Трябва да сте влезли в

Как да изберем LED осветление? Ръководство за издръжливост, тестване и заместители

LED осветление (светодиод) е съвременна технология, която революционизира начина, по който се осветяват както домашни, така и индустриални пространства. Светодиодите LED са известни със своята енергийна ефективност, дълъг живот и висока светлинна продукция. Благодарение на тези характеристики, LED осветлението се е утвърдило като не само екологично решение, но и икономично такова.

В индустрията, където оперативните разходи и надеждността са от решаващо значение, LED технологията се доказва като идеална. Необходимостта от устойчивост на тежки условия на работа като висока влажност, присъствие на масла или вибрации я прави отличен избор за приложения в CNC машини, производствени линии и други изискващи среди. Освен това, отсъствието на UV и IR радиация гарантира, че LED светодиодите не затоплят повърхностите, които осветяват, което е от съществено значение в прецизните производствени процеси.

Как се тества LED осветлението?

Как се тества дълготрайността на LED?

Тестването на дълготрайността на LED е съществена част от проверката на качеството и надеждността на продуктите. Поради дългия живот, деклариран от производителите, който може да бъде до 50 000 часа, стандартните методи за тестване трябва да бъдат съответно адаптирани. Продължителните тестове биха отнели повече от 5,7 години, така че са разработени по-ефективни и съкратени изследователски процедури.

Burn-in и стабилизация (първа фаза – 1000 часа)

Първата фаза на тестването е burn-in и стабилизация на LED-ите, което трае 1000 часа. По време на този период осветлението работи при контролирани условия с подходящо подаване на ток или напрежение. Целта на тази фаза е да се оцени началното увеличение на светлинната продукция, което често се случва през първите часове на използване. Стабилизирането на параметрите на LED след този период позволява получаването на по-надеждни резултати при следващите тестове.

Дълготрайни тестове (втора фаза – 5000-6000 часа)

Втората фаза включва тестове, които траят от 5000 до 6000 часа. След този период се извършва измерване на светлинната продукция, което се сравнява с получената стойност в първата фаза. Резултатите помагат за оценка дали спадът в яркостта надвишава 30% от началната стойност. Ако спадът на светлинната продукция остане в рамките на посочените граници, анализът може да премине към следващата стъпка.

Екстраполация на резултатите – как се предсказва дълготрайността на LED въз основа на тестовете?

На базата на данните, получени по време на тестовете, се извършва екстраполация, която позволява да се предскаже дългосрочната дълготрайност на LED. Ако след 6000 часа светлинната продукция не е спаднала под 70% от началната стойност, LED-ите отговарят на изискванията за дълъг живот. Този метод позволява надеждна оценка на дълготрайността без необходимост от многогодишни тестове.

Съвременни методи за определяне на дълготрайността на LED (според стандартите на IEC)

Стандартите на IEC въвеждат методи за определяне на дълготрайността на LED, които включват измервания при различни температури и оценка на качеството на LED модула. Тези тестове са по-точни и отразяват реалните условия, при които се използва осветлението.

Измерване при различни температури (55°C, 85°C и температура на производителя)

Според стандартите на IEC, дълготрайността на LED се оценява на базата на измервания на светлинната продукция, извършени при три температури: 55°C, 85°C и температурата, посочена от производителя. Основен елемент е наблюдението на температурата в точката на измерване на LED модула, което позволява точно определяне на това как термичните условия влияят на дълготрайността на LED.

Проверка на спад в светлинната продукция (70% като минимален праг)

По време на тестовете се проверява дали спадът в светлинната продукция по време на употреба не надвишава 30% от началната стойност. Ако светлинната продукция остава над 70% от началната яркост, дълготрайността на LED се счита за отговаряща на декларациите на производителя. Този подход предоставя по-добра проверка на качеството на осветлението и помага за приспособяване на продуктите за изискващи индустриални приложения.

Какви фактори влияят на дълготрайността на LED осветлението?

Влияние на температурата върху живота на LED

Оперативната температура е един от най-важните фактори, които влияят на дълготрайността и производителността на LED. Високите температури, особено при съединението на полупроводника, могат да ускорят процеса на стареене на компонентите и да доведат до по-бързо намаляване на светлинната продукция. За да се предотврати това, производителите използват усъвършенствани решения за разсейване на топлина.

Защо температурата на съединението на полупроводника е критична?

Съединението на полупроводника, където се генерира светлината, е особено чувствително към прегряване. Повишените температури могат да доведат до деградация на материалите, използвани в LED, и да намалят ефективността на емисията на светлина. Поддържането на подходяща температура на съединението е от съществено значение за осигуряване на обявената дълготрайност на диодите.

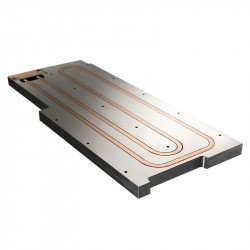

Какви решения за разсейване на топлината осигуряват дълготрайност?

