Musíte být přihlášen

Category

Fotografie slouží pouze pro informační účely. Zobrazit specifikaci produktu

please use latin characters

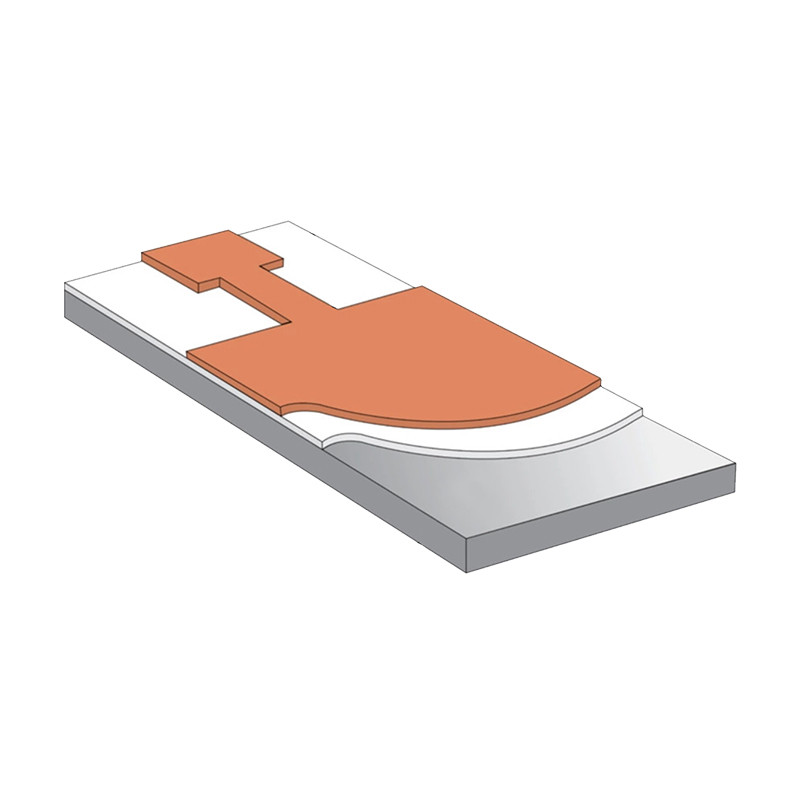

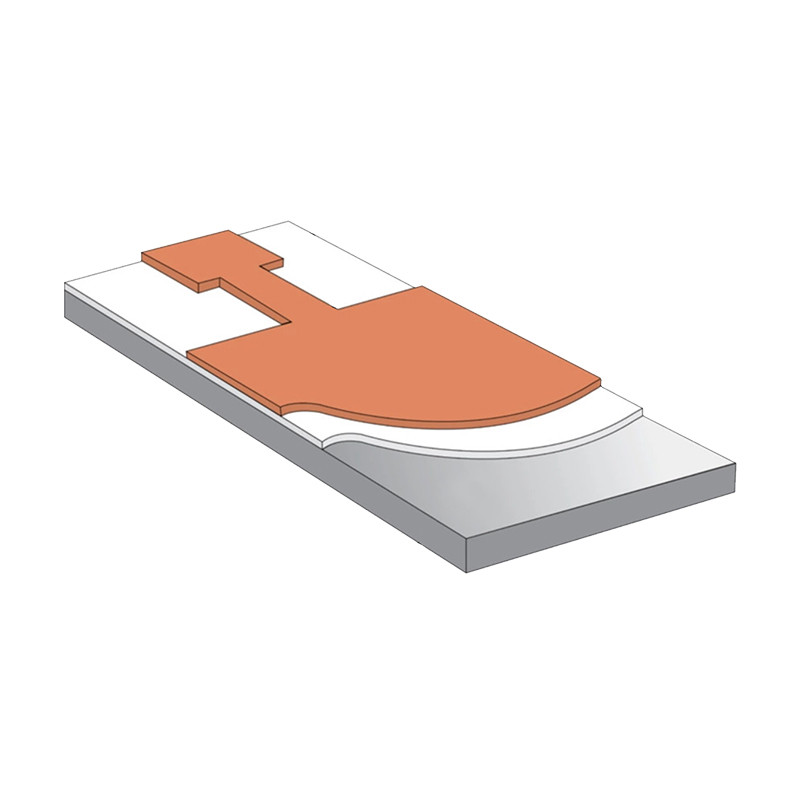

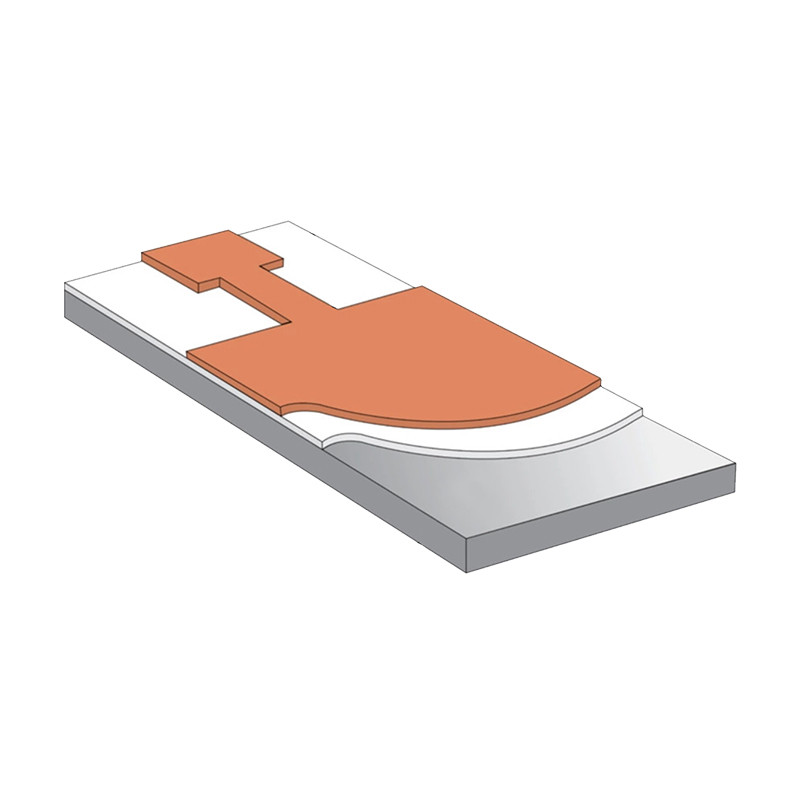

Thermal Clad is a versatile substrate allowing circuit boards to be configured for shapes, bends and multiple thicknesses. In this motor control application, the dielectric has been selectively removed and the metal formed with three-dimensional features.

Additional Thermal Clad benefits:

• Increased power density

• Extend the life of dies

• Improved product thermal and mechanical performance

• Better use of surface mount technology

Anatomy of a Thermal Clad Board:

1. Base layer Copper 0,51 - 4,83 mm oa Aluminium 0,51 - 3,18 mm.

2. Dielectric layer – HPL, HT, LM, MP.

3. Circuit layer – 35 um – 350 um.

Parameters:

|

Type

|

Thickness

(10-3in/10-6m) |

Impedance

(oC/W) |

Conductivity

(W/m-k) |

Operating

(VAC) |

Breakdown

(kVAC) |

HT-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.0

|

HT-07006 |

6/150

|

0.70

|

2.2

|

960

|

11.0

|

LTI-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.5

|

LTI-06005 |

5/125

|

0.60

|

2.2

|

480

|

9.5

|

MP-06503 |

3/75

|

0.65

|

1.3

|

120

|

8.5

|

Light output of the same LED die on different circuit board materials at a maintained die temperature of 80ºC.

