Трябва да сте влезли в

Category

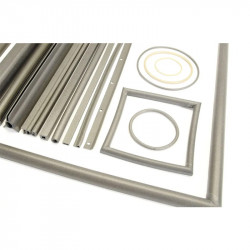

Снимките са само с информационна цел. Вижте спецификацията на продукта

please use latin characters

A comprehensive range of cross sections and materials are available in extruded form. The profiles shown below are preferred standard sizes that are readily available. T. C. Shielding also manufacture many customer specials for applications that are not satisfied by standard profiles. Typical cross sectional tolerance: +0.15mm. All dimensions shown in mm.

| EcE Material Reference (Type) | 1A/1 | IB/1 | IB/2 | ID/1 | 11/1 | 11/3 | 11/4 |

|---|---|---|---|---|---|---|---|

| Elastomer Type (Sil - Silicone, F/Sil - Fluorosilicone) | Sil | Sil | Sil | Sil | Sil | Si 1 | Sil |

| Filler Material (Silver on Aluminium,Nickel,Copper,Glass [&] Nickel Graphite) | Ag/Ni | Ag/Cu | Ag/Cu | Ag/Al | Ag/Glass | Ag/Glass | Ag/Glass |

| Colour | Tan | Tan | Tan | Tan | Tan | Tan | Tan |

| EcE Material Reference (Type) | 1J/2 | 1J/3 | ID/2 | 2A | 2B | 2D | 2J |

|---|---|---|---|---|---|---|---|

| Elastomer Type (Sil - Silicone, F/Sil - Fluorosilicone) | Sil | Sil | Sil | F/Sil | F/Sil | F/Sil | F/Sil |

| Filler Material (Silver on Aluminium,Nickel,Copper,Glass [&] Nickel Graphite) | Ni/Gr | Ni/Gr | Ag/Al | Ag/Ni | Ag/Cu | Ag/Al | Ni/Gr |

| Colour | Grey | Grey | Tan | Tan | Tan | Lt Grn | Dk Grn |

| TC Ref. | Dia. a | TC Ref. | Dia. a | TC Ref. | Dia. a |

|---|---|---|---|---|---|

| 010 | 1,02 | 016 | 2,62 | 022 | 3,81 |

| 011 | 1,35 | 017 | 2,84 | 023 | 4,06 |

| 012 | 1,57 | 018 | 3,02 | 024 | 4,78 |

| 013 | 1,78 | 019 | 3,18 | 025 | 5,49 |

| 014 | 2,03 | 020 | 3,30 | 026 | 6,35 |

| 015 | 2,36 | 021 | 3,53 |

| TC Ref. | Dia. a | Dia. b |

|---|---|---|

| 027 | 2,40 | 0,80 |

| 028 | 3,18 | 1,14 |

| 029 | 3,96 | 1,27 |

| 030 | 6,35 | 3,18 |

| 031 | 7,92 | 4,88 |

| 032 | 9,53 | 6,35 |

| TC Ref. | Dia. a | Dia. b | Rad. R |

|---|---|---|---|

| 033 | 1,40 | 1,63 | 0,70 |

| 034 | 1,57 | 1,73 | 0,79 |

| 035 | 2,39 | 1,98 | 1,19 |

| 036 | 1,98 | 2,26 | 0,99 |

| 037 | 1,57 | 2,54 | 0,79 |

| 038 | 3,81 | 2,79 | 1,91 |

| 039 | 3,00 | 3,96 | 1,50 |

| 040 | 4,52 | 4,45 | 2,26 |

| 041 | 3,96 | 3,96 | 1,98 |

| TC Ref. | Dia. a | Dia. b | Dia. c | Rad. R |

|---|---|---|---|---|

| 042 | 3,96 | 3,96 | 1,14 | 1,98 |

| 043 | 4,75 | 4,72 | 1,27 | 2,36 |

| 044 | 7,92 | 7,92 | 1,27 | 3,96 |

| 045 | 7,92 | 7,92 | 1,57 | 3,96 |

| 046 | 12,37 | 8,23 | 2,03 | 6,20 |

| 047 | 6,35 | 6,35 | 1,65 | 3,18 |

| TC Ref. | Dia. a | Dia. b | TC Ref. | Dia. a | Dia. b |

|---|---|---|---|---|---|

| 048 | 1,60 | 1,07 | 067 | 12,70 | 1,91 |

| 049 | 2,41 | 1,57 | 068 | 12,70 | 3,18 |

| 050 | 3,05 | 1,91 | 069 | 12,70 | 4,78 |

| 051 | 3,18 | 1,57 | 070 | 19,05 | 1,57 |

| 052 | 3,96 | 1,57 | 071 | 22,35 | 1,57 |

| 053 | 6,35 | 1,57 | 072 | 25,40 | 6,35 |

| TC Ref. | Dia. a | Dia. b | Dia. c | Dia. d |

|---|---|---|---|---|

| 054 | 2,54 | 2,54 | 0,86 | 0,84 |

| 055 | 3,20 | 2,79 | 0,66 | 1,27 |

| 056 | 3,20 | 5,72 | 0,51 | 1,91 |

| 057 | 3,96 | 3,94 | 1,57 | 1,19 |

| 058 | 4,45 | 3,96 | 1,19 | 1,91 |

| 059 | 8,31 | 5,94 | 1,57 | 2,92 |

| TC Ref. | Dia. a | Dia. b | Dia. c | Dia. d |

|---|---|---|---|---|

| 060 | 5,08 | 2,03 | 1,57 | 12,70 |

| 061 | 5,08 | 2,03 | 1,57 | 21,59 |

| 062 | 6,35 | 3,18 | 1,57 | 12,70 |

| 063 | 6,35 | 3,18 | 1,57 | 15,88 |

| 064 | 6,35 | 3,18 | 1,57 | 22,22 |

| 065 | 7,92 | 4,75 | 1,57 | 22,22 |

| 066 | 9,14 | 6,48 | 1,79 | 19,81 |

| TC Ref. | Dia.a | Dia.b | Dia.c |

|---|---|---|---|

| 073 | 7,75 | 8,38 | 3,18 |

| 074 | 9,53 | 9,53 | 4,78 |

Przykład zamówienia EA-XX-XXX

Przykład: EA - 1D/1 - 010

EA - wytłaczane

1D/1 - opiłki srebra

010 - Dia.ar 1,02 mm, profil 'O'

Uwaga: inne kształty dostępne na zapytanie.

Special Extruded Profiles

Non standard profiles that have all been developed to suit specific customer applications for carbon loadedelastomer seals.

Based on carbon loaded silicone, a range of clip-on, rivet mounted and P.S.A. backed extrusions can be supplied as extruded lengths or mitre jointed to suit cabinets,

Uwaga:

Możliwość zaprojektowania i wykonania profilu pod Dia.gania klienta.

W celu uzyskania szczegółowych informacji prosimy o kontakt z działem technicznym DACPOL Sp. z o.o.

Интересувате ли се от този продукт? Имате ли нужда от допълнителна информация или индивидуални цени?

Трябва да сте влезли

A comprehensive range of cross sections and materials are available in extruded form. The profiles shown below are preferred standard sizes that are readily available. T. C. Shielding also manufacture many customer specials for applications that are not satisfied by standard profiles. Typical cross sectional tolerance: +0.15mm. All dimensions shown in mm.

| EcE Material Reference (Type) | 1A/1 | IB/1 | IB/2 | ID/1 | 11/1 | 11/3 | 11/4 |

|---|---|---|---|---|---|---|---|

| Elastomer Type (Sil - Silicone, F/Sil - Fluorosilicone) | Sil | Sil | Sil | Sil | Sil | Si 1 | Sil |

| Filler Material (Silver on Aluminium,Nickel,Copper,Glass [&] Nickel Graphite) | Ag/Ni | Ag/Cu | Ag/Cu | Ag/Al | Ag/Glass | Ag/Glass | Ag/Glass |

| Colour | Tan | Tan | Tan | Tan | Tan | Tan | Tan |

| EcE Material Reference (Type) | 1J/2 | 1J/3 | ID/2 | 2A | 2B | 2D | 2J |

|---|---|---|---|---|---|---|---|

| Elastomer Type (Sil - Silicone, F/Sil - Fluorosilicone) | Sil | Sil | Sil | F/Sil | F/Sil | F/Sil | F/Sil |

| Filler Material (Silver on Aluminium,Nickel,Copper,Glass [&] Nickel Graphite) | Ni/Gr | Ni/Gr | Ag/Al | Ag/Ni | Ag/Cu | Ag/Al | Ni/Gr |

