Článek popisuje vodíkové palivové články – technologii, která efektivně a ekologicky přeměňuje vodík na elektrickou energii. Zabývá se principy fungování článků, jejich využitím v automobilovém průmyslu, průmyslu a energetice a výhodami, jako je rychlé doplňování paliva, velký dojezd a možnost integrace s obnovitelnými zdroji energie. Tato technologie představuje perspektivní řešení pro udržitelný rozvoj a energetickou transformaci.

Podsestavy pro výkonovou elektroniku - průmyslová automatizace - elektronika - energie - elektrotechnika

kategorie produktů

Zobrazit všechny kategorieNejnovější příspěvky

-

Jak chlazení a klimatizace rozvaděčů ovlivňuje životnost elektronických komponentRead more

Článek se zabývá významem chlazení a klimatizace rozvaděčů pro udržení životnosti elektronických komponent. Vysvětluje, jak stabilní teplota a vlhkost zvyšují spolehlivost průmyslových systémů, popisuje různé metody chlazení, roli konstrukce rozvaděče a rozmístění komponent a zdůrazňuje energetickou účinnost v moderních průmyslových instalacích.

-

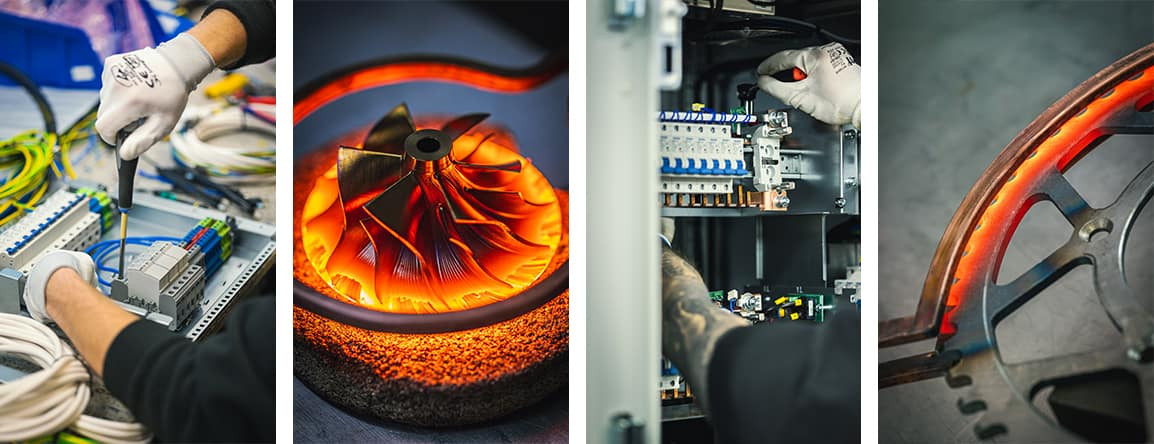

Jak indukční zařízení mění výrobní procesy?Read more

Článek vysvětluje princip indukčního ohřevu a ukazuje, proč je tato technologie stále častěji využívána v moderním průmyslu. Popisuje konstrukci a fungování indukčních zařízení, jejich hlavní výhody oproti tradičním metodám ohřevu i široké spektrum využití – od kalení a pájení až po tavení kovů a laboratorní testy. Článek rovněž přibližuje možnosti společnosti DACPOL SERVICE a zdůrazňuje její roli technologického partnera při návrhu, implementaci a servisu indukčních ohřevných systémů.

![Komponenty pro nebezpečné oblasti a výbušné atmosféry [Ex]](https://www.dacpol.eu/c/6823-catsmal_default/komponenty-pro-nebezpecne-oblasti-a-vybusne-atmosfery-ex-.jpg)