Sie müssen eingeloggt sein

Category

Fotos dienen nur zu Informationszwecken.

please use latin characters

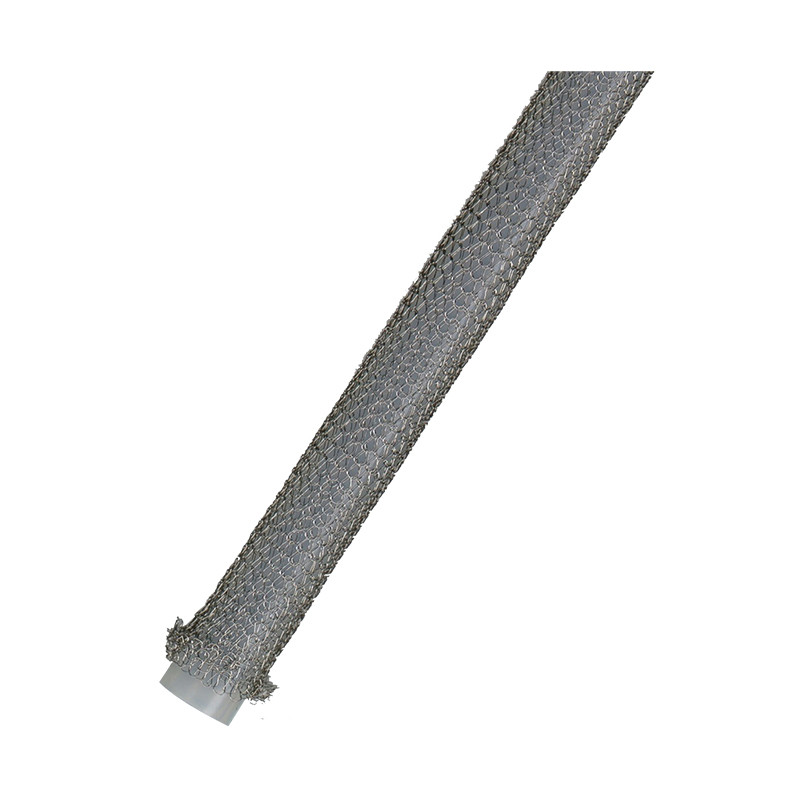

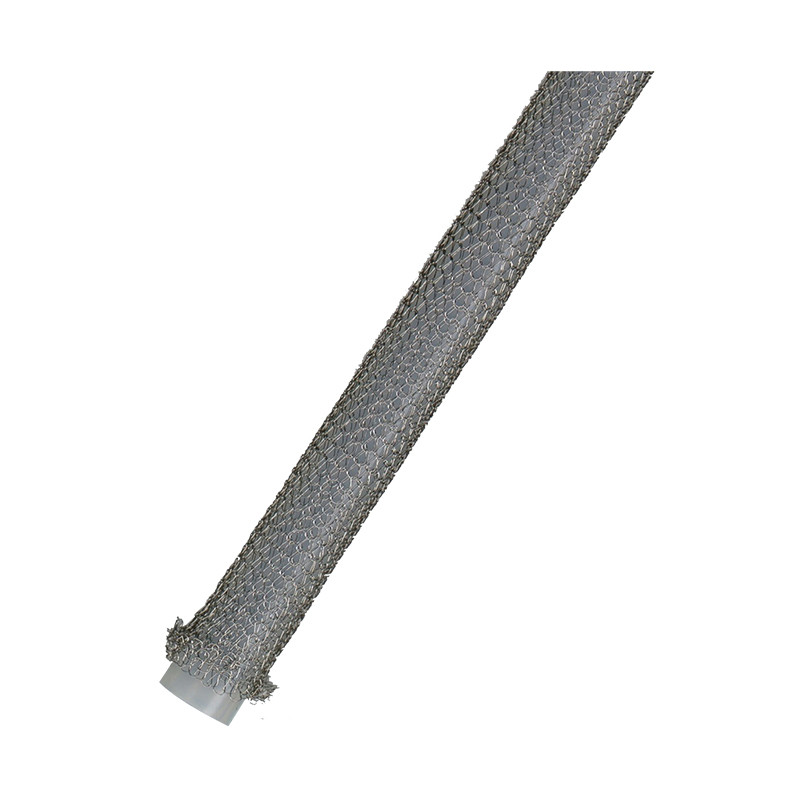

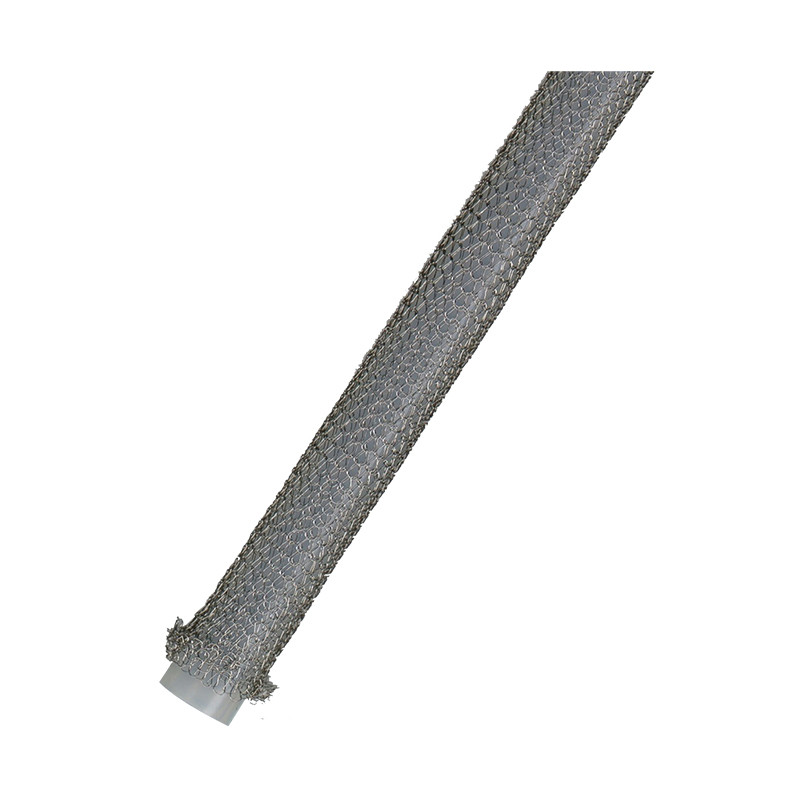

Elastomer core gasketsare made of a resilient rubber core, knitted over by layers of wire mesh (most common istwo layers). The knitted wire element provides EMI shielding effectiveness, while the elastomer core enables the gasket section to recover more quickly, following repeated compressions. Elastomer core gasketsare used where the application requires a conformable EMI seal and even where a dust protection is needed.

Available materials:

Complete the P/N with

2- letters core suffix ; the number of layers (2 is standard) ;

2- letters METAL SUFFIX.

And wire materials:

