Трябва да сте влезли в

-

moreX

-

Компоненти

-

-

Category

-

полупроводници

- Диоди

- Тиристори

-

Електрически изолирани модули

- Електроизолирани модули VISHAY (IR).

- Електроизолирани модули INFINEON (EUPEC).

- Електрически изолирани модули на Semikron

- Електроизолирани модули POWEREX

- Електроизолирани модули IXYS

- Електроизолирани модули от POSEICO

- Електрически изолираните модули на ABB

- Електроизолационни модули от TECHSEM

- Go to the subcategory

- Мостови токоизправители

-

Транзистори

- GeneSiC транзистори

- Mitsubishi SiC MOSFET модули

- STARPOWER SiC MOSFET модули

- ABB SiC MOSFET модули

- IGBT модули от MITSUBISHI

- Транзисторни модули MITSUBISHI

- MITSUBISHI MOSFET модули

- Транзисторни модули ABB

- IGBT модули от POWEREX

- IGBT модули - от INFINEON (EUPEC)

- Полупроводникови елементи от силициев карбид

- Go to the subcategory

- Шофьори

- Силови блокове

- Go to the subcategory

- Преобразуватели за ток и напрежение LEM

-

Пасивни компоненти (кондензатори, резистори, предпазители, филтри)

- Резистори

-

Предпазители

- Миниатюрни предпазители за електронни системи серия ABC и AGC

- Бързодействащи тръбни предпазители

- Забавени вложки с GL/GG и AM характеристики

- Изключително бързи предпазители

- Британски и американски стандартни бързодействащи предпазители

- Бързодействащи предпазители европейски стандарт

- Тягови предпазители

- Предпазители за високо напрежение

- Go to the subcategory

-

Кондензатори

- Кондензатори за двигатели

- Електролитни кондензатори

- Icel филмови кондензатори

- Силови кондензатори

- Кондензатори за постояннотокови вериги

- Кондензатори за компенсация на мощността

- Кондензатори за високо напрежение

- Кондензатори за индукционно нагряване

- Импулсни кондензатори

- DC LINK кондензатори

- Кондензатори за AC/DC вериги

- Go to the subcategory

- Филтри против смущения

- Суперкондензатори

- Защита от пренапрежение

- Разкриващи емисионни филтри TEMPEST

- Защита от пренапрежение

- Go to the subcategory

-

Релета и контактори

- Теория на релетата и контакторите

- AC 3-фазни твърдотелни релета

- DC твърдотелни релета

- Регулатори, системи за управление и аксесоари

- Мек старт и реверсивни контактори

- Електромеханични релета

- Контактори

- Ротационни превключватели

-

Еднофазни AC твърдотелни релета

- Еднофазни променливотокови полупроводникови релета Серия 1 | D2425 | D2450

- Еднофазни AC полупроводникови релета CWA и CWD серия

- Еднофазни AC полупроводникови релета серии CMRA и CMRD

- Еднофазни AC твърдотелни релета PS серия

- AC твърдотелни релета двойни и четворни серии D24 D, TD24 Q, H12D48 D

- Еднофазни полупроводникови релета от серия GN

- Еднофазни променливотокови твърдотелни релета серия CKR

- Монофазни AC релета за DIN шина ERDA и ERAA СЕРИЯ

- Монофазни AC релета за ток 150А

- Двойни твърдотелни релета, интегрирани с радиатор на DIN шина

- Go to the subcategory

- AC еднофазни печатни твърдотелни релета

- Интерфейсни релета

- Go to the subcategory

- Ядра и други индуктивни компоненти

- Радиатори, Варистори, Термична защита

- Фенове

- Климатик, Аксесоари за табла, Охладители

-

Батерии, зарядни устройства, буферни захранвания и преобразуватели

- Батерии, зарядни устройства - теоретично описание

- Литиево-йонни батерии. Персонализирани батерии. Система за управление на батерията (BMS)

