Трябва да сте влезли в

Category

Снимките са само с информационна цел. Вижте спецификацията на продукта

please use latin characters

To keep up with the growing market for television picture tubes, manufacturers are constantly searching for faster, more cost-effective production techniques.

One such method is to insert or "seal" metal anchoring pins to the TV picture tube glass panels. The pins, which may be solid or hollow in design, aid in the assembly process by providing a mounting support for the phosphor shadow mask and cathode ray tube.

Temperature requirements for pin sealing are stringent due to the delicate nature of glass and the importance of a quality insertion.

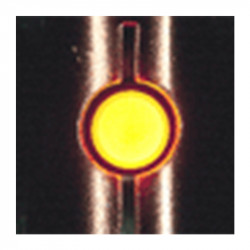

Modern induction heating systems have the precision and speed required to make television picture glass pin sealing a production process. One or more pins are typically heated to approximately 1100°C for insertion into the glass panel. At the time of insertion, the glass panel is still at what is known as the softening point (400°C). Glass at the softening point has a viscosity equal to or less than 4x106 Pa-s, allowing the panel to be handled without causing significant dimensional alterations. Typical frequencies for pin sealing are 200 to 700 kHz, depending on how many pins are being heated

Typical induction systems typically used for pin sealing range from 3 to 20 kW, depending on the parts and application requirements.

Интересувате ли се от този продукт? Имате ли нужда от допълнителна информация или индивидуални цени?

Трябва да сте влезли

To keep up with the growing market for television picture tubes, manufacturers are constantly searching for faster, more cost-effective production techniques.

One such method is to insert or "seal" metal anchoring pins to the TV picture tube glass panels. The pins, which may be solid or hollow in design, aid in the assembly process by providing a mounting support for the phosphor shadow mask and cathode ray tube.

Temperature requirements for pin sealing are stringent due to the delicate nature of glass and the importance of a quality insertion.

Modern induction heating systems have the precision and speed required to make television picture glass pin sealing a production process. One or more pins are typically heated to approximately 1100°C for insertion into the glass panel. At the time of insertion, the glass panel is still at what is known as the softening point (400°C). Glass at the softening point has a viscosity equal to or less than 4x106 Pa-s, allowing the panel to be handled without causing significant dimensional alterations. Typical frequencies for pin sealing are 200 to 700 kHz, depending on how many pins are being heated

Typical induction systems typically used for pin sealing range from 3 to 20 kW, depending on the parts and application requirements.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Напишете свой отзив

Review sent

Your review cannot be sent