Category

Photos are for informational purposes only. View product specification

please use latin characters

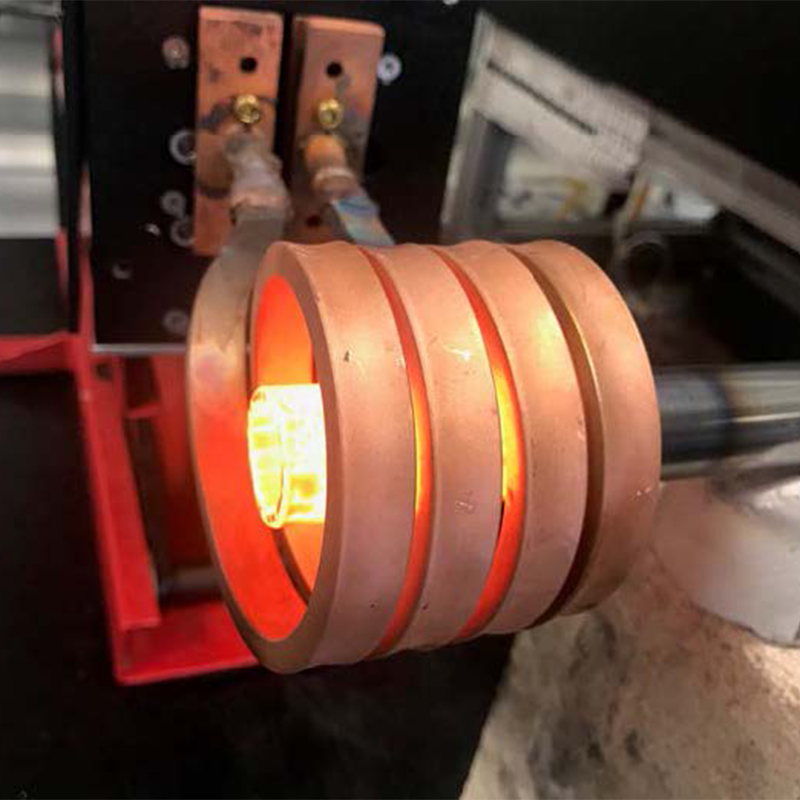

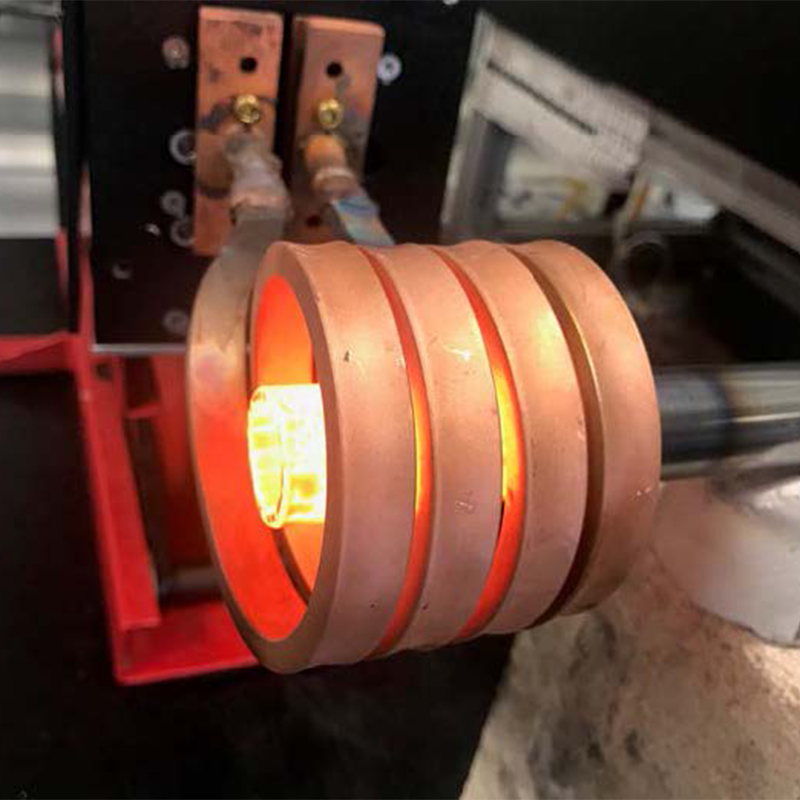

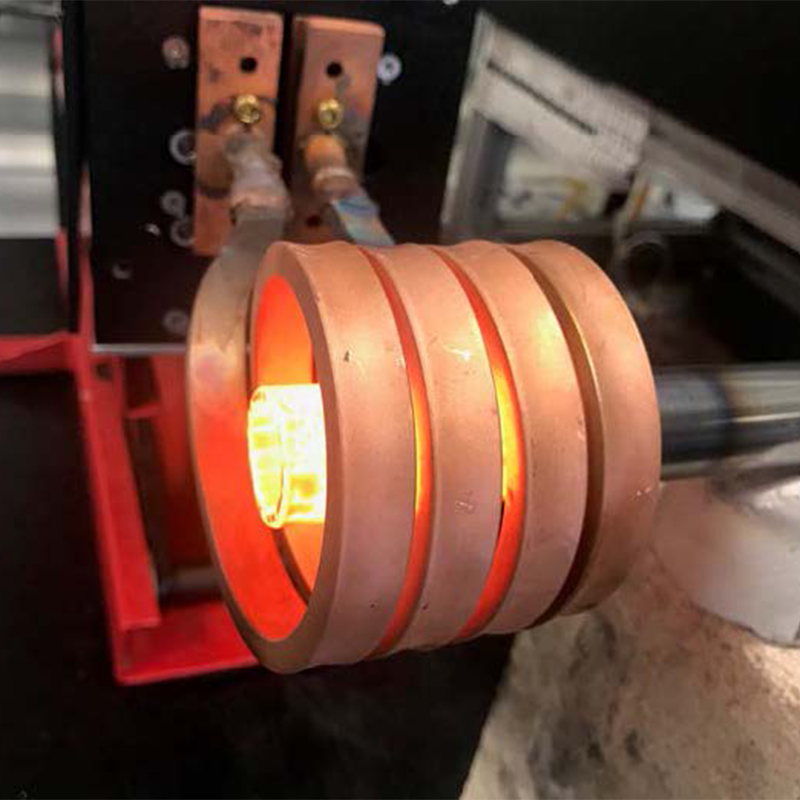

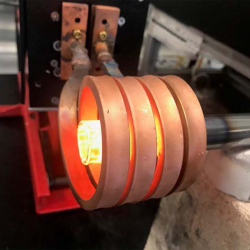

Objective: To heat steel tube ends for a flattening/bending applications; the end customer uses products in the manufacturing industry.

Frequency: 191 kHz

Material: Steel tubes

Temperature: 1600 ºF (871 ºC)

Process: First, temperature indicating paint was applied to the part, which dissolves when the part reaches the target temperature. It took less than 20 seconds to heat the provided smaller tube sample to 1600 °F (871 °C) and it took 40 seconds to heat the larger sample tube to temperature. The client was seeing heating times of at least two minutes with an oven, so this is a significant improvement.

Benefits:

Are you interested in this product? Do you need additional information or individual pricing?

Objective: To heat steel tube ends for a flattening/bending applications; the end customer uses products in the manufacturing industry.

Frequency: 191 kHz

Material: Steel tubes

Temperature: 1600 ºF (871 ºC)

Process: First, temperature indicating paint was applied to the part, which dissolves when the part reaches the target temperature. It took less than 20 seconds to heat the provided smaller tube sample to 1600 °F (871 °C) and it took 40 seconds to heat the larger sample tube to temperature. The client was seeing heating times of at least two minutes with an oven, so this is a significant improvement.

Benefits:

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent