Musíte být přihlášen

Category

Fotografie slouží pouze pro informační účely. Zobrazit specifikaci produktu

please use latin characters

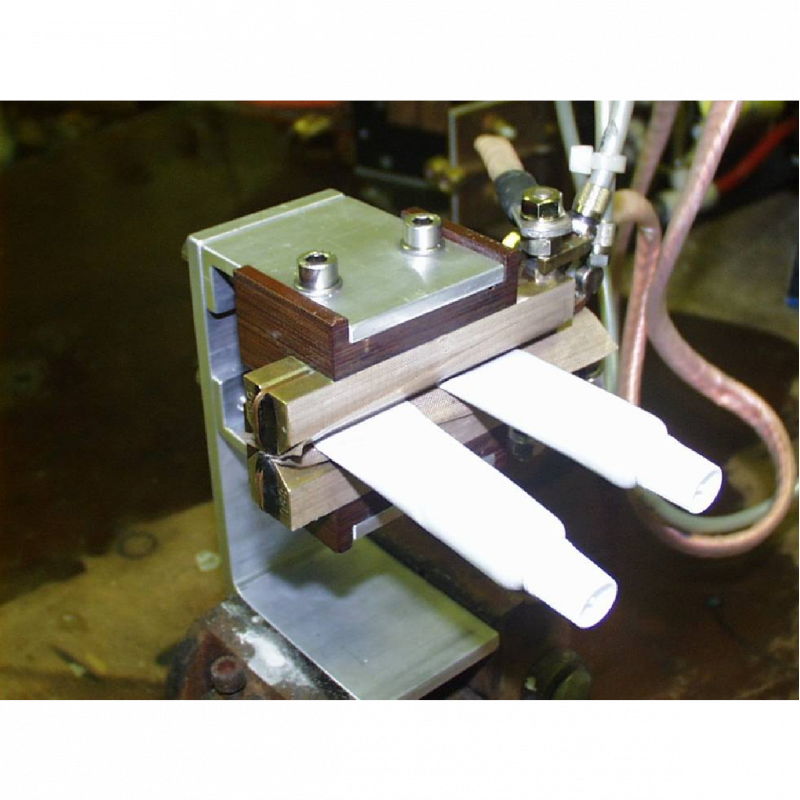

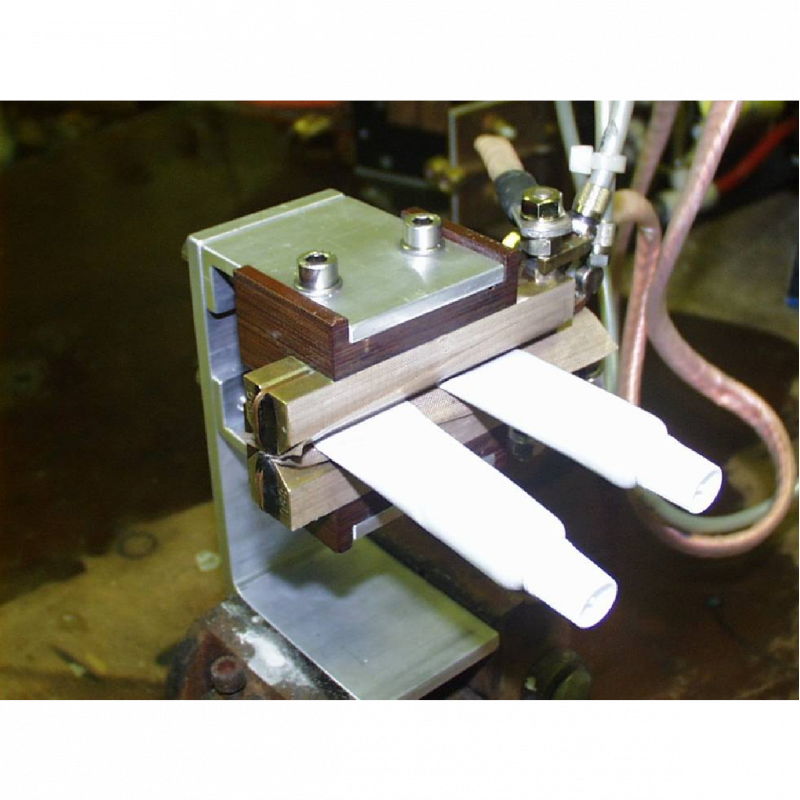

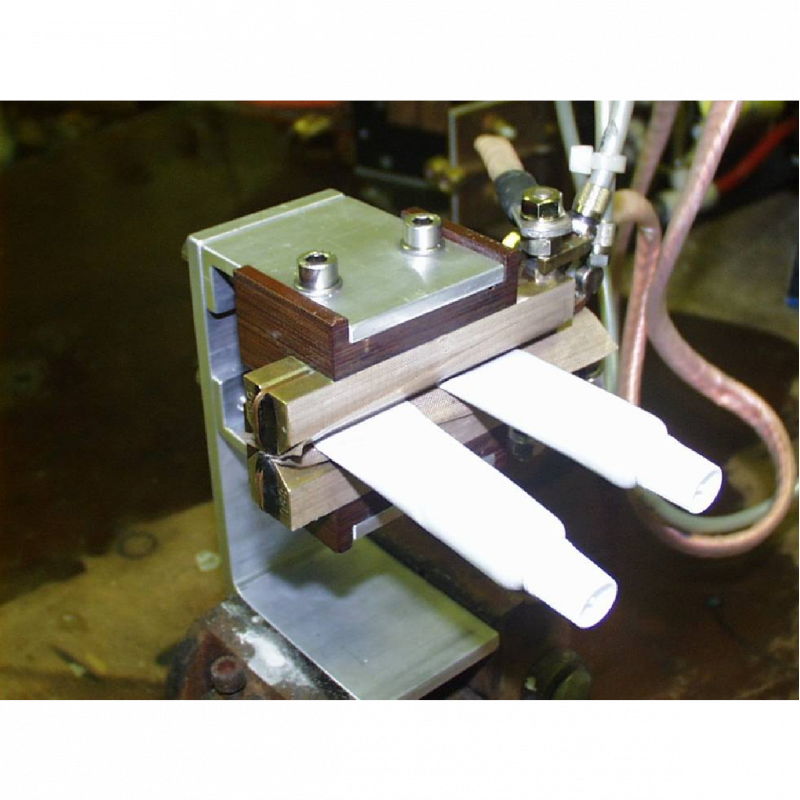

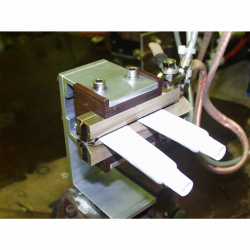

Objective: Melting the end pieces of a plastic tube together to create an air tight seal.

Frequency: 185 kHz

Material: Plastic tube 2.5” (63.5mm) long, 0.75” (19mm) diameter.

A single turn coil encapsulated in custom blocks is used for sealing the tube. Two tubes are placed between the coil blocks and a 7lb (3.2kg) load is applied to the top of the coil. Power is only supplied to the top block of the coil for 250 milli-seconds causing the plastic to melt and create an air tight seal.

Máte zájem o tento produkt? Potřebujete další informace nebo individuální ceny?

musíš být přihlášen

Objective: Melting the end pieces of a plastic tube together to create an air tight seal.

Frequency: 185 kHz

Material: Plastic tube 2.5” (63.5mm) long, 0.75” (19mm) diameter.

A single turn coil encapsulated in custom blocks is used for sealing the tube. Two tubes are placed between the coil blocks and a 7lb (3.2kg) load is applied to the top of the coil. Power is only supplied to the top block of the coil for 250 milli-seconds causing the plastic to melt and create an air tight seal.

Vaše hodnocení nelze odeslat

Nahlásit komentář

Zpráva odeslána

Váš podnět nelze odeslat

Napište svůj názor

Zkontrolovat před odesláním

Vaši recenzi nelze odeslat