Musíte být přihlášen

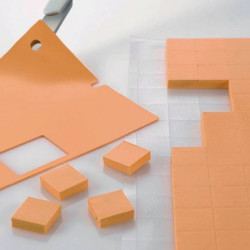

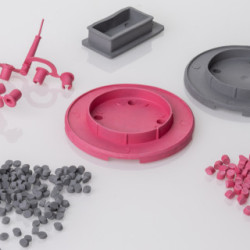

Tepelně vodivé materiály

Kategorie

Firma DACPOL nabízí široký sortiment tepelně vodivých materiálů. Naši zákazníci vědí již mnoho let, že se mohou spolehnout na kvalitu našich produktů. Neustále se snažíme, aby proces objednávání a nákupu z oddělení skříní byl pro naše zákazníky co nejpohodlnější, proto umožňujeme objednávání přes internet a telefon.

Jaké jsou základní parametry tepelně vodivých materiálů?

Nejdůležitějšími parametry charakterizujícími tepelně vodivé materiály jsou:

Teplotní vodivost – je to množství přenesené energie, které závisí na materiálu a je úměrné průřezu překážky, rozdílu teplot, době toku a nepřímo úměrné tloušťce překážky.

Teplotní impedance – je to rozdíl teplot mezi prvkem vydávajícím teplo a chladícím prvkem; hodnota impedance závisí na přítlačné síle a velikosti a kvalitě spojovaných ploch.

Další faktory, které je třeba vzít v úvahu při navrhování systémů, jsou:

- elektrický odpor (izolace a rezistence)

- mechanická pevnost (odolnost proti požáru a nárazům)

- průměrný a maximální rozptyl výkonu

- maximální provozní teplota

- účinnost chladicího systému,

- hladkost/poréznost chladicí plochy.

Jaké druhy tepelně vodivých materiálů rozlišujeme?

Tepelně vodivé lepidla – jsou to speciální lepidla přizpůsobená pro práci v náročných podmínkách, která netají a nevysychají, takže neztrácejí své vlastnosti. Použití lepidla zlepšuje odvod tepla a také upevnění konstrukčních prvků.

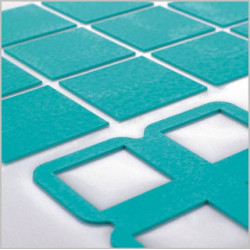

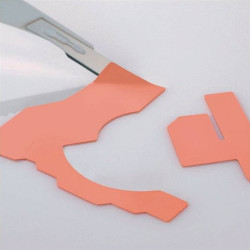

Výplně spár (GFL) – jsou to tepelné směsi, které lze použít k utěsnění zařízení a také k nanášení na radiátory nebo kryty skříní. Jejich důležitou výhodou je snadná aplikace, která umožňuje zabezpečení složitých geometrií. Pomocí těchto materiálů se obvykle vytváří tzv. „vodivostní cesta“.

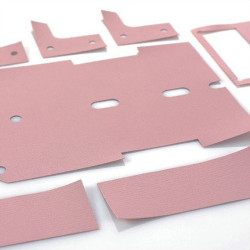

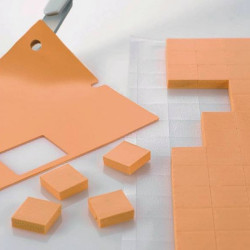

Výplňové materiály – jsou to výplně spár s konkrétní geometrií a mechanickými a elektrickými vlastnostmi umožňujícími jejich použití v různých aplikacích. Jsou přizpůsobeny kompenzaci nerovností komponent a nacházejí uplatnění v aplikacích citlivých na tlak.