Mechanical tolerances

1,5-5 mm +0,3 -0,3 mm

5,5-12 mm +0,6 -0,6 mm

>12 mm +0,9 -0,9 mm

BE.048.159.ST.2-MO

double P section, 4.8x15.9 mm , 2 layers of Monel wire over Silicone Tube

Round

| P/N | Diameter [mm] |

|---|---|

TE.016 |

1.6 |

TE.024 |

2.4 |

TE.032 |

3.2 |

TE.048 |

4.8 |

TE.064 |

6.4 |

TE.080 |

8.0 |

TE.095 |

9.5 |

TE.111 |

11.1 |

TE.127 |

12.7 |

TE.159 |

15.9 |

TE.191 |

19.1 |

Rectangular

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

RE.024.024 |

2.4 | 2.4 |

RE.024.048 |

2.4 | 4.8 |

RE.024.064 |

2.4 | 6.4 |

RE.032.032 |

3.2 | 3.2 |

RE.032.064 |

3.2 | 6.4 |

RE.032.080 |

3.2 | 8.0 |

RE.048.048 |

4.8 | 4.8 |

RE.048.080 |

4.8 | 8.0 |

RE.048.127 |

4.8 | 12.7 |

RE.064.064 |

6.4 | 6.4 |

RE.064.127 |

6.4 | 12.7 |

RE.080.127 |

8.0 | 12.7 |

RE.095.127 |

9.5 | 12.7 |

P section

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

PE.032.095 |

3.2 | 9.5 |

PE.032.127 |

3.2 | 12.7 |

PE.032.159 |

3.2 | 15.9 |

PE.032.191 |

3.2 | 19.1 |

PE.048.127 |

4.8 | 12.7 |

PE.048.159 |

4.8 | 15.9 |

PE.048.191 |

4.8 | 19.1 |

PE.048.222 |

4.8 | 22.2 |

PE.080.159 |

8.0 | 15.9 |

PE.080.191 |

8.0 | 19.1 |

PE.080.222 |

8.0 | 22.2 |

PE.080.254 |

8.0 | 25.4 |

PE.095.320 |

9.5 | 32.0 |

DOUBLE P section

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

BE.032.095 |

3.2 | 9.5 |

BE.032.127 |

3.2 | 12.7 |

BE.032.159 |

3.2 | 15.9 |

BE.032.191 |

3.2 | 19.1 |

BE.048.159 |

4.8 | 15.9 |

BE.048.191 |

4.8 | 19.1 |

BE.048.222 |

4.8 | 22.2 |

BE.048.254 |

4.8 | 25.4 |

BE.080.191 |

8.0 | 19.1 |

BE.080.222 |

8.0 | 22.2 |

BE.080.254 |

8.0 | 25.4 |

BE.080.320 |

8.0 | 32.0 |

BE.095.320 |

9.5 | 32.0 |

Shielding performances comparison

This graph compares general performances in E-fieldand H-field screening of four gaskets made of different materials (monel, stainless steel, tinned copper and aluminium). Tests are performed on type T.064.SS.2-XX, with round cross-section and silicone sponge core, in accordance with MIL STD 285

MONEL

Material No. (DIN) 2.4360

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-MO

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 124,5 |

| 10 M | E | 107 |

| 110 M | P | 105,5 |

| 400 M | P | 98 |

| 1 G | P | 82 |

| 10 G | P | 62 |

| Magnetic | ||

| 10 K | H | 37 |

| 100 K | H | 40 |

| 1M | H | 44,5 |

Tinned Copper Clad Steel

ASTM-B-520

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-TC

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Stainless Steel

AISI 304 , Material (DIN) 1.4301

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-SL

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Aluminium

Alloy 5056 , AMS-4182

Wire Diameter 0,13 mm

Test gasket TE.064.SS.2-AL

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Tests performed in accordance with MIL STD 285

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

Elastomer core gasketsare made of a resilient rubber core, knitted over by layers of wire mesh (most common istwo layers). The knitted wire element provides EMI shielding effectiveness, while the elastomer core enables the gasket section to recover more quickly, following repeated compressions. Elastomer core gasketsare used where the application requires a conformable EMI seal and even where a dust protection is needed.

Available materials:

Complete the P/N with

2- letters core suffix ; the number of layers (2 is standard) ;

2- letters METAL SUFFIX.