| Colour | Grey | Grey | Tan | Tan | Tan | Lt Grn | Dk Grn |

| TC Ref. | Dia. a | TC Ref. | Dia. a | TC Ref. | Dia. a |

|---|---|---|---|---|---|

| 010 | 1,02 | 016 | 2,62 | 022 | 3,81 |

| 011 | 1,35 | 017 | 2,84 | 023 | 4,06 |

| 012 | 1,57 | 018 | 3,02 | 024 | 4,78 |

| 013 | 1,78 | 019 | 3,18 | 025 | 5,49 |

| 014 | 2,03 | 020 | 3,30 | 026 | 6,35 |

| 015 | 2,36 | 021 | 3,53 |

| TC Ref. | Dia. a | Dia. b |

|---|---|---|

| 027 | 2,40 | 0,80 |

| 028 | 3,18 | 1,14 |

| 029 | 3,96 | 1,27 |

| 030 | 6,35 | 3,18 |

| 031 | 7,92 | 4,88 |

| 032 | 9,53 | 6,35 |

| TC Ref. | Dia. a | Dia. b | Rad. R |

|---|---|---|---|

| 033 | 1,40 | 1,63 | 0,70 |

| 034 | 1,57 | 1,73 | 0,79 |

| 035 | 2,39 | 1,98 | 1,19 |

| 036 | 1,98 | 2,26 | 0,99 |

| 037 | 1,57 | 2,54 | 0,79 |

| 038 | 3,81 | 2,79 | 1,91 |

| 039 | 3,00 | 3,96 | 1,50 |

| 040 | 4,52 | 4,45 | 2,26 |

| 041 | 3,96 | 3,96 | 1,98 |

| TC Ref. | Dia. a | Dia. b | Dia. c | Rad. R |

|---|---|---|---|---|

| 042 | 3,96 | 3,96 | 1,14 | 1,98 |

| 043 | 4,75 | 4,72 | 1,27 | 2,36 |

| 044 | 7,92 | 7,92 | 1,27 | 3,96 |

| 045 | 7,92 | 7,92 | 1,57 | 3,96 |

| 046 | 12,37 | 8,23 | 2,03 | 6,20 |

| 047 | 6,35 | 6,35 | 1,65 | 3,18 |

| TC Ref. | Dia. a | Dia. b | TC Ref. | Dia. a | Dia. b |

|---|---|---|---|---|---|

| 048 | 1,60 | 1,07 | 067 | 12,70 | 1,91 |

| 049 | 2,41 | 1,57 | 068 | 12,70 | 3,18 |

| 050 | 3,05 | 1,91 | 069 | 12,70 | 4,78 |

| 051 | 3,18 | 1,57 | 070 | 19,05 | 1,57 |

| 052 | 3,96 | 1,57 | 071 | 22,35 | 1,57 |

| 053 | 6,35 | 1,57 | 072 | 25,40 | 6,35 |

| TC Ref. | Dia. a | Dia. b | Dia. c | Dia. d |

|---|---|---|---|---|

| 054 | 2,54 | 2,54 | 0,86 | 0,84 |

| 055 | 3,20 | 2,79 | 0,66 | 1,27 |

| 056 | 3,20 | 5,72 | 0,51 | 1,91 |

| 057 | 3,96 | 3,94 | 1,57 | 1,19 |

| 058 | 4,45 | 3,96 | 1,19 | 1,91 |

| 059 | 8,31 | 5,94 | 1,57 | 2,92 |

| TC Ref. | Dia. a | Dia. b | Dia. c | Dia. d |

|---|---|---|---|---|

| 060 | 5,08 | 2,03 | 1,57 | 12,70 |

| 061 | 5,08 | 2,03 | 1,57 | 21,59 |

| 062 | 6,35 | 3,18 | 1,57 | 12,70 |

| 063 | 6,35 | 3,18 | 1,57 | 15,88 |

| 064 | 6,35 | 3,18 | 1,57 | 22,22 |

| 065 | 7,92 | 4,75 | 1,57 | 22,22 |

| 066 | 9,14 | 6,48 | 1,79 | 19,81 |

| TC Ref. | Dia.a | Dia.b | Dia.c |

|---|---|---|---|

| 073 | 7,75 | 8,38 | 3,18 |

| 074 | 9,53 | 9,53 | 4,78 |

Przykład zamówienia EA-XX-XXX

Przykład: EA - 1D/1 - 010

EA - wytłaczane

1D/1 - opiłki srebra

010 - Dia.ar 1,02 mm, profil 'O'

Uwaga: inne kształty dostępne na zapytanie.

Special Extruded Profiles

Non standard profiles that have all been developed to suit specific customer applications for carbon loadedelastomer seals.

Based on carbon loaded silicone, a range of clip-on, rivet mounted and P.S.A. backed extrusions can be supplied as extruded lengths or mitre jointed to suit cabinets,

Uwaga:

Możliwość zaprojektowania i wykonania profilu pod Dia.gania klienta.

W celu uzyskania szczegółowych informacji prosimy o kontakt z działem technicznym DACPOL Sp. z o.o.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Напишете свой отзив

Review sent

Your review cannot be sent