-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

-

Recorders

- Hybrid Recorders - AL3000 Series | CHINO

- Graphic Recorder - KR2000 Series | CHINO

- Ubiquitous Recorders - KR5000 Series | CHINO

- Palm-sized Temperature/Humidity Meters - HN-CH Series | CHINO

- Consumables for Recorders

- 71VR1 - Compact Paperless Recorder | M-SYSTEM

- Graphic Recorder - KR3000 Series | CHINO

- PC Recorders - R1M Series | M-SYSTEM

- PC Recorders - R2M Series | M-SYSTEM

- PC Recorders - RZMS Series | M-SYSTEM

- PC Recorders - RZUS Series | M-SYSTEM

- Go to the subcategory

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- Galvanized and Stainless Steel Cylindrical Braids

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Hoses

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Photos are for informational purposes only. View product specification

please use latin characters

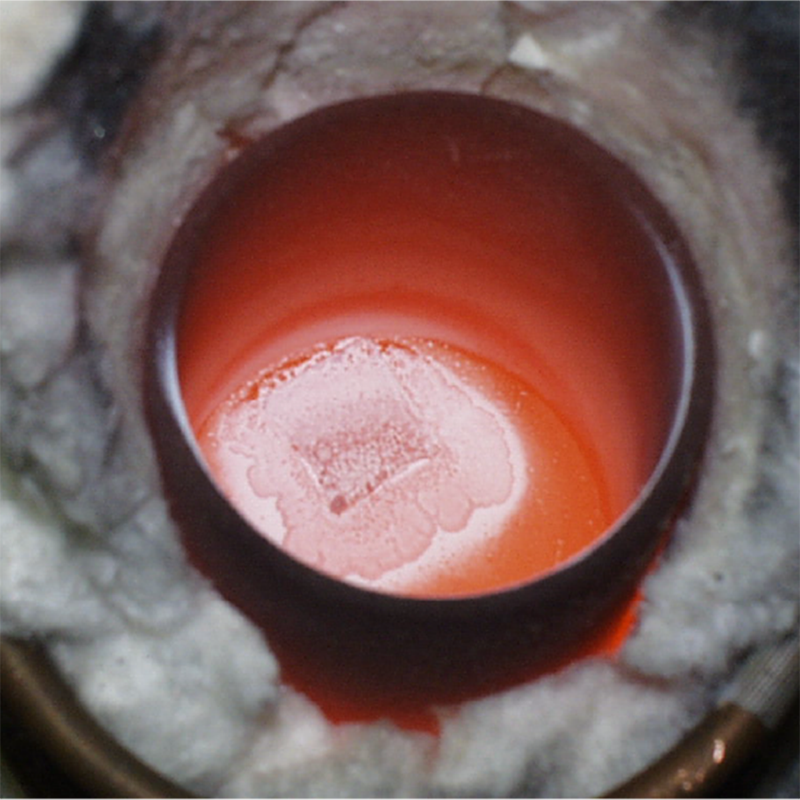

Melting silicon in graphite crucible for material testing

Objective: Melting ~ 2.1 oz (0.7g) silicon for a material testing application.

Equipment:

- Ambrell EASYHEAT 6 kW induction heating system, equipped with a remote workhead containing two 1.0 μF capacitors for a total of 0.5 μF.

- An induction heating coil designed and developed specifically for this application.

Frequency: 196 kHz

Material:

- ~ 2.1 oz (0.7g) silicon,

- graphite crucible 2.03” (51.6mm) OD, 1.02” (25.9mm) high with a wall thickness of .125” (3.2mm), insulation

Temperature: 2552 ºF (1400 ºC)

Testing:

- A four turn helical coil is used to heat the crucible. The crucible is wrapped with a layer of insulation and placed into the coil. Power is applied and the crucible reaches the required 2552 ºF (1400 ºC) in 1 minute and 12 seconds.

The customer is developing a university lab experiment to melt silicon and is still developing the process. Ameritherm equipment was recommended for the process by fellow coworkers that previously used Ameritherm equipment. Ameritherm’s Scottsville lab proved the silicon can be melted in a graphite crucible and the melt temperature can be easily controlled using a temperature controller to control the power supply. The small remote workhead with the EASYHEAT 6 kW makes the system set up appropriate for a laboratory environment.

Benefits:

- Fast, controllable and accurate heat.

- Repeatable results.

- Even distribution of heating.

Send an inquiry

Are you interested in this product? Do you need additional information or individual pricing?

Contact us

Melting silicon in graphite crucible for material testing

Objective: Melting ~ 2.1 oz (0.7g) silicon for a material testing application.

Equipment:

- Ambrell EASYHEAT 6 kW induction heating system, equipped with a remote workhead containing two 1.0 μF capacitors for a total of 0.5 μF.

- An induction heating coil designed and developed specifically for this application.

Frequency: 196 kHz

Material:

- ~ 2.1 oz (0.7g) silicon,

- graphite crucible 2.03” (51.6mm) OD, 1.02” (25.9mm) high with a wall thickness of .125” (3.2mm), insulation

Temperature: 2552 ºF (1400 ºC)

Testing:

- A four turn helical coil is used to heat the crucible. The crucible is wrapped with a layer of insulation and placed into the coil. Power is applied and the crucible reaches the required 2552 ºF (1400 ºC) in 1 minute and 12 seconds.

The customer is developing a university lab experiment to melt silicon and is still developing the process. Ameritherm equipment was recommended for the process by fellow coworkers that previously used Ameritherm equipment. Ameritherm’s Scottsville lab proved the silicon can be melted in a graphite crucible and the melt temperature can be easily controlled using a temperature controller to control the power supply. The small remote workhead with the EASYHEAT 6 kW makes the system set up appropriate for a laboratory environment.

Benefits:

- Fast, controllable and accurate heat.

- Repeatable results.

- Even distribution of heating.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent