Sie müssen eingeloggt sein

Category

Fotos dienen nur zu Informationszwecken.

please use latin characters

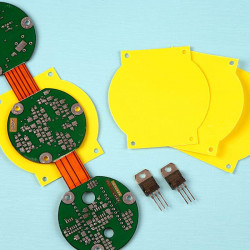

Thermal conductivity: 1.5 W / mK

produced dielectric barrier at the intersection

requires fixing with springs, metal clips or clamps

provides electrical insulation

The formula allows the reduction of air gaps on the surface

guaranteed temperature stability over a wide temperature range

any heat-generating surfaces that require thermal performance and electrical insulation

connections of power supplies with a heat sink

thermal connections of TO220 and T0241 devices with a heat sink

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test method | T-Pad 1500 | Feature (unit) | Test method | T-Pad 1500 |

| Colour | Visual | yellow | Tensile strength (N/mm) | ASTM D412 | 20 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.5 | Percentage extension (%) | ASTM D412 | 10 |

| Hardness | ASTM D2240 | 70 | Breakdown voltage (V) | ASTM D149 | >6000 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 2.9 | Resistivity | ASTM D257 | 2.0 x 1023t |

| Temperature range (°C) | - | od -40°C do +200°C | |||

| Fire Resistance | UL94 | V-0 | |||

Thermal conductivity: 6.0 W / mK

high electrical strength and thermal efficiency

unique structure allowing to reduce thermal resistance

provides electrical insulation

increased thermal efficiency

guaranteed temperature stability over a wide temperature range

any heat-generating electronic devices

connections of power supplies with a heat sink

thermal connections of TO220 and TO247 devices with a heat sink

available washers with standard thicknesses: 0.25, 0.50 and 0.75mm

sheet size 356x406mm

the offer also includes cutting out non-standard sheets

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | T-Pad 6000 | Feature (unit) | Test Method | T-Pad 6000 |

| Colour | Visual | white | Breakdown voltage (V) | ASTM D149 | >6000 |

| Thermal conductivity (W/mK) | ASTM D5470 | 6.0 | Dielectric constant (dla 1MHz) | ASTM D150 | 3.2 |

| Hardness | ASTM D2240 | 85 | resistivity(Ω cm) | ASTM D257 | 5 x 1012 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 1.10 | Degasification CVCM (%) | ASTM E595 | 0.04 |

| Temperature range (°C) | - | od -55°C do +195°C | Density (g/cm3) | - | 1.50 |

| Fire Resistance | UL94 | V-0 | |||

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | T-Pad 6500 | Feature (unit) | Test Method | T-Pad 6500 |

| Colour | Visual | light blue | Breakdown voltage (V) | ASTM D149 | >4000 |

| Thermal conductivity (W/mK) | ASTM D5470 | 6.5 | Dielectric constant (dla 1MHz) | ASTM D150 | 3.1 |

| Hardness | ASTM D2240 | 75 | resistivity (Ω cm) | ASTM D257 | 2 x 1011 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 0.95 | degassing CVCM (%) | ASTM E595 | 0.04 |

| Temperature range (°C) | - | od -40°C do +125°C | Density (g/cm3) | - | 1.46 |

| Fire Resistance | UL94 | V-0 | |||

thermal conductivity: 1.0 W / mK

good thermal performance guaranteed in the temperature range from -50oC to + 160oC

flexibility and ease of application

electrically insulated

flexible and adherent structure makes it ideal for uneven or rough surfaces

self-adhesive

cases where low costs and low thermal properties are required

systems requiring a wide temperature range

elements with an uneven surface

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniGap 1000 | Feature (unit) | Test Method | UniGap 1000 |

| Colour | Visual | Gray | Tensile strength (N/mm) | ASTM D412 | 50 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.0 | Percentage extension (%) | ASTM D412 | 61 |

| Hardness | ASTM D2240 | 45 | Breakdown voltage (V) | ASTM D149 | >27000 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 16.10 | resistivity (Ω cm) | ASTM D257 | 4 x 1023 |

| Temperature range (°C) | - | od -40°C do +150°C | degassing CVCM (%) | ASTM E595 | 0.09 |

| Fire Resistance | UL94 | V-0 | Dielectric constant (dla 1MHz) | ASTM D257 | 5.60 |

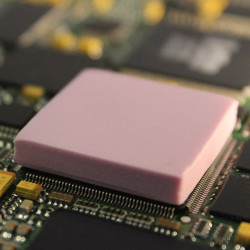

thermal conductivity: 1.7 W / mK

flexible and adherent structure makes it ideal for uneven and rough surfaces

self-adhesive

electrically insulated

made of extremely soft and flexible plastic, thanks to which it protects electronic components against damage or deformation

reduces surface thermal resistance to a minimum

easy to apply

pressure sensitive electronic components

cooling devices in rectifiers and inverters

DSP signal processors

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniGap 1700 | Feature (unit) | Test Method | UniGap 1700 |

| Colour | Visual | różowy | Percentage extension(%) | ASTM D412 | 85 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.7 | Breakdown voltage (V) | ASTM D149 | >5000 |

| Hardness | ASTM D2240 | 30 | degassing CVCM (%) | ASTM D595 | 0.08 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 1.90 | Dielectric constant (For 1MHz) | ASTM D257 | 5.0 |

| Temperature range (°C) | - | od -50°C do +200°C | |||

| Fire Resistance | UL94 | V-0 | |||

soft and adhesive gap filler with unique thermal properties

thermal conductivity 3.0W / mK

easier application due to the use of a polymer coating

exerts little pressure on an electronic device

high thermal conductivity

electrical insulation

self-adhesive

elements with an uneven surface

memory cards, VGA modules, LED packages and many more

thickness from 0.5mm to 5mm

standard sheet sizes: 229x229mm for thickness above 1mm or 457x457mm for thickness 0.5mm or 1mm

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniGap 3000 | Feature (unit) | Test Method | UniGap 3000 |

| Colour | Visual | niebieski | Tensile strength (N/mm) | ASTM D412 | 47 |

| Thermal conductivity (W/mK) | ASTM D5470 | 3.0 | Percentage extension (%) | ASTM D412 | 98 |

| Hardness | ASTM D2240 | 40 | Breakdown voltage (V) | ASTM D149 | >10000 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 4.96 | resistivity (Ω cm) | ASTM D257 | 9.5 x 1012 |

| Temperature range (°C) | - | od -50°C do +200°C | degassing CVCM (%) | ASTM E595 | 0.04 |

| Fire Resistance | UL94 | V-0 | Dielectric constant (For 1MHz) | ASTM D257 | 13.60 |

| Density (g/m3) | - | 3 | |||

thermal conductivity: 6.0 W / mK

ceramic gap filling pad

adhesive surface reducing thermal resistance

electrical insulation (ensured by high dielectric strength)

high thermal conductivity allows the removal of a large amount of heat

despite its high thermal conductivity, it still retains its softness

fills air gaps, thanks to which it increases thermal efficiency

damaged or uneven surfaces

electronic components used in the aviation, military and medical industries

unipolar transistors and other power elements as additional cooling

thickness from 0.5mm to 5mm

standard sheet size 229x229mm

Can be made with fiberglass reinforcement

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniGap 6000 | Feature (unit) | Test Method | UniGap 6000 |

| Colour | Visual | jasnoszary | Breakdown voltage (V) | ASTM D412 | >5000 |

| Thermal conductivity (W/mK) | ASTM D5470 | 6.0 | Percentage extension (%) | ASTM D412 | 20 |

| Hardness | ASTM D2240 | 70 | Breakdown voltage (V) | ASTM D149 | 6 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 3.3 | degassing CVCM (%) | ASTM E595 | 0.05 |

| Temperature range (°C) | - | od -45°C do +190°C | Dielectric constant (w 1MHz) | ASTM D257 | 3.3 |

| Fire Resistance | UL94 | HB | Density (g/m3) | - | 1.4 |

graphite, thermally conductive surface material

excellent alternative to thermal grease

maintains a constant level of thermal conductivity

great solution for elements that do not require electrical insulation

ease of application and aesthetics

thermal connection of PCB, LED etc. to the heat sink

automation, power supplies, motors and all other cases where low costs are expected

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniGap 6000 | Feature (unit) | Test Method | UniGap 6000 |

| Colour | Visual | light gray | Breakdown voltage (V) | ASTM D412 | >5000 |

| Thermal conductivity (W/mK) | ASTM D5470 | 6.0 | Percentage extension (%) | ASTM D412 | 20 |

| Hardness | ASTM D2240 | 70 | Breakdown voltage (V) | ASTM D149 | 6 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 3.3 | degassing CVCM (%) | ASTM E595 | 0.05 |

| Temperature range (°C) | - | od -45°C do +190°C | Dielectric constant (w 1MHz) | ASTM D257 | 3.3 |

| Fire Resistance | UL94 | HB | Density (g/m3) | - | 1.4 |

made in the form of a dry material covering the aluminum base

beneath the surface of the material is a thixotropic paste-like material is a good thermal connector between damaged surfaces

prevents the formation of air gaps

reduces thermal impedance

increases thermal performance

connecting electrically insulated heat emitting devices to a heat sink

power supplies and power modules

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPhase 2000 | Feature (unit) | Test Method | UniPhase 2000 |

| Thickness (mm) | - | 0.075 | Phase change temperatures (oC) | - | 60 |

| Max. Operating temperature (oC) | doświadczalna | +150 | Volume increase with phase change (%) | doświadczalna | 15% |

| Thermal impedance in 20psi(oC-cm2/W) | ASTM D5470 | 0.2 | |||

| Thermal impedance in 100psi(oC-cm2/W) | ASTM D5470 | 0.13 | |||

consists of a layer of thermally conductive material and a KaptonTM MT pad

provides high dielectric strength and resistance to mechanical damage

also works well with damaged or damaged surfaces

permanent and efficient thermal connection

reduction of thermal impedance, due to filling air gaps

application in the form of a thin strip significantly increases thermal conductivity

thermal connection of heat-generating electrical devices with a heat sink

systems where the thermal grease cannot be used

power supplies and power modules

surface materials available in rolls or sheets, aluminum washers are made to order

option of thickness selection

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPhase 2500 | Feature (unit) | Test Method | UniPhase 2500 |

| Thickness (mm) | - | 0.50 | Tensile strength during phase change (kPa) | ASTM D412 | 1.26x105 |

| Max. Operating temperature (oC) | Experimental | +150 | Volume increase with phase change (%) | doświadczalna | 15 |

| Thermal impedance in 20psi(oC-cm2/W) | ASTM D5470 | 0.45 | resistivity (Ω∙cm) | ASTM D257 | 1014 |

| Thermal conductivity (W/mK) | ASTM D5470 | 0.75 | Dielectric strength | ASTM D149 | ≤5000 |

| Phase change temperatures (oC) | - | 60 | Dielectric constant | ASTM D150 | 4.0 |

low thermal resistance

excellent operation in cooperation with even the most demanding surfaces

applied to the LED COB module, increases its service life

provides excellent thermal connection

prevents the formation of air gaps on the surface

LED COB modules

thermal connections of heat-emitting electrical devices with a heat sink

power supplies and power modules

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPhase 4000 | Feature (unit) | Test Method | UniPhase 4000 |

| Thickness (mm) | - | light gray | resistivity (Ω∙cm) | ASTM D257 | 3 x 1012 |

| Max. Operating temperature (oC) | Experimental | 6.0 | Density (g/m3) | ASTM D149 | 2.87 |

| Thermal impedance in 20psi(oC-cm2/W) | ASTM D5470 | 70 | |||

| Thermal conductivity (W/mK) | ASTM D5470 | 3.3 | |||

strongly adhesive

maintains its thermal capabilities at temperatures up to 180oC

high thermal conductivity

after application, the agent remains flexible, thanks to which it is resistant to shocks and pressure

automotive industry and telecommunications

used in power supplies and LED systems

available in tubes or containers for easy application

allows easy dosing

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPutty 1700NS | Feature (unit) | Test Method | UniPutty 1700NS |

| Colour | Visual | Gray | Dielectric strength (V/0.025mm) | ASTM D149 | 310 |

| Temperature range (oC) | - | -40oC do 180oC | Dissipation factor 25oC for 1000Hz | ASTM D150 | 0.0025 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.7 | resistivity (Ω∙cm) | ASTM D257 | 2x1015 |

| Volatile compounds at 200oC for 24 hours (%/Wt) | FTM-321 | 0 | Dielectric constant 25oC at 1000Hz | ASTM D150 | 5.0 |

| Evaporation at 200oC for 24 hours (%/Wt) | FTM-321 | 0 | |||

| Density in 25OC | ASTMD70 | 2.6 | |||

thermal conductivity 1.8W / mK

soft silicone paste with high adhesion

easy to apply

soft and tight, so it doesn't put pressure on the device

unique formula, provides excellent thermally conductive properties

Recommended for high power electronic components

LED systems and telecommunications devices

available in tubes or containers for easy application

other types of packaging are available on customer's request

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPutty 1800 | Feature (unit) | Test Method | UniPutty 1800 |

| Colour | Visual | szary | Dielectric strength (V/0.025mm) | ASTM D149 | 500 |

| Max. Operating temperature (oC) | - | -40oC do 200oC | Viscosity (mPas) | Brookfielda | od 4 mln do 8 mln |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.8 | resistivity (Ω∙cm) | ASTM D2240 | 1014 |

| Thermal resistance (oC/W) | ASTM D5470 | 1.7 | Density (g/m3) | - | 2.6 |

| degassing CVCM (%) | ASTM E595 | 0.08 | |||

silicone thermal grease with thixotropic properties

thermal conductivity 2W / mK

can be applied in room conditions, but also heated to speed up the process.

