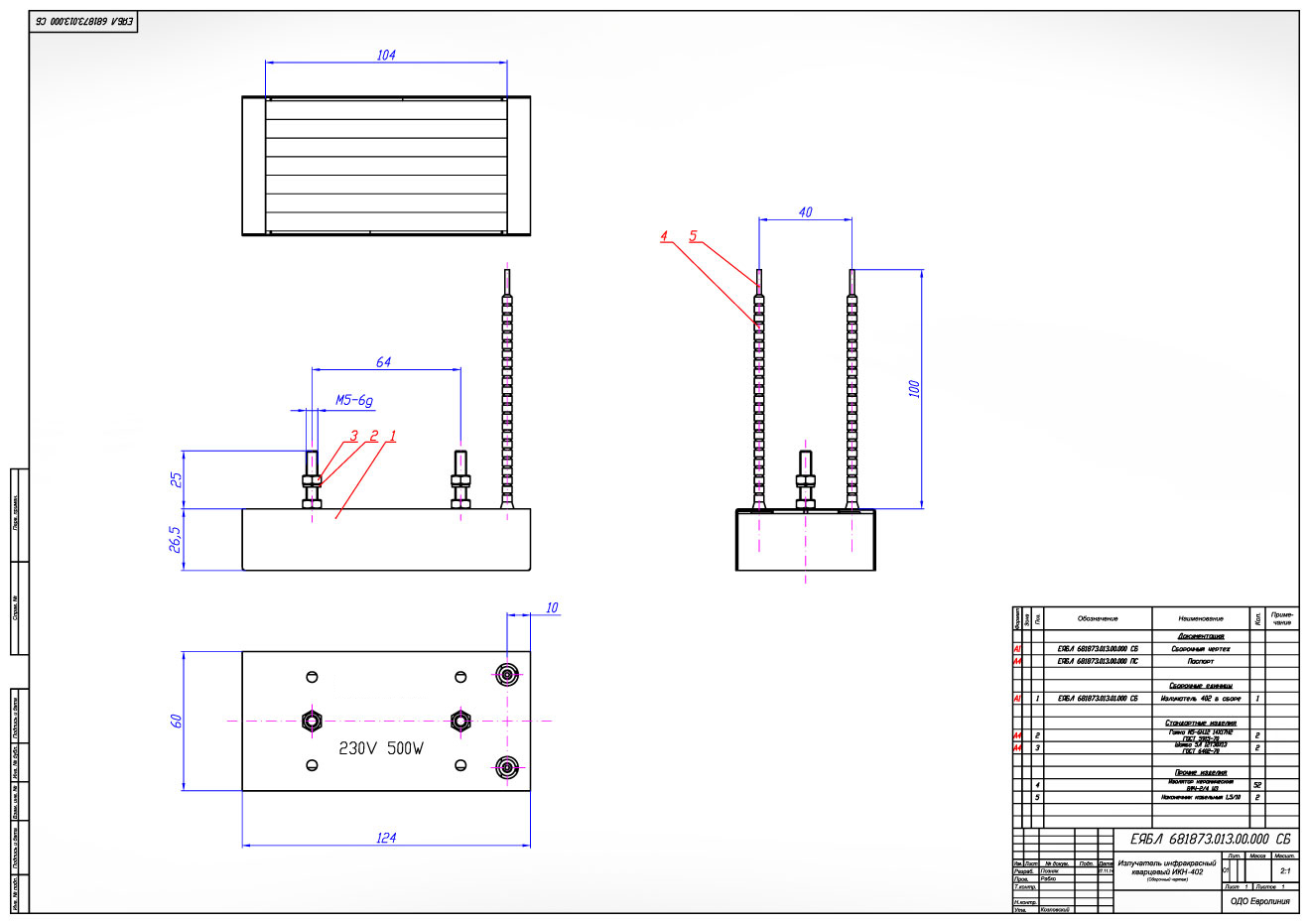

ICH-402 Half Quartz Infrared Heating Elements (HQE) is a cassette-style block of 7 half-length (104mm/~4inch) energy-efficient IR quartz emitters secured in a heat resistant stainless steel housing.

