Sie müssen eingeloggt sein

Category

Fotos dienen nur zu Informationszwecken.

please use latin characters

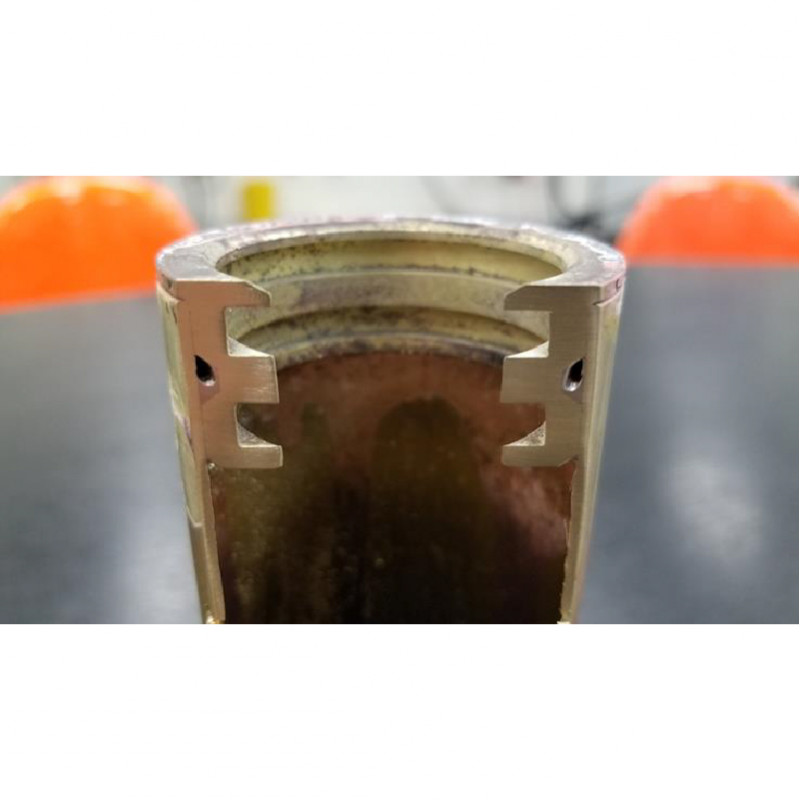

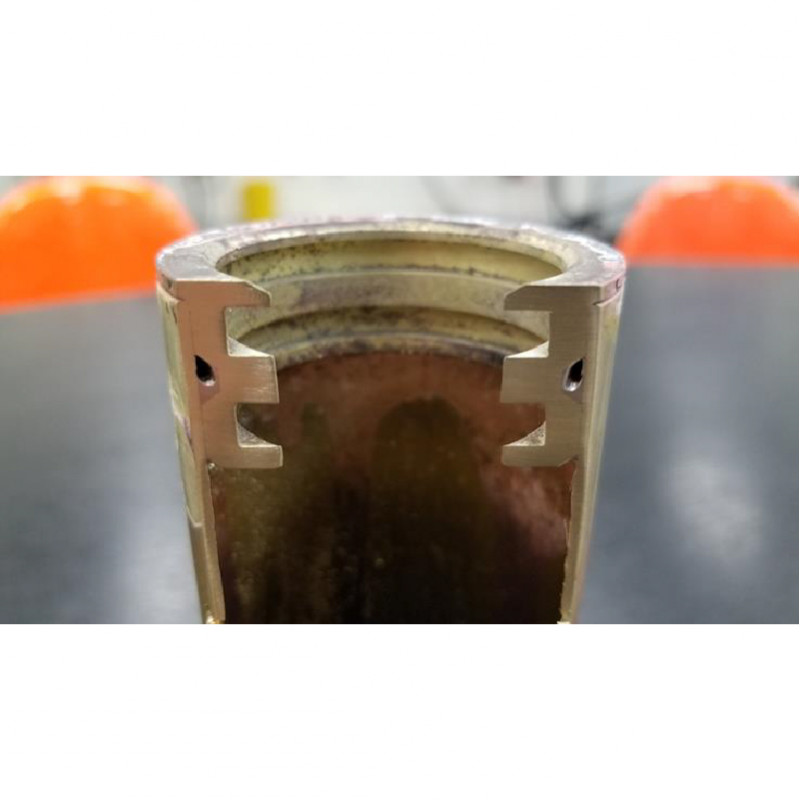

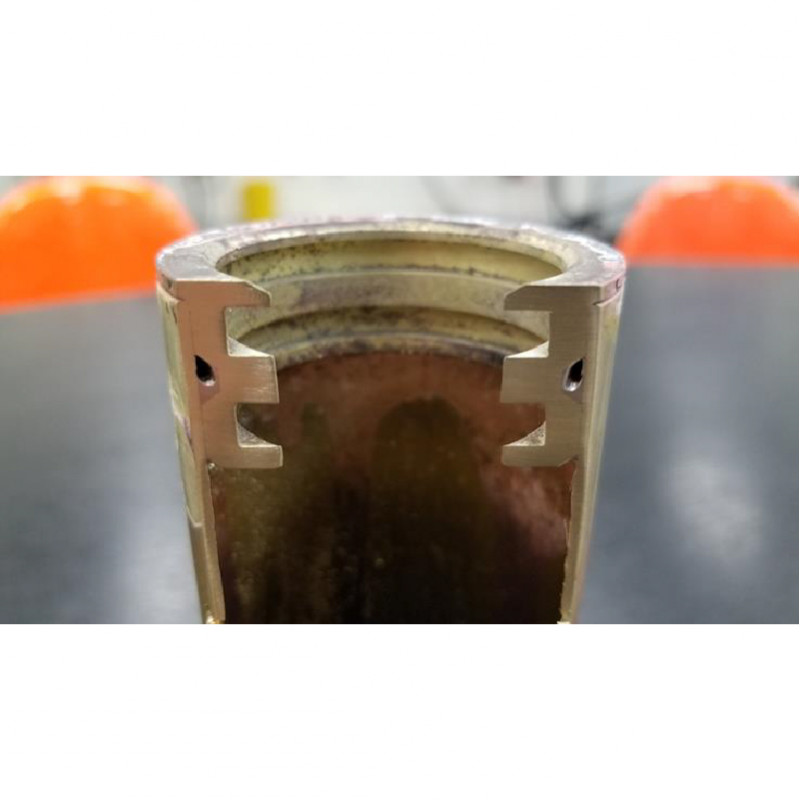

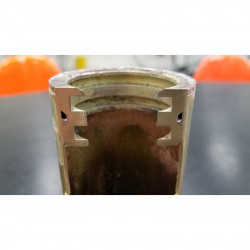

Objective: To heat brass assemblies for a brazing application; the client had been using a torch and is a manufacturer of sink products.

Frequency: 316 kHz

Material: Brass assemblies (2”/51 mm OD)

Temperature: 1425 °F (773 °C)

A custom-designed single position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. It took two minutes to heat the 2”/51 mm OD brass assembly to temperature.

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

Objective: To heat brass assemblies for a brazing application; the client had been using a torch and is a manufacturer of sink products.

Frequency: 316 kHz

Material: Brass assemblies (2”/51 mm OD)

Temperature: 1425 °F (773 °C)

A custom-designed single position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. It took two minutes to heat the 2”/51 mm OD brass assembly to temperature.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Eigenen Kommentar verfassen

Review sent

Your review cannot be sent