- Батерии

- Зарядни за батерии и аксесоари

- UPS и буферни захранвания

- Конвертори и аксесоари за фотоволтаици

- Съхранение на енергия

- Водородни горивни клетки

- Литиево-йонни клетки

- Go to the subcategory

-

Автоматизация

- Подемници Spiralift

- Части за дронове Futaba

- Крайни изключватели, Микро ключове

- Сензори, Преобразуватели

- Пирометри

- Броячи, Релета за време, Панелни измервателни уреди

- Индустриална защитна екипировка

- Светлинни и звукови сигнали

- Термовизионна камера

- LED дисплеи

- Бутони и превключватели

- Go to the subcategory

-

Кабели, Litz проводници, Тръбопроводи, Гъвкави връзки

- Проводници

- Кабелни щуцери и ръкави

- лица

-

Кабели за специални приложения

- Удължителни и компенсаторни кабели

- Кабели за термодвойки

- Свързващи кабели за PT сензори

- Многожилни кабели темп. -60°C до +1400°C

- Кабели средно напрежение SILICOUL

- Кабели за запалване

- Нагревателни кабели

- Едножилни кабели темп. -60°C до +450°C

- Железопътни проводници

- Нагревателни кабели в Ex

- Кабели за отбранителната промишленост

- Go to the subcategory

- тениски

-

Плитки

- Плоски плитки

- Кръгли плитки

- Много гъвкави плитки - плоски

- Много гъвкави плитки - кръгли

- Цилиндрични медни оплетки

- Медни цилиндрични оплетки и капаци

- Гъвкави ленти за заземяване

- Цилиндрични оплетки от поцинкована и неръждаема стомана

- Медни оплетки с PVC изолация - температура до 85 градуса

- Плоски алуминиеви оплетки

- Комплект за свързване - оплетки и тръби

- Go to the subcategory

- Тягово оборудване

- Накрайници за кабели

- Изолирани гъвкави релси

- Многослойни гъвкави шини

- Системи за управление на кабели

- Go to the subcategory

- View all categories

-

полупроводници

-

-

- Suppliers

-

Applications

- CNC машини

- DC и AC задвижвания (инвертори)

- Двигатели и трансформатори

- Енергетика

- Енергийни банки

- Заваръчни машини и заварчици

- Захранвания (UPS) и токоизправителни системи

- Измерване и регулиране на температурата

- Изследвания и лабораторни измервания

- Индукционно нагряване

- Индустриална автоматизация

- Индустриална защитна екипировка

- Компоненти за зони с опасност от експлозия (EX)

- Машини за сушене и обработка на дървесина

- Машини за термоформоване на пластмаси

- Минно дело, металургия и леярство

- Оборудване за разпределителни и контролни шкафове

- ОВК автоматизация

- Печат

- Трамвайна и железопътна тяга

-

Инсталация

-

-

Индуктори

-

-

Индукционни устройства

-

-

Обслужване

-

- Contact

- Zobacz wszystkie kategorie

The Intelligent Power Module Concept for Motor Drive Inverters

The Intelligent Power Module Concept for Motor Drive Inverters

Designers of inverters for small AC motors in consumer and general purpose industrial applications are required to meet increasingly challenging stringent efficiency, reliability, size, and cost constraints. Classically, many of such small inverter designs utilize discrete power device packages along with the necessary auxiliary components needed to realize the interface, drive, and protection functionalities.

By Philipp Jabs and Muzaffer Albayrak, Mitsubishi Electric Europe B.V., Ratingen, Germany

With this approach, relatively large and complex PCB designs are required to meet all of the spacing and layout requirements of the drivers and discrete power devices combination. Another equally perplexing problem is maintaining consistent performance and reliability when the characteristics of the drivers and power devices are not properly matched. An alternative solution to these problems is to use an integrated power module that contains all the required power devices along with matched gate drivers and protective functions integrated in low-voltage and high-voltage ICs (LVIC & HVIC). Finally, the fully integrated package solution allows to decrease the stock handling and reduces the assembling time compared to a discrete solution.