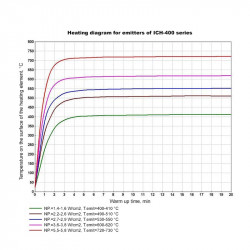

It is an instantly responding and a very efficient source of radiant heat. It can heat up in just 1-3 minutes and cool off in about 20 seconds. These emitters are essential tools for the processes that need an immediate heat-up and cool down, where the product could be damaged because of a heater remaining too hot after the power is cut off.

| Electric Power | 125W | 200W | 250W | 325W | 500W |

|---|---|---|---|---|---|

| Power density, W/m² | 16 | 26 | 32 | 41 | 64 |

| Maximum surface temperature1), °C / °F | 410/770 | 520/968 | 570/1058 | 630/1168 | 740/1364 |

| Specific surface radiation energy1), W/cm² | 1,05 | 1,91 | 2,43 | 3,21 | 5,06 |

| Useful wavelength, µm | 2,15-10,3 | 1,85-8,9 | 1,75-8,4 | 1,65-7,8 | 1,45-7,0 |

| Maximum spectral radiation intensity wavelength, µm | 4,2 | 3,7 | 3,4 | 3,2 | 2,9 |

| Time needed to reach the operating temperature1), min | 3 | 3 | 3 | 2 | 1 |

| Emitter maximum temperature, °C / °F | 780/1436 | ||||

| AC power supply (50 Hz), V | 220/230 | ||||

| Operation mode | Long term, under supervision | ||||

| Case, emitter dimensions (length x width, mm/inch) | 124х60, 104х59 / 4.88x2.36, 4.09x2.32 | ||||

| Effective emitter surface, mm² / in² | 784/1.21 | ||||

| Weight, g / oz | 210/7.40 | ||||

1) reached at ambient temperature from +18 to +25°C

ICH-400 series infrared quartz heaters are used for industrial and commercial heating systems. An instant heat response is required: thermoforming, drying chambers, infrared tunnels and panels, heating and drying conveyors, and program alternating power infrared soldering stations.

Интересувате ли се от този продукт? Имате ли нужда от допълнителна информация или индивидуални цени?

Трябва да сте влезли

ICH-402 Half Quartz Infrared Heating Elements (HQE) is a cassette-style block of 7 half-length (104mm/~4inch) energy-efficient IR quartz emitters secured in a heat resistant stainless steel housing.

It is an instantly responding and a very efficient source of radiant heat. It can heat up in just 1-3 minutes and cool off in about 20 seconds. These emitters are essential tools for the processes that need an immediate heat-up and cool down, where the product could be damaged because of a heater remaining too hot after the power is cut off.

| Electric Power | 125W | 200W | 250W | 325W | 500W |

|---|---|---|---|---|---|

| Power density, W/m² | 16 | 26 | 32 | 41 | 64 |

| Maximum surface temperature1), °C / °F | 410/770 | 520/968 | 570/1058 | 630/1168 | 740/1364 |

| Specific surface radiation energy1), W/cm² | 1,05 | 1,91 | 2,43 | 3,21 | 5,06 |

| Useful wavelength, µm | 2,15-10,3 | 1,85-8,9 | 1,75-8,4 | 1,65-7,8 | 1,45-7,0 |

| Maximum spectral radiation intensity wavelength, µm | 4,2 | 3,7 | 3,4 | 3,2 | 2,9 |

| Time needed to reach the operating temperature1), min | 3 | 3 | 3 | 2 | 1 |

| Emitter maximum temperature, °C / °F | 780/1436 | ||||

| AC power supply (50 Hz), V | 220/230 | ||||

| Operation mode | Long term, under supervision | ||||

| Case, emitter dimensions (length x width, mm/inch) | 124х60, 104х59 / 4.88x2.36, 4.09x2.32 | ||||

| Effective emitter surface, mm² / in² | 784/1.21 | ||||

| Weight, g / oz | 210/7.40 | ||||

1) reached at ambient temperature from +18 to +25°C

ICH-400 series infrared quartz heaters are used for industrial and commercial heating systems. An instant heat response is required: thermoforming, drying chambers, infrared tunnels and panels, heating and drying conveyors, and program alternating power infrared soldering stations.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Напишете свой отзив

Review sent

Your review cannot be sent