And wire materials:

Mechanical tolerances

1,5-5 mm +0,3 -0,3 mm

5,5-12 mm +0,6 -0,6 mm

>12 mm +0,9 -0,9 mm

BE.048.159.ST.2-MO

double P section, 4.8x15.9 mm , 2 layers of Monel wire over Silicone Tube

Round

| P/N | Diameter [mm] |

|---|---|

TE.016 |

1.6 |

TE.024 |

2.4 |

TE.032 |

3.2 |

TE.048 |

4.8 |

TE.064 |

6.4 |

TE.080 |

8.0 |

TE.095 |

9.5 |

TE.111 |

11.1 |

TE.127 |

12.7 |

TE.159 |

15.9 |

TE.191 |

19.1 |

Rectangular

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

RE.024.024 |

2.4 | 2.4 |

RE.024.048 |

2.4 | 4.8 |

RE.024.064 |

2.4 | 6.4 |

RE.032.032 |

3.2 | 3.2 |

RE.032.064 |

3.2 | 6.4 |

RE.032.080 |

3.2 | 8.0 |

RE.048.048 |

4.8 | 4.8 |

RE.048.080 |

4.8 | 8.0 |

RE.048.127 |

4.8 | 12.7 |

RE.064.064 |

6.4 | 6.4 |

RE.064.127 |

6.4 | 12.7 |

RE.080.127 |

8.0 | 12.7 |

RE.095.127 |

9.5 | 12.7 |

P section

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

PE.032.095 |

3.2 | 9.5 |

PE.032.127 |

3.2 | 12.7 |

PE.032.159 |

3.2 | 15.9 |

PE.032.191 |

3.2 | 19.1 |

PE.048.127 |

4.8 | 12.7 |

PE.048.159 |

4.8 | 15.9 |

PE.048.191 |

4.8 | 19.1 |

PE.048.222 |

4.8 | 22.2 |

PE.080.159 |

8.0 | 15.9 |

PE.080.191 |

8.0 | 19.1 |

PE.080.222 |

8.0 | 22.2 |

PE.080.254 |

8.0 | 25.4 |

PE.095.320 |

9.5 | 32.0 |

DOUBLE P section

| P/N | Height [mm] |

Width [mm] |

|---|---|---|

BE.032.095 |

3.2 | 9.5 |

BE.032.127 |

3.2 | 12.7 |

BE.032.159 |

3.2 | 15.9 |

BE.032.191 |

3.2 | 19.1 |

BE.048.159 |

4.8 | 15.9 |

BE.048.191 |

4.8 | 19.1 |

BE.048.222 |

4.8 | 22.2 |

BE.048.254 |

4.8 | 25.4 |

BE.080.191 |

8.0 | 19.1 |

BE.080.222 |

8.0 | 22.2 |

BE.080.254 |

8.0 | 25.4 |

BE.080.320 |

8.0 | 32.0 |

BE.095.320 |

9.5 | 32.0 |

Shielding performances comparison

This graph compares general performances in E-fieldand H-field screening of four gaskets made of different materials (monel, stainless steel, tinned copper and aluminium). Tests are performed on type T.064.SS.2-XX, with round cross-section and silicone sponge core, in accordance with MIL STD 285

MONEL

Material No. (DIN) 2.4360

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-MO

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 124,5 |

| 10 M | E | 107 |

| 110 M | P | 105,5 |

| 400 M | P | 98 |

| 1 G | P | 82 |

| 10 G | P | 62 |

| Magnetic | ||

| 10 K | H | 37 |

| 100 K | H | 40 |

| 1M | H | 44,5 |

Tinned Copper Clad Steel

ASTM-B-520

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-TC

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Stainless Steel

AISI 304 , Material (DIN) 1.4301

Wire Diameter 0,11 mm

Test gasket TE.064.SS.2-SL

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Aluminium

Alloy 5056 , AMS-4182

Wire Diameter 0,13 mm

Test gasket TE.064.SS.2-AL

Shielding Effectiveness

| Electrical | ||

|---|---|---|

| Frequency [Hz] | Mode | Screening [dB] |

| 1 M | E | 125,5 |

| 10 M | E | 109 |

| 110 M | P | 110 |

| 400 M | P | 99,5 |

| 1 G | P | 63 |

| 10 G | P | 58 |

| Magnetic | ||

| 10 K | H | 38 |

| 100 K | H | 62,5 |

| 1M | H | 79 |

Tests performed in accordance with MIL STD 285

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Eigenen Kommentar verfassen

Review sent

Your review cannot be sent