Building on the success of its Intelligent Power Module (IPM) approach, Mitsubishi Electric pioneered the DIPIPM™ concept in 1997 based on assembling bare power chips and LV/HVICs using a compact transfer moulded lead frame design to maintain optimized and consistent reliable performance while addressing the module’s lowcost requirements.

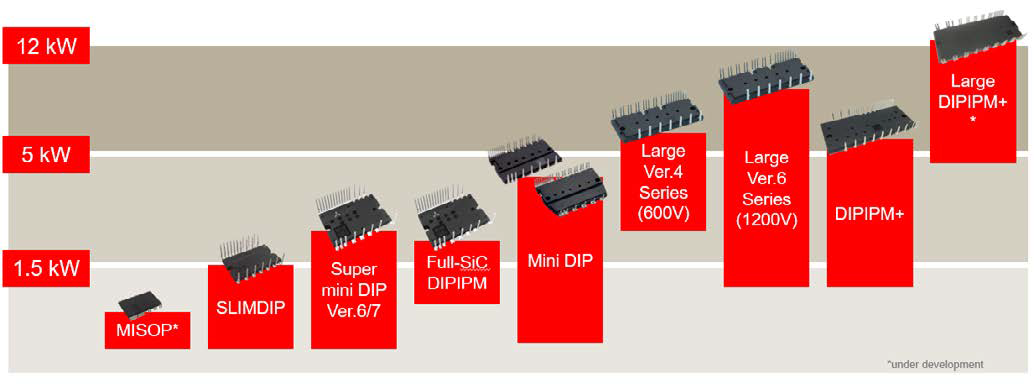

Figure 1: Current DIPIPM lineup

Extending the family recently with the surface mounted SP2SK module and the high current rated Large DIPIPM+, the line-up of Mitsubishi Electric’s transfer moulded IPMs covers a power range from several tens of watts up to more than 12 kW as shown in Figure 1.

Topology and protection functions

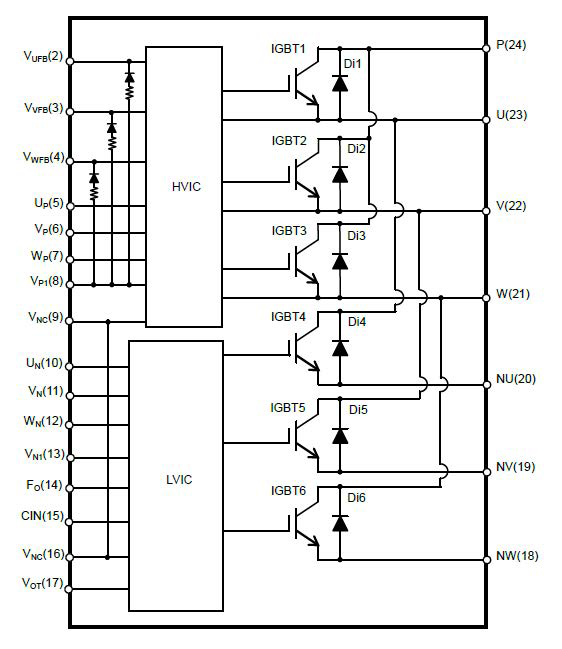

Nowadays, the topologies of hard switching motor drivers in the lower power range are similar. For an optimum of costs and reliability, the amount of used semiconductors is desired to be as low as possible. The solution to be found in nearly all types of servo drives, home appliance inverters, fan inverters and pump inverters is the three phase full bridge using Insulated Gate Bipolar Transistors (IGBT). The advantage of using IGBT is the high blocking capability combined with lower conducting losses, compared to the MOSFET technology. Figure 2 shows the topology exemplarily used in the Super Mini DIPIPM™ series.

Figure 2: Topology integrated in the Super Mini DIPIPM™ series

The market for consumer and industrial products is getting more and more dynamic. Trends of smart home technologies and also industry 4.0 (IoT) requirements lead the designer to develop the next generation inverters in short time and more cost efficient. Here, Mitsubishi Electric’s transfer-mould modules outperform in the market with their highly-integrated features, easy-to-implement and cost-competitive solution. They enable to shrink the inverter due to the compact module outline and sophisticated pin design with well-designed clearance and creepage distances. Furthermore, the line-up with the different series offers the possibility to design a scalable platform inverter, as several current ratings of each series are available. With offered blocking voltages of 600V and 1200V, commonly used single and three phase applications are covered. With the UL recognized isolated thermal interface with a rating of 2.5kV (1.5kV for the SP2SK module) and a low thermal impedance, the effort for a user-safe design is lowered, covering also the higher requirements for industrial use. Furthermore, the mechanical stress in the module is heavily decreased with the use of organic material, as the thermal expansion coefficients are better matched in comparison with ceramic materials. For high power ratings, an additional internal heatsink is moulded in the module for better heat spreading.

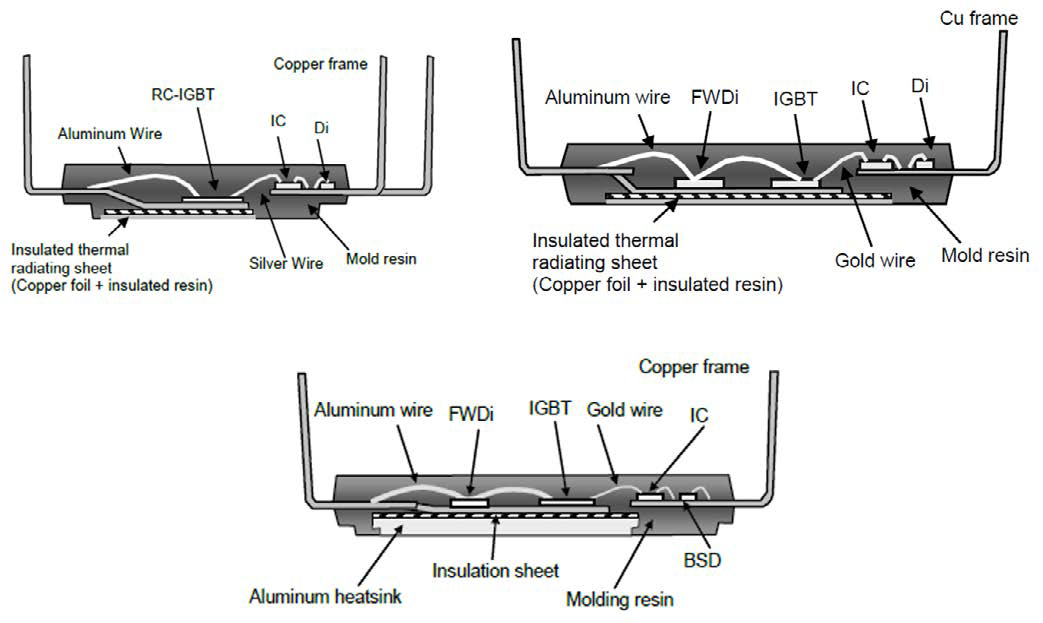

Figure 3: Internal structure (clockwise): SLIMDIP™, Super Mini DIPIPM™ and Large DIPIPM™

Mitsubishi Electric’s modules consists of six IGBT with separate freewheeling diodes or six reverse-conducting IGBT (RC-IGBT). For the easy control of the IGBT, one or three high side driver ICs, a low side driver IC and, depending on the series, three bootstrap diodes with current limiting resistors are integrated. Due to the level shifter integrated in the HVIC, the transfer moulded modules from Mitsubishi Electric can be powered by a single 15V supply voltage source and can be controlled directly by an MCU without the need of galvanic isolation to control the high side switches. All dies are directly mounted on the lead frame without using a PCB inside the module, offering a market leading lifetime performance.

