Трябва да сте влезли в

Category

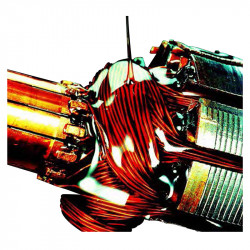

Снимките са само с информационна цел. Вижте спецификацията на продукта

please use latin characters

Application:

- electrical devices, which need insulation class F and H,

- motors for hermetic sets,

- magnetic sheets gluing. .

Main characteristics:

- this impregnated lacquer, straw colour, made on the epoxide resin base, has great adhesion preferences, which allow for good glueing enamel windings and transformers.

- has great resistance for diluent

- lacquer E 524 TS is not toxic, and completely resistant FREON 22

- it also has certification for its resistance for piralen,

- it is adequate for enamel wires class B,

Impregnation:

- preliminary object heat up to temperature 40 4 50°C

- object immersion until there are no air blisters.

- dripping for a short period of time depending on the object weight.

Polymerisation:

- 1 hour @ 110°C (object temperature),

- temperature rise up to 160°C,

- keeping temperature 160°C for 1,5 - 4 hours. (depends on object).

If operation conditions require this, it is possible to act in two phases:

- after impregnation and dipping, first drying at 110C is to evaporate diluent and preliminary polymerisation.

- Polymerisation can be made later, even after some storage time.

Storage conditions:

12 months in original and closed package, far away from the sun and heat source.

Packing:

- in containers 1, 5, 30 l or in barrels 200l.

|

Thermal indicator E 524 TS on the screw coil.

- ASTM D 3145.

enamel wire 300 HAX ThermkO.

|

Thermal indicator E 524 TS for twist

- ASTM D 3245.

enamel wire 300 HAX Thermk O.

|

|

|

Интересувате ли се от този продукт? Имате ли нужда от допълнителна информация или индивидуални цени?

Трябва да сте влезли

Application:

- electrical devices, which need insulation class F and H,

- motors for hermetic sets,

- magnetic sheets gluing. .

Main characteristics:

- this impregnated lacquer, straw colour, made on the epoxide resin base, has great adhesion preferences, which allow for good glueing enamel windings and transformers.

- has great resistance for diluent

- lacquer E 524 TS is not toxic, and completely resistant FREON 22

- it also has certification for its resistance for piralen,

- it is adequate for enamel wires class B,

Impregnation:

- preliminary object heat up to temperature 40 4 50°C

- object immersion until there are no air blisters.

- dripping for a short period of time depending on the object weight.

Polymerisation:

- 1 hour @ 110°C (object temperature),

- temperature rise up to 160°C,

- keeping temperature 160°C for 1,5 - 4 hours. (depends on object).

If operation conditions require this, it is possible to act in two phases:

- after impregnation and dipping, first drying at 110C is to evaporate diluent and preliminary polymerisation.

- Polymerisation can be made later, even after some storage time.

Storage conditions:

12 months in original and closed package, far away from the sun and heat source.

Packing:

- in containers 1, 5, 30 l or in barrels 200l.

|

Thermal indicator E 524 TS on the screw coil.

- ASTM D 3145.

enamel wire 300 HAX ThermkO.

|

Thermal indicator E 524 TS for twist

- ASTM D 3245.

enamel wire 300 HAX Thermk O.

|

|

|

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Напишете свой отзив

Review sent

Your review cannot be sent