Sie müssen eingeloggt sein

Category

Fotos dienen nur zu Informationszwecken.

please use latin characters

|

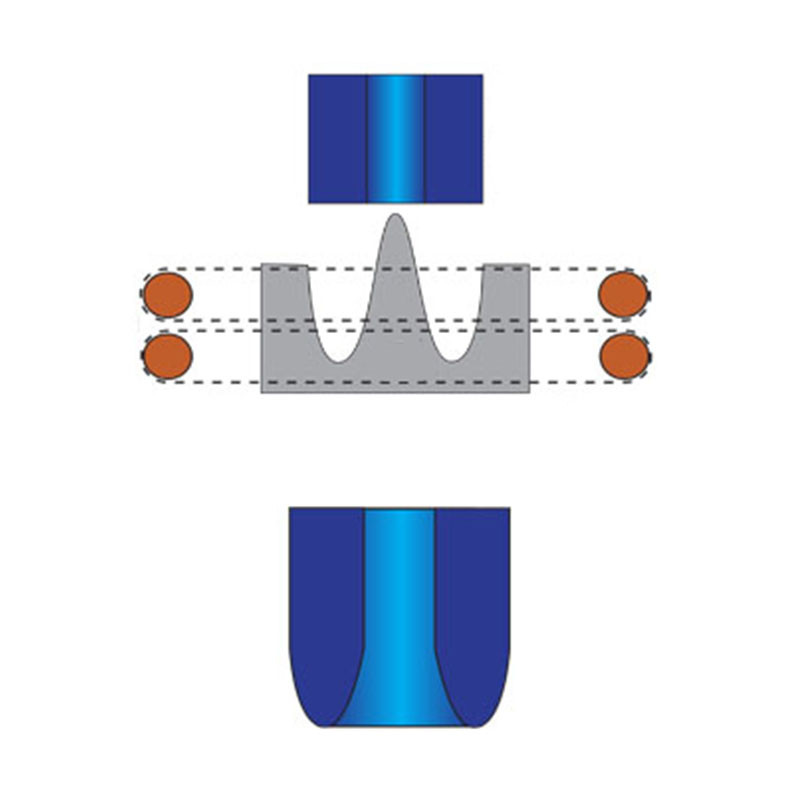

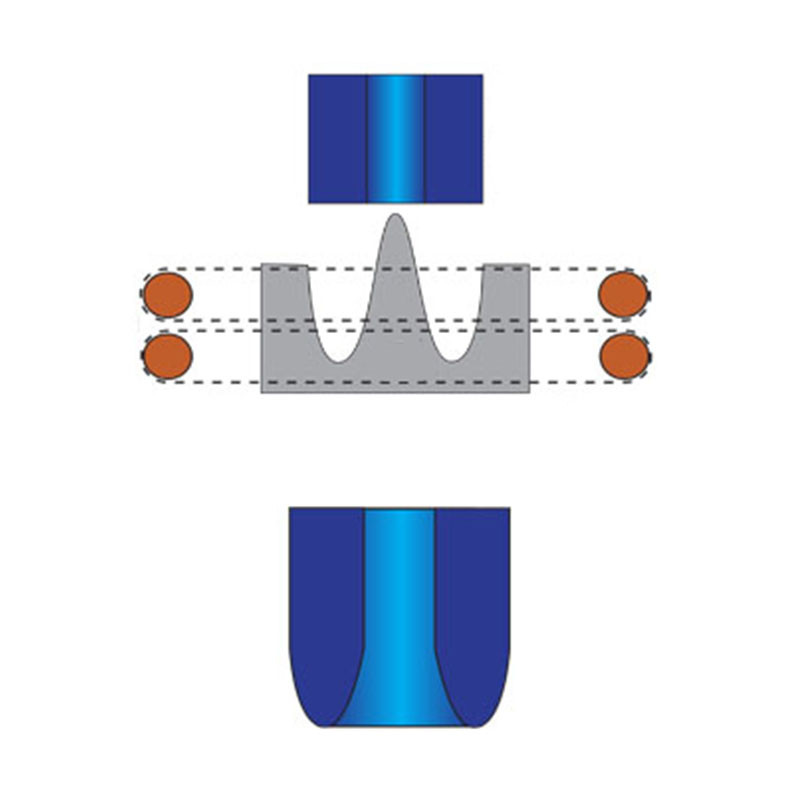

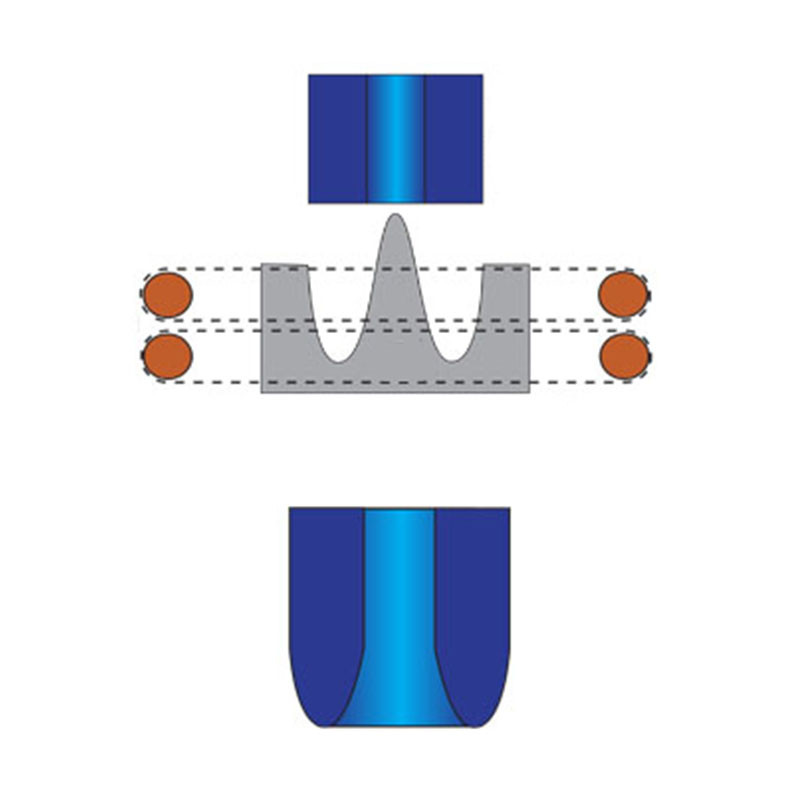

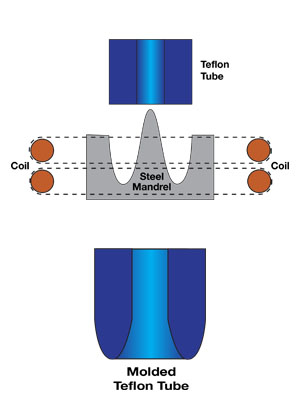

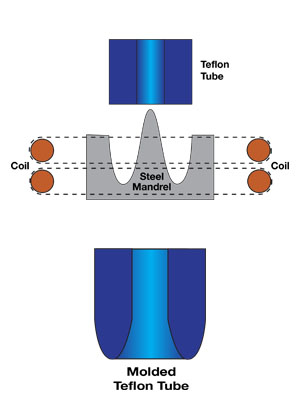

Objective: Heat a water-cooled steel mandrel to 700°F (371ºC) to form a high quality Teflon catheter tip. Material: Teflon catheter tubing, mandrel assembly Temperature: 600-700°F (315.6-371ºC) Frequency: 376 kHz Equipment:

Process: A two turn coil is used to heat the steel mandrel to 660ºF (371.1ºC) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip. Benefits:

|

|

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

|

Objective: Heat a water-cooled steel mandrel to 700°F (371ºC) to form a high quality Teflon catheter tip. Material: Teflon catheter tubing, mandrel assembly Temperature: 600-700°F (315.6-371ºC) Frequency: 376 kHz Equipment:

Process: A two turn coil is used to heat the steel mandrel to 660ºF (371.1ºC) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip. Benefits:

|

|

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Eigenen Kommentar verfassen

Review sent

Your review cannot be sent