За ефективно разсейване на топлината производителите използват различни технологии, като:

• Алуминеви радиатори – те увеличават повърхността за топлинен обмен и позволяват бързо отстраняване на топлината от LED модулите.

• Термични пасти – те подобряват топлинната проводимост между LED модула и радиатора.

• Активни охлаждащи системи – в по-изискващи приложения се използват вентилатори или други механични решения за осигуряване на ефективно охлаждане.

Ролята на правилното захранване

Качеството на захранването е също толкова важно за дълготрайността на LED осветлението. Флуктуации на напрежението, пренапрежения или хармонични смущения могат да повлияят на работата на диодите, водейки до повреди или намалена ефективност.

Влияние на нарушенията в мрежата върху дълготрайността на LED

Електрическите мрежови нарушения, като хармоници, миготене или пренапрежения, могат да окажат негативно въздействие върху живота на LED осветлението. Например:

• Миготене (миготене на светлината) – може да предизвика нестабилност на захранването и да ускори деградацията.

• Пренапрежения – кратки напреженови пикове могат да повредят диодите и електронните компоненти в LED драйверите.

Как хармониците, миготенето и пренапреженията могат да повредят LED?

Хармониците, генерирани от мрежови нарушения, увеличават натоварването на захранващите системи. Ако LED драйверът няма подходяща защита, може да се получи постоянно увреждане на диодите. Ето защо е от съществено значение да се използват висококачествени драйвери, оборудвани с филтри за потискане на интерференцията.

Важността на съвместимите компоненти

Изборът на правилните компоненти, като радиатори, термични пасти и вентилатори, е ключов за осигуряване на дълготрайността на LED осветлението. Съвместимостта с препоръките на производителя позволява оптималната работа на цялата система.

Радиатори, термични пасти и вентилатори

Всеки от тези компоненти играе решаваща роля в системата за разсейване на топлина:

• Радиатори повишават ефективността на охлаждането.

• Термични пасти елиминират въздушните пропуски между компонентите, осигурявайки по-добър топлинен трансфер.

• Вентилатори се използват в приложения, изискващи активно охлаждане.

Защо изборът на компоненти, съвместими с препоръките на производителя, е важен?

Производителят на LED уточнява условията на работа, като максимална температура на съединението или допустими напрежения. Несъвместимостта на компонентите може да доведе до неефективно охлаждане или повреда на диодите, което значително намалява тяхната дълготрайност и ефективност.

Съвременни LED решения за индустрията

Съвременното LED осветление, проектирано за индустриална употреба, трябва да отговаря на няколко изисквания, свързани с висока енергийна ефективност, дълготрайност и устойчивост на тежки работни условия. В отговор на тези нужди, различни LED решения са налични за изискващи производствени, машинни и складови среди. Ето някои от последните продукти, които печелят популярност в индустрията:

SIRIO LED серия – Компактни и функционални осветителни тела

Серията SIRIO LED предлага разнообразие от осветителни тела, характеризирани с отлично изпълнение, компактни размери и многофункционалност. С различни опции за мощност и дължини, пригодени за различни нужди, тези осветителни тела са отличен избор за разнообразни индустриални приложения.

• SIRIO LED BLM Tube Ø70 mm – Това е едно от по-големите осветителни тела в серията, налично в няколко дължини: 505 мм, 660 мм, 10160 мм и 1465 мм. Опциите за мощност включват 24V DC, 48V DC и 230V AC, което позволява гъвкаво приспособяване към различни индустриални инсталации. В зависимост от модела, капакът е изработен от боросиликатно стъкло или метакрилат, осигурявайки устойчивост на тежки работни условия.

• SIRIO LED BLS Tube Ø60 mm – По-малка версия на осветителното тяло, предлагаща подобни параметри, но с още по-компактен дизайн. С диаметър 60 мм и различни опции за дължина, тя е идеално решение за пространства с ограничена площ за монтаж.

• SIRIO LED BLG Tube Ø50 mm – Най-малкият модел в серията, с диаметър 50 мм. Капакът е изработен от поликарбонат, което увеличава устойчивостта на механични повреди, правейки го подходящо за приложения в зони, изложени на удари и въздействия.

Машинни лампи от CCEA

Машинни лампи от CCEA са съвременни решения за изискващи индустриални среди. Продуктът разполага с здрава алуминиева кутия, която осигурява висока устойчивост на вибрации и ефективно разсейване на топлината.

• Track Alpha – Това е настенно монтирано машинно осветление, построено с устойчива алуминиева кутия, осигуряваща висока устойчивост на вибрации, масла, охлаждащи течности и прах. Track Alpha е проектиран за употреба в най-изискващите среди, като CNC машини или автоматизирани системи. С рейтинг на защита IP67, тези лампи работят отлично в влажни и прашни условия.

Лампата предлага интензивна светлинна продукция до 6500 лумена, с живот до 60 000 часа. Track Alpha е наличен в различни дължини и с различни съединители, което позволява лесен монтаж и интеграция с съществуващи осветителни системи. Освен това, лампата предлага отлична гъвкавост за монтаж и възможност за регулиране на ъгъла на светлината, което я прави изключително универсално решение за различни индустриални приложения.

Предимства на Track Alpha:

o Устойчив на масла, охлаждащи течности, мазнини и вибрации

o Дълъг експлоатационен живот – до 60 000 часа

o Спестяване на енергия – до 50% в сравнение с традиционните решения

o Лесен и бърз монтаж без необходимост от допълнителни устройства за захранване

SYMRA IP69K осветителни тела

Symra IP69K са осветителни тела с изключителна устойчивост на екстремни външни условия, което ги прави идеално решение за тежки индустриални среди, където преобладават екстремни температури, влажност или прах. Благодарение на клас защита IP69K, тези лампи са устойчиви на проникване на прах, както и на продължително потапяне във високо налягане на вода, което ги прави надеждни дори в най-изискващите условия.

SYMRA осветителни тела са проектирани с изключителна издръжливост и надеждност за предизвикателни индустриални среди. С тяхната здрава конструкция и използване на последните LED технологии, тези осветителни тела предлагат дълъг експлоатационен живот, ниска енергийна консумация и ефективно осветление. Те също така са лесни за инсталиране и поддръжка, което ги прави идеално решение за компании, търсещи надеждно осветление в тежки условия.

Предимства на SYMRA IP69K осветителни тела:

• Висока устойчивост на вода, прах и високо налягане

• Дълготрайна, енергийно ефективна работа

• Отлични светлинни характеристики и висока издръжливост

Ние също така предлагаме LED осветителни тела, проектирани за употреба в зони, където съществува потенциално експлозивна атмосфера, причинена от наличието на запалими газове или прахове. Това са лампи, които комбинират няколко метода за защита с цел намаляване на риска от искра, която да предизвика експлозия, като по този начин се поддържа нивото на безопасност на инсталацията над минимално необходимото. Всички те са ATEX сертифицирани.

Как да изберем правилното LED осветление?

Изборът на правилното LED осветление за индустриално съоръжение е от решаващо значение за осигуряване на енергийна ефективност, поддържане на дълготрайността на осветлението и подобряване на условията на работа. Важно е да се вземат предвид няколко ключови аспекта, които влияят на ефективността и надеждността на осветителните системи.

1. Дълготрайност и надеждност на LED осветлението – Първата стъпка при избора на осветление е да се проверят параметрите, свързани с дълготрайността на източниците на светлина. Тестовете на LED лампите и разбирането на факторите, които влияят на тяхната дълготрайност, като работна температура, качество на електрическото захранване или правилно управление на топлината, са основата за осигуряване на дълготрайна и ефективна работа. Важно е осветлението да бъде устойчиво на колебания в напрежението, пренапрежения и други нарушения, които могат да повлияят негативно на неговата производителност.

2. Оптимално управление на топлината – Правилното разсейване на топлината от LED диодите е един от ключовите фактори, които влияят на тяхната дълготрайност. Високите температури могат да доведат до деградация на светлинния поток и да съкратят живота на осветлението. Ето защо е добре да се изберат решения, които предлагат ефективни топлинни радиатори, термична паста или вентилатори. Изборът на компоненти, съвместими с препоръките на производителя, осигурява максимална ефективност и безопасност на системата.

3. Съвременни LED решения за индустрията – Индустриалното LED осветление не само че е енергийно ефективно, но и високо устойчиво на тежки външни условия, като влажност, прах, масла или вибрации. Продукти като Track Alpha или SYMRA IP69K осигуряват надеждност в екстремни условия. Те са устойчиви на удари, предлагат дълга издръжливост и са лесни за инсталиране и поддръжка. Ето защо е добре да се изберат продукти, които предлагат високо качество, устойчивост на външни фактори и са адаптирани към специфичните нужди на даденото съоръжение.

4. Енергийна ефективност – Спестяването на енергия е едно от основните предимства на LED технологията. Чрез избора на правилното LED осветление могат да се постигнат значителни намаления на оперативните разходи. Продукти, които предлагат дълготрайно, енергийно ефективно осветление, като серията SIRIO LED, могат да помогнат за намаляване на енергийната консумация и понижаване на разходите за осветление.

5. Адаптация към изискванията на съоръжението – Всяко индустриално съоръжение има специфични изисквания към осветлението. Ето защо е важно да се изберат осветителни тела, които най-добре отговарят на нуждите на съответната работна среда. Осветлението трябва да бъде подходящо за размера на помещенията, типа работа и техническите условия като влажност или наличие на химикали.

Резюме

Изборът на правилното LED осветление за индустриално съоръжение е инвестиция, която осигурява ползи както по отношение на спестяване на енергия, така и на ефективност. Важно е да се вземат предвид фактори като дълготрайност, устойчивост на тежки условия, енергийна ефективност и правилен монтаж. Съвременните LED решения, като тези, предлагани от компании като DACPOL, са способни да отговорят на изискванията на съвременните индустриални съоръжения, осигурявайки оптимално осветление, което подобрява безопасността и работния комфорт.

Leave a comment