sticky and thixotropic

shock and pressure resistant

high thermal conductivity

power devices in converters and power supplies

DSP signal processors

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPutty 2000 | Feature (unit) | Test Method | UniGap 3000 |

| Colour | Visual | slate | resistivity (Ω∙cm) | ASTM D2240 | 9.15 x 1012 |

| Thermal conductivity (W/mK) | ASTM D5470 | 2.0 | Hardness | ASTM D2240 | 60 |

| Viscosity | Brookfielda | 110 000 ÷140 000 | Fire Resistance | UL94 | V-0 |

| Temperature range (oC) | - | -65oC do +200oC | |||

the basis is a thin metal foil that accelerates heat transfer between surfaces

no air gaps

non-electrically isolated connection

enables a simple and quick connection to a heat sink

high thermal conductivity

connecting power supplies or transducers to the heat sink

joining any metal surfaces

standard thickness 0.16mm

roll length 33m

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | Bondline 200 | Feature (unit) | Test Method | Bondline 200 |

| Colour | - | light gray | Inflammability | UL94 | HB |

| Thermal conductivity (W/mK) | ASTM D5470 | 0.30 | Peel strength (N/mm) | ASTM 412 | >54 |

| Thermal resistance (oC-cm2/W) | ASTM D2240 | 0.56 | Tensile strength (N/mm) | ASTM 412 | >370 |

| Working temperature (oC) | doświadczalna | -20 do +150 | Elongation (%) | ASTM 412 | 8 |

self-adhesive double-sided tape with high thermal conductivity properties

provides electrical insulation

prevents the formation of air gaps, reducing thermal resistance

high dielectric strength

very thin (0.12mm) thanks to which it shows excellent thermal properties

connecting PCBs with a heat sink

power supplies and transducers

strip thickness 0.12mm

roll length 30m, various widths available

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | Bondline 300 | Feature (unit) | Test Method | Bondline 300 |

| Clour | - | jasnobrązowy | Inflammability | UL94 | HB |

| Thermal conductivity (W/mK) | ASTM D5470 | 0.40 | Adhesion to steel (N/cm) | ASTM 412 | 3.25 |

| Thermal resistance (oC-cm2/W) | ASTM D5470 | 0.10 | Breakdown voltage (VAC) | ASTM D149 | >6000 |

| Operating temperature (oC) | Experimental | -20 do +150 | |||

thermally conductive tape, electrically insulated

allows for efficient heat flow between elements

fills air gaps, thus reducing thermal resistance

provides excellent adhesion for a wide range of materials

permanent connection of elements

high dielectric strength

simple application

connecting LED modules with a heat sink

connecting medium power components with a heat sink

standard thicknesses 0.15mm, 0.25mm, 0.5mm

roll length 30m and 50m

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | Bondline 700 | Feature (unit) | Test Method | Bondline 700 |

| Colour | - | white | Inflammability | UL94 | V2 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.1 | Breakdown voltage (V) | ASTM D149 | >6000 |

| Thermal resistance (oC-cm2/W) | ASTM D5470 | 3 | Tensile strength(kg/cm) | ASTM 412 | 0.15 |

| Operating temperature (oC) | Experimental | -25 do +130 | Elongation (%) | ASTM 412 | 400 |

provides an electrically insulated connection

prevents the formation of air gaps

offers a quick and easy connection of LED lighting with a heat sink

high thermal conductivity

joining metal surfaces

attaching the heat sink to the LED lighting

attaching the heat sink to the power supply or transducer

standard thickness 0.2mm

possibility of ordering rolls of custom sizes

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test method | Bondline 1800 | Feature (unit) | Test Method | Bondline 1800 |

| Colour | - | white | Breakdown voltage (V) | ASTM D149 | >4000 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.80 | Maximum storage length | - | 12 months |

| Thermal resistance (oC-cm2/W) | ASTM D5470 | 0.38 | |||

| Operating temperature (oC) | Experimental | -20 do +120 | |||

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | BondPutty 2000 | Feature (unit) | Test Method | BondPutty 2000 |

| Colour | - | Gray | Dielectric strength (V/mm) | ASTM D149 | >18000 |

| Temperatura pracy (oC) | - | -45o do +210 | resistivity (Ω∙cm) | ASTM D257 | 3.4 x 1013 |

| Thermal conductivity (W/mK) | ASTM D5470 | 2.0 | Percentage extension (%) | ASTM 412 | 103 |

