Sie müssen eingeloggt sein

Category

Fotos dienen nur zu Informationszwecken.

please use latin characters

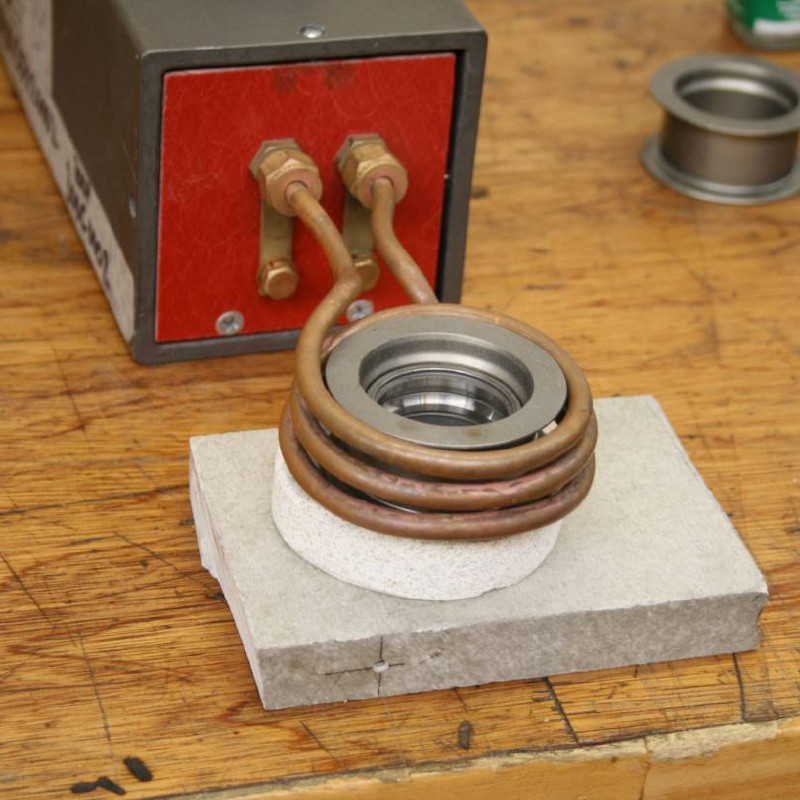

Objective: To heat aluminum pulley for insertion of an inner bearing for the automotive industry.

Frequency: 283 kHz

Material: Aluminum pulley 2.3” (60mm) OD x 1.6” (40mm) ID x 1” (27mm) high and inner bearing 0.7” (17.8mm) high x 1.6” (40mm) dia.

Temperature: 464 °F (240 °C)

A three turn helical coil is used to heat the aluminum pulley. The pulley is heated to 464 ºF (240 ºC) in 20 seconds to expand the inner diameter and then the inner bearing is inserted to form the completed part.

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

Objective: To heat aluminum pulley for insertion of an inner bearing for the automotive industry.

Frequency: 283 kHz

Material: Aluminum pulley 2.3” (60mm) OD x 1.6” (40mm) ID x 1” (27mm) high and inner bearing 0.7” (17.8mm) high x 1.6” (40mm) dia.

Temperature: 464 °F (240 °C)

A three turn helical coil is used to heat the aluminum pulley. The pulley is heated to 464 ºF (240 ºC) in 20 seconds to expand the inner diameter and then the inner bearing is inserted to form the completed part.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Eigenen Kommentar verfassen

Review sent

Your review cannot be sent