Musíte být přihlášen

Category

Fotografie slouží pouze pro informační účely. Zobrazit specifikaci produktu

please use latin characters

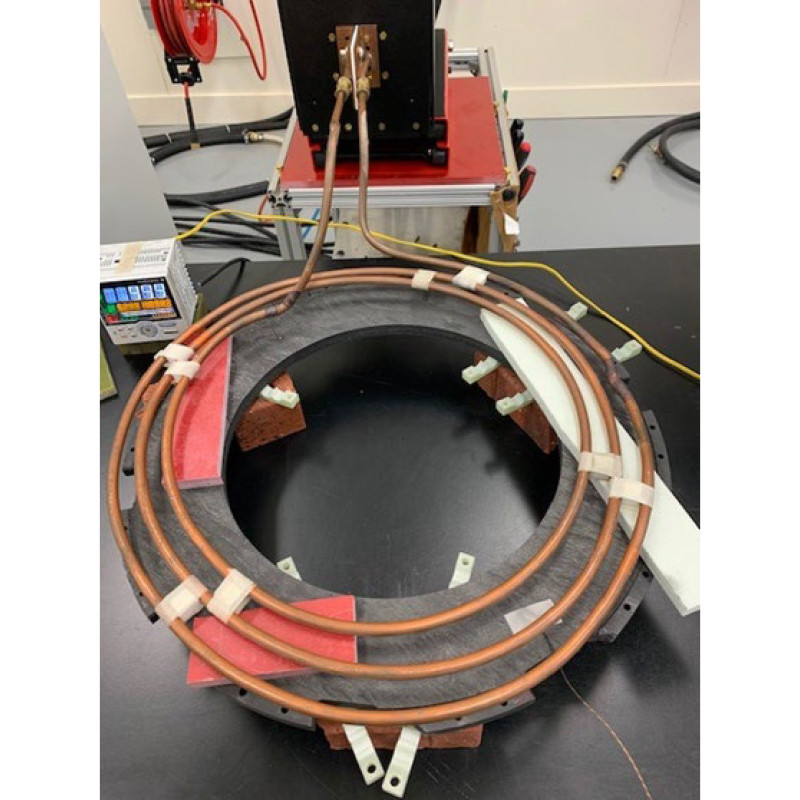

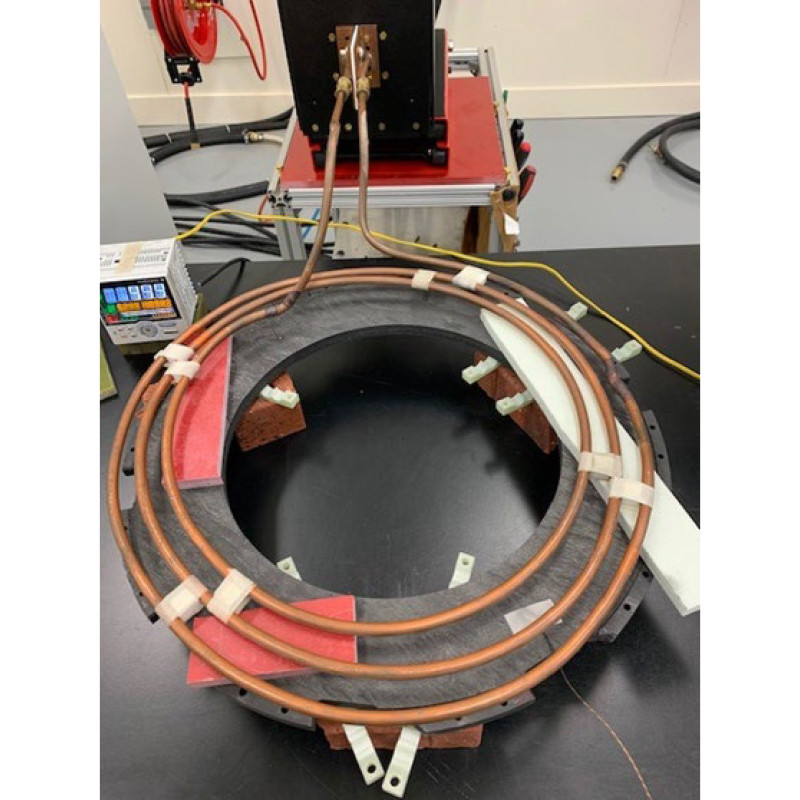

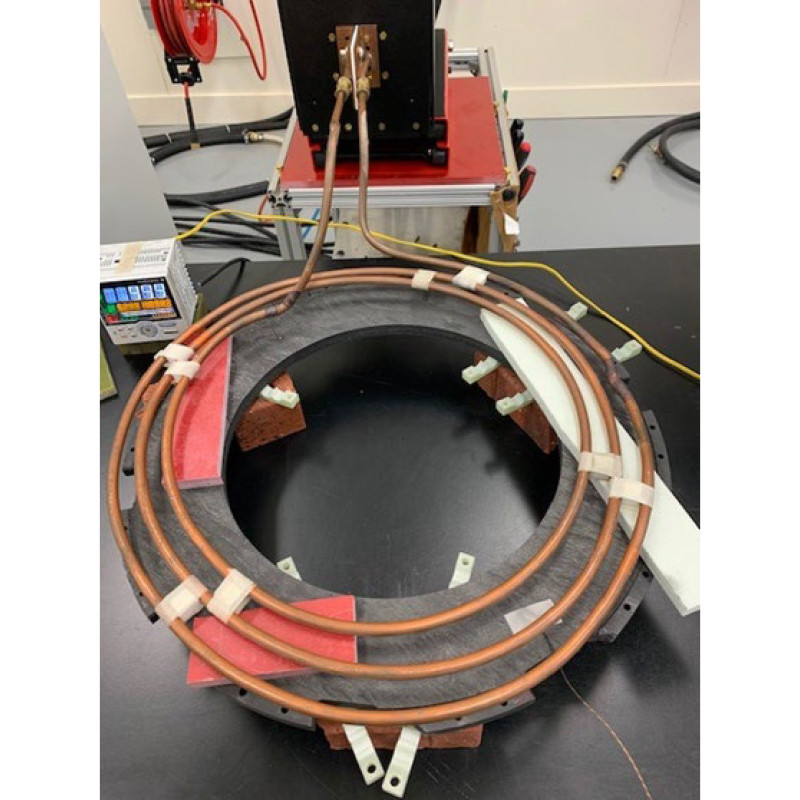

Objective: To heat an assortment of graphite discs of variable sizes; the client was from the aerospace industry.

Material: Graphite discs

Temperature: 200 ºF (93 ºC)

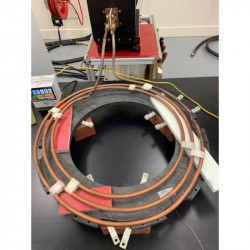

A custom-designed single position multiple-turn pancake coil was built to generate the required heating for this application. Initial tests were conducted to optimize the power delivered to the part. The coil was held 0.5” (12.7 mm) above the top surface of the part. Thermocouples were attached to the top and bottom surfaces of the part. It took 45 seconds to heat the sample to the target temperature of 200 °F (93 °C) on the surface closest to the coil. The surface farther from the coil reached 180°F (82 °C) in this time. It is possible to use closed-loop temperature control with the EKOHEAT to bring the top surface to temperature and hold it while the farther surface is brought to temperature.

Máte zájem o tento produkt? Potřebujete další informace nebo individuální ceny?

musíš být přihlášen

Objective: To heat an assortment of graphite discs of variable sizes; the client was from the aerospace industry.

Material: Graphite discs

Temperature: 200 ºF (93 ºC)

A custom-designed single position multiple-turn pancake coil was built to generate the required heating for this application. Initial tests were conducted to optimize the power delivered to the part. The coil was held 0.5” (12.7 mm) above the top surface of the part. Thermocouples were attached to the top and bottom surfaces of the part. It took 45 seconds to heat the sample to the target temperature of 200 °F (93 °C) on the surface closest to the coil. The surface farther from the coil reached 180°F (82 °C) in this time. It is possible to use closed-loop temperature control with the EKOHEAT to bring the top surface to temperature and hold it while the farther surface is brought to temperature.

Vaše hodnocení nelze odeslat

Nahlásit komentář

Zpráva odeslána

Váš podnět nelze odeslat

Napište svůj názor

Zkontrolovat před odesláním

Vaši recenzi nelze odeslat