The emitter of the low side IGBT are open, enabling an independent current measurement of each single motor phase by the use of shunt resistors. With the possibility of detecting the three phase currents independently, state-of-the-art position-sensor less machine control can be used in the control framework of the user. The output signals of the current Measurement shunts are additionally used for the internal short circuit protection, which prevents the module to operate out of the short-circuit safe area of operation (SCSOA). Furthermore, the modules integrate a temperature output with a linear temperature-voltage dependency, resulting in an easy-to-implement condition monitoring and offering the possibility to integrate a dynamically controlled de-rating and the optional over temperature protection.

All of Mitsubishi Electric’s transfer moulded modules leaving the production line are tested regarding their static and dynamic electrical characteristics and undergo a functional test with an inductive load, which help to reach a high level quality of delivered products. All results are recorded in an individual end-of-line test report in the factory.

Packages

Motor inverters are found in very different kinds of applications. Mitsubishi Electric offers different packages and herewith the optimal solution for each requirement.

The module with the smallest outline is the surface mount SP2SK module. Additionally to the common protection features of the DIPIPM™ family, an interlock protection is integrated, preventing an arm shoot-through if high and low side switch is turned on. With the compactness of this module due to the used RC-IGBT, it is perfectly suited for low power single phase applications like dish washer or fans.

If a higher power rating is targeted, the SLIMDIP™ package is optimal. As well using the same RC-IGBT technology, it offers an outstanding compactness with through-hole technology. Matching the requirements of price sensitive platform inverters used in home appliances with a power range between 0.5kW and 1.5kW combined with a sophisticated pin design, the time-to-market is highly decreased.

With the Super Mini DIPIPM™ package, Mitsubishi Electric set a market standard for transfer mould IPM modules. It covers a wide range of current ratings, allowing the precise choice of the optimal suited module. As a highlight, additionally to the choice between silicon IGBT and silicon MOSFET models, two SiC MOSFET modules are available, based on Mitsubishi Electric’s long term experience with silicon carbide.

The Mini DIPIPM™ packages allow due its bigger package an even better heat dissipation and therefore higher power rating. Moreover, the increased pin distances allow the use of 1200V IGBT in some models.

The Large DIPIPM™ package targets high power inverters where space is limited and a PCB based design is preferred. Blocking voltages of 600V and 1200V are offered with a wide current range.

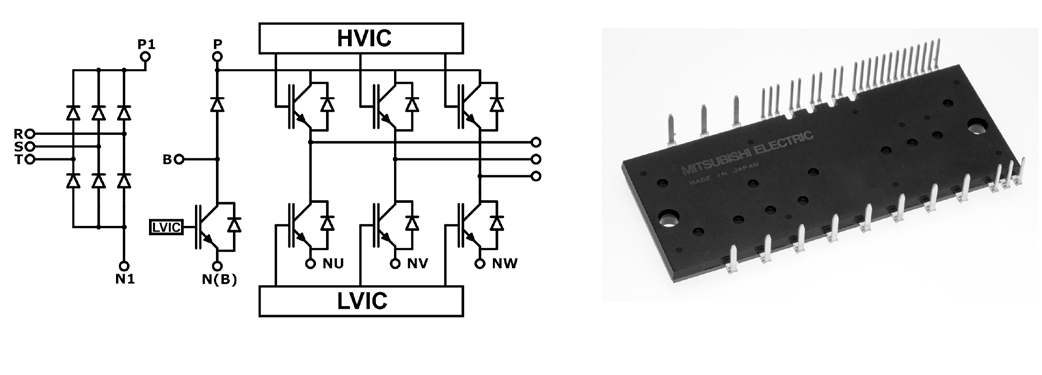

Figure 4: DIPIPM+ schematic (left) and package (right)

The DIPIPM+™ and Large DIPIPM+™ is one of the latest developments. Based on Mitsubishi Electric’s experience and knowledge, the package contains a three phase rectifier, a three phase full bridge and an optional brake IGBT. With the highest level of integration and compactness, it is the package which the user the most complete solution, shortening the component decision process and lifetime evaluation.

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Leave a comment