| Hardness | ASTM D2240-95 | 50 | Tensile strength (MPa) | ASTM 412 | 2.1 |

| Viscosity (mPas) | Brookfielda | 140000 | |||

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

Thermal conductivity: 1.5 W / mK

produced dielectric barrier at the intersection

requires fixing with springs, metal clips or clamps

provides electrical insulation

The formula allows the reduction of air gaps on the surface

guaranteed temperature stability over a wide temperature range

any heat-generating surfaces that require thermal performance and electrical insulation

connections of power supplies with a heat sink

thermal connections of TO220 and T0241 devices with a heat sink

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test method | T-Pad 1500 | Feature (unit) | Test method | T-Pad 1500 |

| Colour | Visual | yellow | Tensile strength (N/mm) | ASTM D412 | 20 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.5 | Percentage extension (%) | ASTM D412 | 10 |

| Hardness | ASTM D2240 | 70 | Breakdown voltage (V) | ASTM D149 | >6000 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 2.9 | Resistivity | ASTM D257 | 2.0 x 1023t |

| Temperature range (°C) | - | od -40°C do +200°C | |||

| Fire Resistance | UL94 | V-0 | |||

Thermal conductivity: 6.0 W / mK

high electrical strength and thermal efficiency

unique structure allowing to reduce thermal resistance

provides electrical insulation

increased thermal efficiency

guaranteed temperature stability over a wide temperature range

any heat-generating electronic devices

connections of power supplies with a heat sink

thermal connections of TO220 and TO247 devices with a heat sink

available washers with standard thicknesses: 0.25, 0.50 and 0.75mm

sheet size 356x406mm

the offer also includes cutting out non-standard sheets

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | T-Pad 6000 | Feature (unit) | Test Method | T-Pad 6000 |

| Colour | Visual | white | Breakdown voltage (V) | ASTM D149 | >6000 |

| Thermal conductivity (W/mK) | ASTM D5470 | 6.0 | Dielectric constant (dla 1MHz) | ASTM D150 | 3.2 |

| Hardness | ASTM D2240 | 85 | resistivity(Ω cm) | ASTM D257 | 5 x 1012 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 1.10 | Degasification CVCM (%) | ASTM E595 | 0.04 |

| Temperature range (°C) | - | od -55°C do +195°C | Density (g/cm3) | - | 1.50 |

| Fire Resistance | UL94 | V-0 | |||

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | T-Pad 6500 | Feature (unit) | Test Method | T-Pad 6500 |

| Colour | Visual | light blue | Breakdown voltage (V) | ASTM D149 | >4000 |

| Thermal conductivity (W/mK) | ASTM D5470 | 6.5 | Dielectric constant (dla 1MHz) | ASTM D150 | 3.1 |

| Hardness | ASTM D2240 | 75 | resistivity (Ω cm) | ASTM D257 | 2 x 1011 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 0.95 | degassing CVCM (%) | ASTM E595 | 0.04 |

| Temperature range (°C) | - | od -40°C do +125°C | Density (g/cm3) | - | 1.46 |

| Fire Resistance | UL94 | V-0 | |||

thermal conductivity: 1.0 W / mK

good thermal performance guaranteed in the temperature range from -50oC to + 160oC

flexibility and ease of application

electrically insulated

flexible and adherent structure makes it ideal for uneven or rough surfaces

self-adhesive

cases where low costs and low thermal properties are required

systems requiring a wide temperature range

elements with an uneven surface

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniGap 1000 | Feature (unit) | Test Method | UniGap 1000 |

| Colour | Visual | Gray | Tensile strength (N/mm) | ASTM D412 | 50 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.0 | Percentage extension (%) | ASTM D412 | 61 |

| Hardness | ASTM D2240 | 45 | Breakdown voltage (V) | ASTM D149 | >27000 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 16.10 | resistivity (Ω cm) | ASTM D257 | 4 x 1023 |

| Temperature range (°C) | - | od -40°C do +150°C | degassing CVCM (%) | ASTM E595 | 0.09 |

| Fire Resistance | UL94 | V-0 | Dielectric constant (dla 1MHz) | ASTM D257 | 5.60 |

thermal conductivity: 1.7 W / mK

flexible and adherent structure makes it ideal for uneven and rough surfaces

self-adhesive

electrically insulated

made of extremely soft and flexible plastic, thanks to which it protects electronic components against damage or deformation

reduces surface thermal resistance to a minimum

easy to apply

pressure sensitive electronic components

cooling devices in rectifiers and inverters

DSP signal processors

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniGap 1700 | Feature (unit) | Test Method | UniGap 1700 |

| Colour | Visual | różowy | Percentage extension(%) | ASTM D412 | 85 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.7 | Breakdown voltage (V) | ASTM D149 | >5000 |

| Hardness | ASTM D2240 | 30 | degassing CVCM (%) | ASTM D595 | 0.08 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 1.90 | Dielectric constant (For 1MHz) | ASTM D257 | 5.0 |

| Temperature range (°C) | - | od -50°C do +200°C | |||

| Fire Resistance | UL94 | V-0 | |||

soft and adhesive gap filler with unique thermal properties

thermal conductivity 3.0W / mK

easier application due to the use of a polymer coating

exerts little pressure on an electronic device

high thermal conductivity

electrical insulation

self-adhesive

elements with an uneven surface

memory cards, VGA modules, LED packages and many more

thickness from 0.5mm to 5mm

standard sheet sizes: 229x229mm for thickness above 1mm or 457x457mm for thickness 0.5mm or 1mm

