Czujniki dymu montowane w kanałach wentylacyjnych stanowią kluczowy element systemów bezpieczeństwa pożarowego w budynkach. Ich zadaniem jest szybkie wykrycie zadymienia w kanałach wentylacyjnych – zanim dym rozprzestrzeni się dalej w instalacji. Jednym z najbardziej zaawansowanych urządzeń tego typu jest Calectro UG8-E-24, dostępny w ofercie DACPOL, projektowany z myślą o niezawodności, prostocie montażu oraz długiej pracy bez fałszywych alarmów. Dostępny również w wersji 230 V AC: Calectro UG8-E-230.

Компоненти за електроенергетика, автоматика, електроника, електротехника. Над 140 водещи производители.

Доставчици

Вижте всички доставчиципродуктови категории

Вижте всички категорииПоследни публикации

-

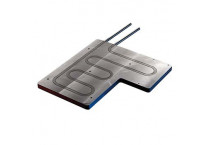

Водородни горивни клетки – приложениеRead more

Статията описва водородните горивни клетки – технология за ефективно и екологично преобразуване на водорода в електрическа енергия. Разглеждат се принципите на работа на клетките, тяхното приложение в автомобилостроенето, промишлеността и енергетиката, както и предимствата им – бързо зареждане, голям пробег и възможност за интеграция с възобновяеми енергийни източници. Технологията представлява обещаващо решение за устойчиво развитие и енергийния преход.

-

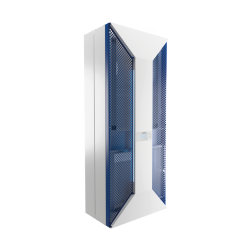

Как охлаждането и климатизацията на шкафовете влияят на живота на електронните компонентиRead more

Статията разглежда значението на охлаждането и климатизацията на контролни шкафове за поддържане на живота на електронните компоненти. Обяснява как стабилната температура и влажност подобряват надеждността на промишлените системи, описва различни методи за охлаждане, ролята на дизайна на шкафа и разположението на компонентите и подчертава енергийната ефективност в модерните промишлени инсталации.