Máte zájem o tento produkt? Potřebujete další informace nebo individuální ceny?

musíš být přihlášen

Thermal Clad is a versatile substrate allowing circuit boards to be configured for shapes, bends and multiple thicknesses. In this motor control application, the dielectric has been selectively removed and the metal formed with three-dimensional features.

Additional Thermal Clad benefits:

• Increased power density

• Extend the life of dies

• Improved product thermal and mechanical performance

• Better use of surface mount technology

Anatomy of a Thermal Clad Board:

1. Base layer Copper 0,51 - 4,83 mm oa Aluminium 0,51 - 3,18 mm.

2. Dielectric layer – HPL, HT, LM, MP.

3. Circuit layer – 35 um – 350 um.

Parameters:

|

Type

|

Thickness

(10-3in/10-6m) |

Impedance

(oC/W) |

Conductivity

(W/m-k) |

Operating

(VAC) |

Breakdown

(kVAC) |

HT-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.0

|

HT-07006 |

6/150

|

0.70

|

2.2

|

960

|

11.0

|

LTI-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.5

|

LTI-06005 |

5/125

|

0.60

|

2.2

|

480

|

9.5

|

MP-06503 |

3/75

|

0.65

|

1.3

|

120

|

8.5

|

Light output of the same LED die on different circuit board materials at a maintained die temperature of 80ºC.

Vaše hodnocení nelze odeslat

Nahlásit komentář

Zpráva odeslána

Váš podnět nelze odeslat

Napište svůj názor

Zkontrolovat před odesláním

Vaši recenzi nelze odeslat