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniGap 3000 | Feature (unit) | Test Method | UniGap 3000 |

| Colour | Visual | niebieski | Tensile strength (N/mm) | ASTM D412 | 47 |

| Thermal conductivity (W/mK) | ASTM D5470 | 3.0 | Percentage extension (%) | ASTM D412 | 98 |

| Hardness | ASTM D2240 | 40 | Breakdown voltage (V) | ASTM D149 | >10000 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 4.96 | resistivity (Ω cm) | ASTM D257 | 9.5 x 1012 |

| Temperature range (°C) | - | od -50°C do +200°C | degassing CVCM (%) | ASTM E595 | 0.04 |

| Fire Resistance | UL94 | V-0 | Dielectric constant (For 1MHz) | ASTM D257 | 13.60 |

| Density (g/m3) | - | 3 | |||

thermal conductivity: 6.0 W / mK

ceramic gap filling pad

adhesive surface reducing thermal resistance

electrical insulation (ensured by high dielectric strength)

high thermal conductivity allows the removal of a large amount of heat

despite its high thermal conductivity, it still retains its softness

fills air gaps, thanks to which it increases thermal efficiency

damaged or uneven surfaces

electronic components used in the aviation, military and medical industries

unipolar transistors and other power elements as additional cooling

thickness from 0.5mm to 5mm

standard sheet size 229x229mm

Can be made with fiberglass reinforcement

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniGap 6000 | Feature (unit) | Test Method | UniGap 6000 |

| Colour | Visual | jasnoszary | Breakdown voltage (V) | ASTM D412 | >5000 |

| Thermal conductivity (W/mK) | ASTM D5470 | 6.0 | Percentage extension (%) | ASTM D412 | 20 |

| Hardness | ASTM D2240 | 70 | Breakdown voltage (V) | ASTM D149 | 6 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 3.3 | degassing CVCM (%) | ASTM E595 | 0.05 |

| Temperature range (°C) | - | od -45°C do +190°C | Dielectric constant (w 1MHz) | ASTM D257 | 3.3 |

| Fire Resistance | UL94 | HB | Density (g/m3) | - | 1.4 |

graphite, thermally conductive surface material

excellent alternative to thermal grease

maintains a constant level of thermal conductivity

great solution for elements that do not require electrical insulation

ease of application and aesthetics

thermal connection of PCB, LED etc. to the heat sink

automation, power supplies, motors and all other cases where low costs are expected

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniGap 6000 | Feature (unit) | Test Method | UniGap 6000 |

| Colour | Visual | light gray | Breakdown voltage (V) | ASTM D412 | >5000 |

| Thermal conductivity (W/mK) | ASTM D5470 | 6.0 | Percentage extension (%) | ASTM D412 | 20 |

| Hardness | ASTM D2240 | 70 | Breakdown voltage (V) | ASTM D149 | 6 |

| Thermal impedance (K-cm2/W w 69KPa) | ASTM D5470 | 3.3 | degassing CVCM (%) | ASTM E595 | 0.05 |

| Temperature range (°C) | - | od -45°C do +190°C | Dielectric constant (w 1MHz) | ASTM D257 | 3.3 |

| Fire Resistance | UL94 | HB | Density (g/m3) | - | 1.4 |

made in the form of a dry material covering the aluminum base

beneath the surface of the material is a thixotropic paste-like material is a good thermal connector between damaged surfaces

prevents the formation of air gaps

reduces thermal impedance

increases thermal performance

connecting electrically insulated heat emitting devices to a heat sink

power supplies and power modules

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPhase 2000 | Feature (unit) | Test Method | UniPhase 2000 |

| Thickness (mm) | - | 0.075 | Phase change temperatures (oC) | - | 60 |

| Max. Operating temperature (oC) | doświadczalna | +150 | Volume increase with phase change (%) | doświadczalna | 15% |

| Thermal impedance in 20psi(oC-cm2/W) | ASTM D5470 | 0.2 | |||

| Thermal impedance in 100psi(oC-cm2/W) | ASTM D5470 | 0.13 | |||

consists of a layer of thermally conductive material and a KaptonTM MT pad

provides high dielectric strength and resistance to mechanical damage

also works well with damaged or damaged surfaces

permanent and efficient thermal connection

reduction of thermal impedance, due to filling air gaps

application in the form of a thin strip significantly increases thermal conductivity

thermal connection of heat-generating electrical devices with a heat sink

systems where the thermal grease cannot be used

power supplies and power modules

surface materials available in rolls or sheets, aluminum washers are made to order

option of thickness selection

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPhase 2500 | Feature (unit) | Test Method | UniPhase 2500 |

| Thickness (mm) | - | 0.50 | Tensile strength during phase change (kPa) | ASTM D412 | 1.26x105 |

| Max. Operating temperature (oC) | Experimental | +150 | Volume increase with phase change (%) | doświadczalna | 15 |

| Thermal impedance in 20psi(oC-cm2/W) | ASTM D5470 | 0.45 | resistivity (Ω∙cm) | ASTM D257 | 1014 |

| Thermal conductivity (W/mK) | ASTM D5470 | 0.75 | Dielectric strength | ASTM D149 | ≤5000 |

| Phase change temperatures (oC) | - | 60 | Dielectric constant | ASTM D150 | 4.0 |

low thermal resistance

excellent operation in cooperation with even the most demanding surfaces

applied to the LED COB module, increases its service life

provides excellent thermal connection

prevents the formation of air gaps on the surface

LED COB modules

thermal connections of heat-emitting electrical devices with a heat sink

power supplies and power modules

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPhase 4000 | Feature (unit) | Test Method | UniPhase 4000 |

| Thickness (mm) | - | light gray | resistivity (Ω∙cm) | ASTM D257 | 3 x 1012 |

| Max. Operating temperature (oC) | Experimental | 6.0 | Density (g/m3) | ASTM D149 | 2.87 |

| Thermal impedance in 20psi(oC-cm2/W) | ASTM D5470 | 70 | |||

| Thermal conductivity (W/mK) | ASTM D5470 | 3.3 | |||

strongly adhesive

maintains its thermal capabilities at temperatures up to 180oC

high thermal conductivity

after application, the agent remains flexible, thanks to which it is resistant to shocks and pressure

automotive industry and telecommunications

used in power supplies and LED systems

available in tubes or containers for easy application

allows easy dosing

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPutty 1700NS | Feature (unit) | Test Method | UniPutty 1700NS |

| Colour | Visual | Gray | Dielectric strength (V/0.025mm) | ASTM D149 | 310 |

| Temperature range (oC) | - | -40oC do 180oC | Dissipation factor 25oC for 1000Hz | ASTM D150 | 0.0025 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.7 | resistivity (Ω∙cm) | ASTM D257 | 2x1015 |

| Volatile compounds at 200oC for 24 hours (%/Wt) | FTM-321 | 0 | Dielectric constant 25oC at 1000Hz | ASTM D150 | 5.0 |

| Evaporation at 200oC for 24 hours (%/Wt) | FTM-321 | 0 | |||

| Density in 25OC | ASTMD70 | 2.6 | |||

thermal conductivity 1.8W / mK

soft silicone paste with high adhesion

easy to apply

soft and tight, so it doesn't put pressure on the device

unique formula, provides excellent thermally conductive properties

Recommended for high power electronic components

LED systems and telecommunications devices

available in tubes or containers for easy application

other types of packaging are available on customer's request

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPutty 1800 | Feature (unit) | Test Method | UniPutty 1800 |

| Colour | Visual | szary | Dielectric strength (V/0.025mm) | ASTM D149 | 500 |

| Max. Operating temperature (oC) | - | -40oC do 200oC | Viscosity (mPas) | Brookfielda | od 4 mln do 8 mln |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.8 | resistivity (Ω∙cm) | ASTM D2240 | 1014 |

| Thermal resistance (oC/W) | ASTM D5470 | 1.7 | Density (g/m3) | - | 2.6 |

| degassing CVCM (%) | ASTM E595 | 0.08 | |||

silicone thermal grease with thixotropic properties

thermal conductivity 2W / mK

can be applied in room conditions, but also heated to speed up the process.

