Musíte být přihlášen

Category

Fotografie slouží pouze pro informační účely. Zobrazit specifikaci produktu

please use latin characters

|

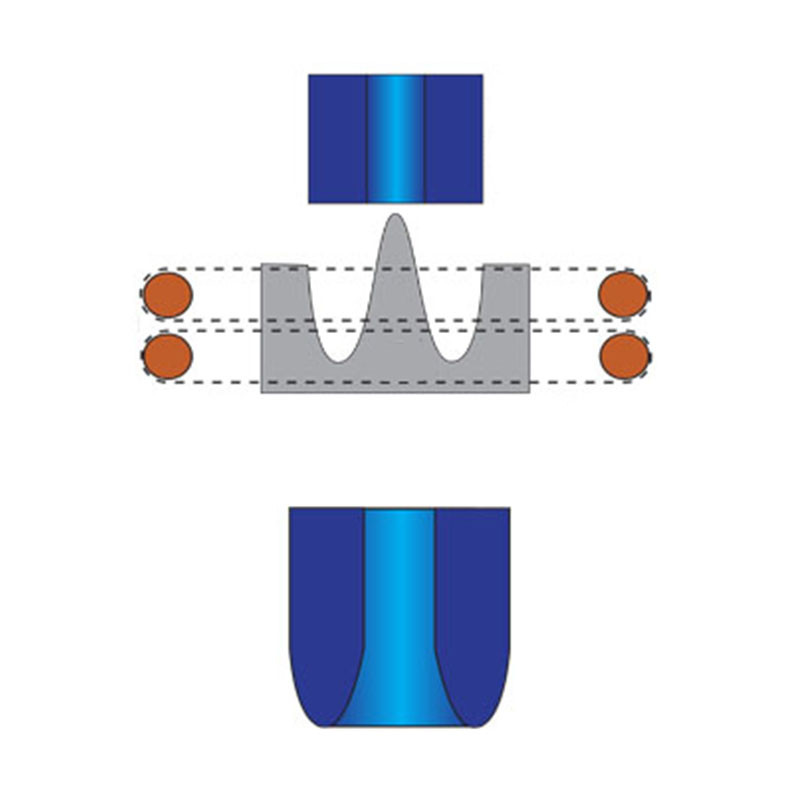

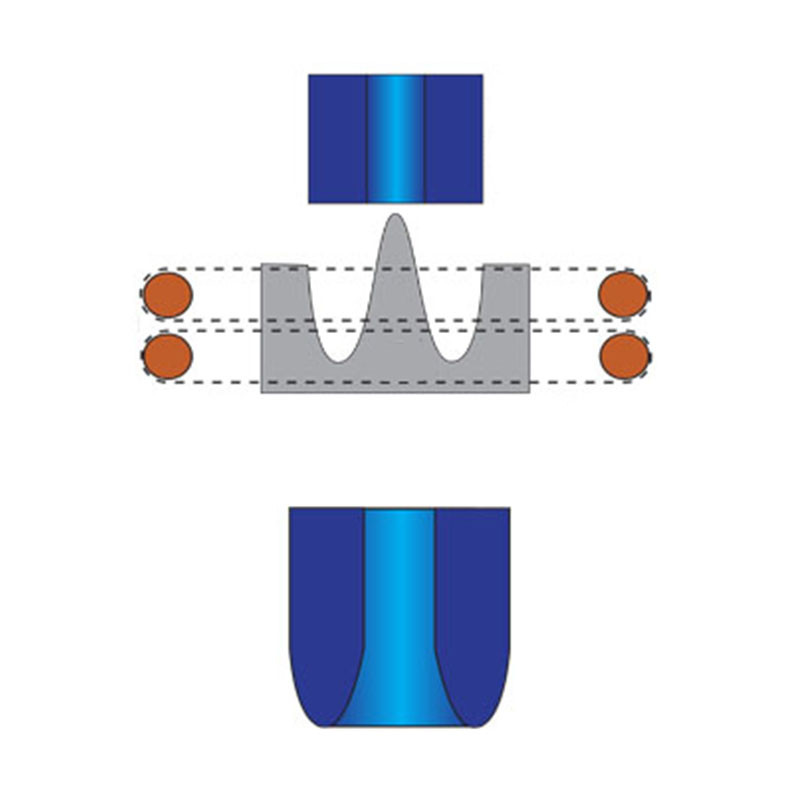

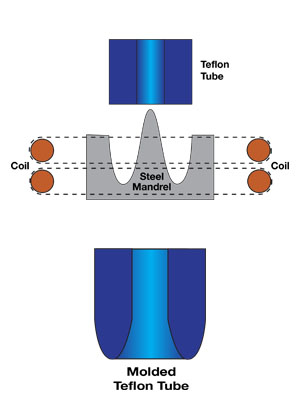

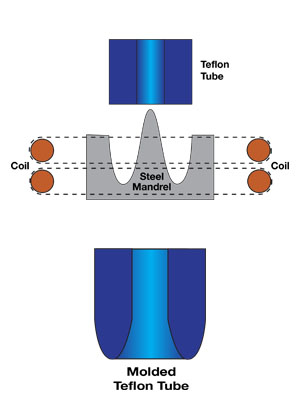

Objective: Heat a water-cooled steel mandrel to 700°F (371ºC) to form a high quality Teflon catheter tip. Material: Teflon catheter tubing, mandrel assembly Temperature: 600-700°F (315.6-371ºC) Frequency: 376 kHz Equipment:

Process: A two turn coil is used to heat the steel mandrel to 660ºF (371.1ºC) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip. Benefits:

|

|

Máte zájem o tento produkt? Potřebujete další informace nebo individuální ceny?

musíš být přihlášen

|

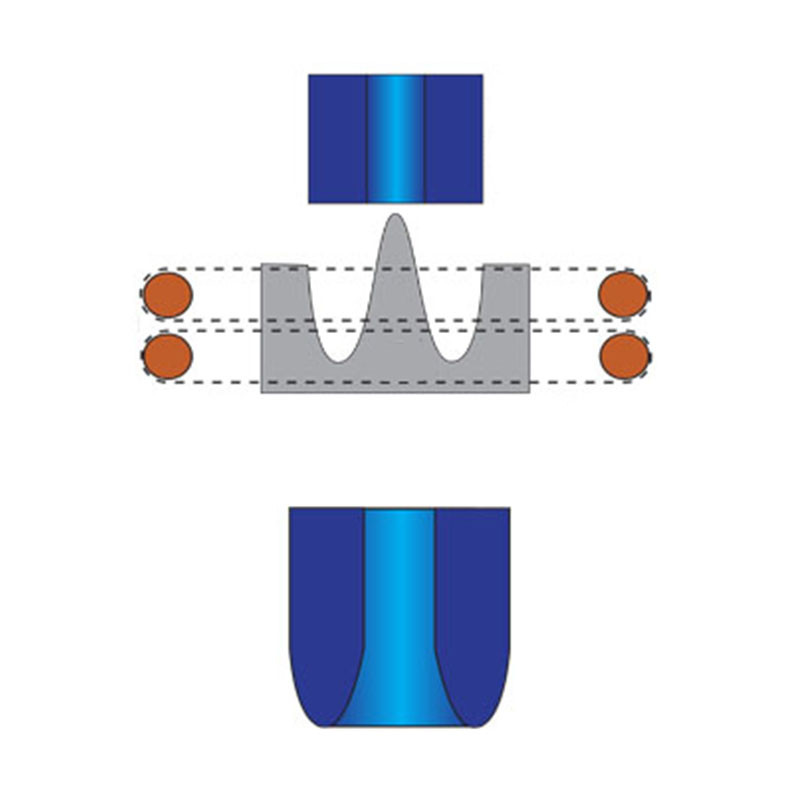

Objective: Heat a water-cooled steel mandrel to 700°F (371ºC) to form a high quality Teflon catheter tip. Material: Teflon catheter tubing, mandrel assembly Temperature: 600-700°F (315.6-371ºC) Frequency: 376 kHz Equipment:

Process: A two turn coil is used to heat the steel mandrel to 660ºF (371.1ºC) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip. Benefits:

|

|

Vaše hodnocení nelze odeslat

Nahlásit komentář

Zpráva odeslána

Váš podnět nelze odeslat

Napište svůj názor

Zkontrolovat před odesláním

Vaši recenzi nelze odeslat