Musíte být přihlášen

Category

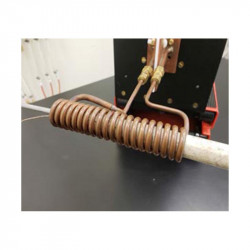

Fotografie slouží pouze pro informační účely. Zobrazit specifikaci produktu

please use latin characters

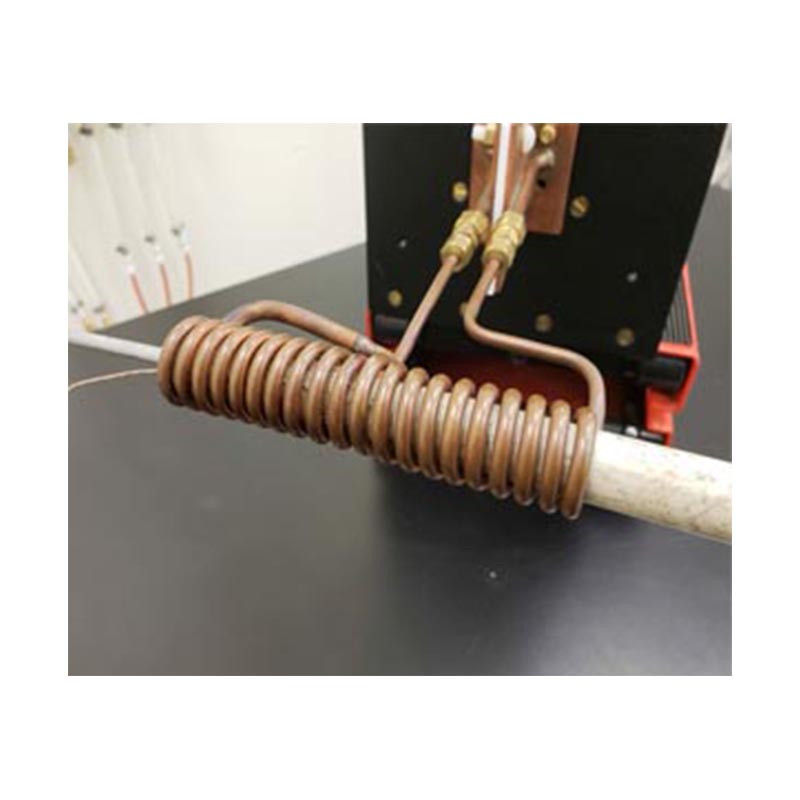

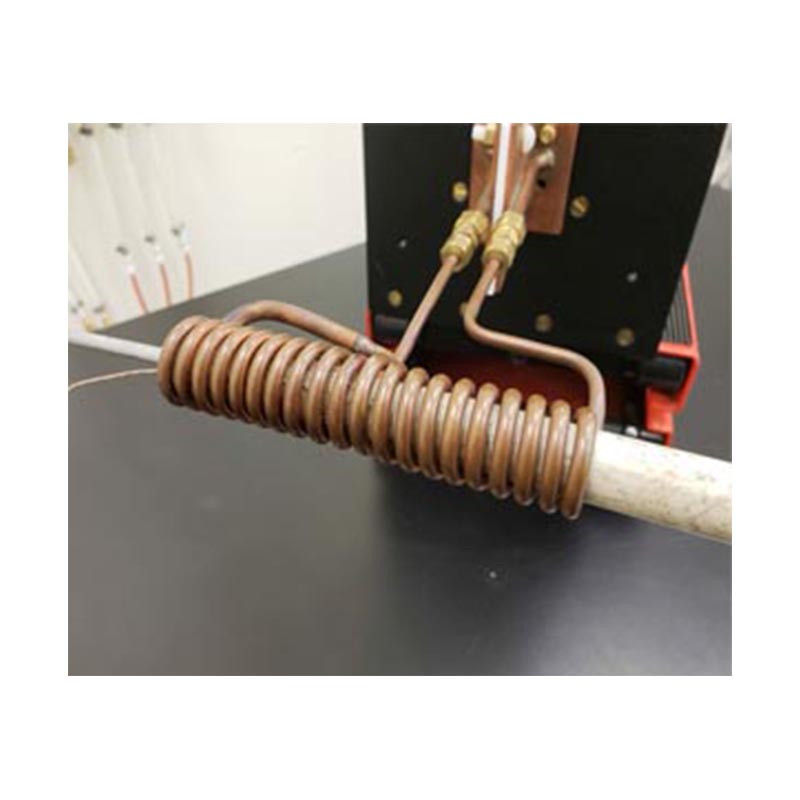

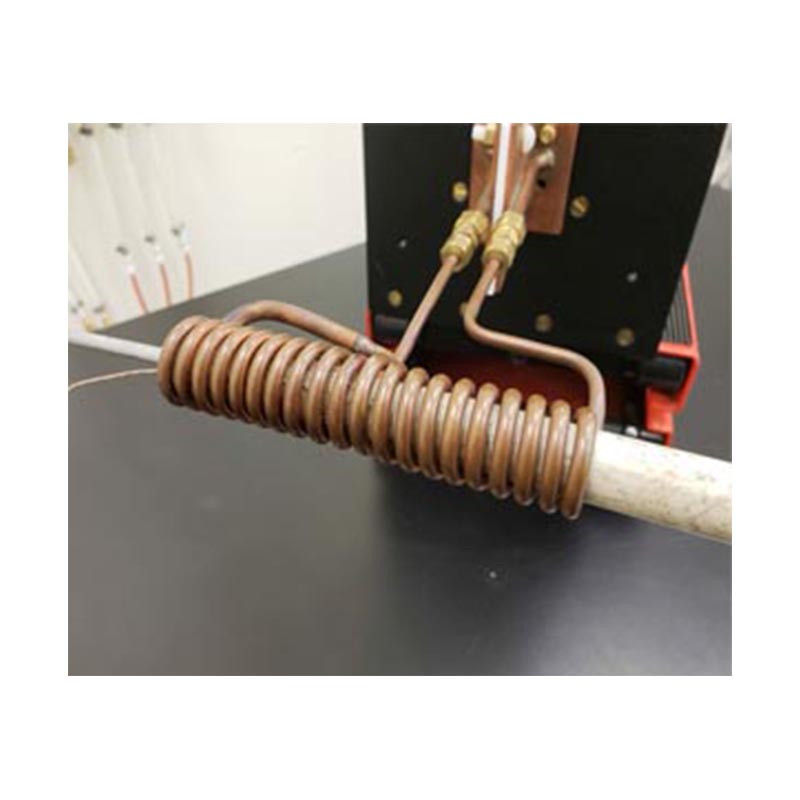

Objective: Preheating steel wire before hot heading to create a screw; they wanted to switch from cold heading to extend tool life.

Equipment: Ambrell EKOHEATⓇ 30 kW, 50-150 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Frequency: 94 kHz

Material: Steel wire (0.214” / 5.4 mm diameter)

Temperature: 350 °F (177 °C)

Testing:

Benefits:

Máte zájem o tento produkt? Potřebujete další informace nebo individuální ceny?

musíš být přihlášen

Objective: Preheating steel wire before hot heading to create a screw; they wanted to switch from cold heading to extend tool life.

Equipment: Ambrell EKOHEATⓇ 30 kW, 50-150 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Frequency: 94 kHz

Material: Steel wire (0.214” / 5.4 mm diameter)

Temperature: 350 °F (177 °C)

Testing:

Benefits:

Vaše hodnocení nelze odeslat

Nahlásit komentář

Zpráva odeslána

Váš podnět nelze odeslat

Napište svůj názor

Zkontrolovat před odesláním

Vaši recenzi nelze odeslat