sticky and thixotropic

shock and pressure resistant

high thermal conductivity

power devices in converters and power supplies

DSP signal processors

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | UniPutty 2000 | Feature (unit) | Test Method | UniGap 3000 |

| Colour | Visual | slate | resistivity (Ω∙cm) | ASTM D2240 | 9.15 x 1012 |

| Thermal conductivity (W/mK) | ASTM D5470 | 2.0 | Hardness | ASTM D2240 | 60 |

| Viscosity | Brookfielda | 110 000 ÷140 000 | Fire Resistance | UL94 | V-0 |

| Temperature range (oC) | - | -65oC do +200oC | |||

the basis is a thin metal foil that accelerates heat transfer between surfaces

no air gaps

non-electrically isolated connection

enables a simple and quick connection to a heat sink

high thermal conductivity

connecting power supplies or transducers to the heat sink

joining any metal surfaces

standard thickness 0.16mm

roll length 33m

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | Bondline 200 | Feature (unit) | Test Method | Bondline 200 |

| Colour | - | light gray | Inflammability | UL94 | HB |

| Thermal conductivity (W/mK) | ASTM D5470 | 0.30 | Peel strength (N/mm) | ASTM 412 | >54 |

| Thermal resistance (oC-cm2/W) | ASTM D2240 | 0.56 | Tensile strength (N/mm) | ASTM 412 | >370 |

| Working temperature (oC) | doświadczalna | -20 do +150 | Elongation (%) | ASTM 412 | 8 |

self-adhesive double-sided tape with high thermal conductivity properties

provides electrical insulation

prevents the formation of air gaps, reducing thermal resistance

high dielectric strength

very thin (0.12mm) thanks to which it shows excellent thermal properties

connecting PCBs with a heat sink

power supplies and transducers

strip thickness 0.12mm

roll length 30m, various widths available

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | Bondline 300 | Feature (unit) | Test Method | Bondline 300 |

| Clour | - | jasnobrązowy | Inflammability | UL94 | HB |

| Thermal conductivity (W/mK) | ASTM D5470 | 0.40 | Adhesion to steel (N/cm) | ASTM 412 | 3.25 |

| Thermal resistance (oC-cm2/W) | ASTM D5470 | 0.10 | Breakdown voltage (VAC) | ASTM D149 | >6000 |

| Operating temperature (oC) | Experimental | -20 do +150 | |||

thermally conductive tape, electrically insulated

allows for efficient heat flow between elements

fills air gaps, thus reducing thermal resistance

provides excellent adhesion for a wide range of materials

permanent connection of elements

high dielectric strength

simple application

connecting LED modules with a heat sink

connecting medium power components with a heat sink

standard thicknesses 0.15mm, 0.25mm, 0.5mm

roll length 30m and 50m

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | Bondline 700 | Feature (unit) | Test Method | Bondline 700 |

| Colour | - | white | Inflammability | UL94 | V2 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.1 | Breakdown voltage (V) | ASTM D149 | >6000 |

| Thermal resistance (oC-cm2/W) | ASTM D5470 | 3 | Tensile strength(kg/cm) | ASTM 412 | 0.15 |

| Operating temperature (oC) | Experimental | -25 do +130 | Elongation (%) | ASTM 412 | 400 |

provides an electrically insulated connection

prevents the formation of air gaps

offers a quick and easy connection of LED lighting with a heat sink

high thermal conductivity

joining metal surfaces

attaching the heat sink to the LED lighting

attaching the heat sink to the power supply or transducer

standard thickness 0.2mm

possibility of ordering rolls of custom sizes

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test method | Bondline 1800 | Feature (unit) | Test Method | Bondline 1800 |

| Colour | - | white | Breakdown voltage (V) | ASTM D149 | >4000 |

| Thermal conductivity (W/mK) | ASTM D5470 | 1.80 | Maximum storage length | - | 12 months |

| Thermal resistance (oC-cm2/W) | ASTM D5470 | 0.38 | |||

| Operating temperature (oC) | Experimental | -20 do +120 | |||

| Physical properties | Electrical and mechanical properties | ||||

|---|---|---|---|---|---|

| Feature (unit) | Test Method | BondPutty 2000 | Feature (unit) | Test Method | BondPutty 2000 |

| Colour | - | Gray | Dielectric strength (V/mm) | ASTM D149 | >18000 |

| Temperatura pracy (oC) | - | -45o do +210 | resistivity (Ω∙cm) | ASTM D257 | 3.4 x 1013 |

| Thermal conductivity (W/mK) | ASTM D5470 | 2.0 | Percentage extension (%) | ASTM 412 | 103 |

| Hardness | ASTM D2240-95 | 50 | Tensile strength (MPa) | ASTM 412 | 2.1 |

| Viscosity (mPas) | Brookfielda | 140000 | |||

Ihre Bewertung der Rezension kann nicht gesendet werden

Kommentar melden

Meldung gesendet

Ihre Meldung kann nicht gesendet werden

Eigenen Kommentar verfassen

Bewertung gesendet

Ihre Bewertung kann nicht gesendet werden