Category

Photos are for informational purposes only. View product specification

please use latin characters

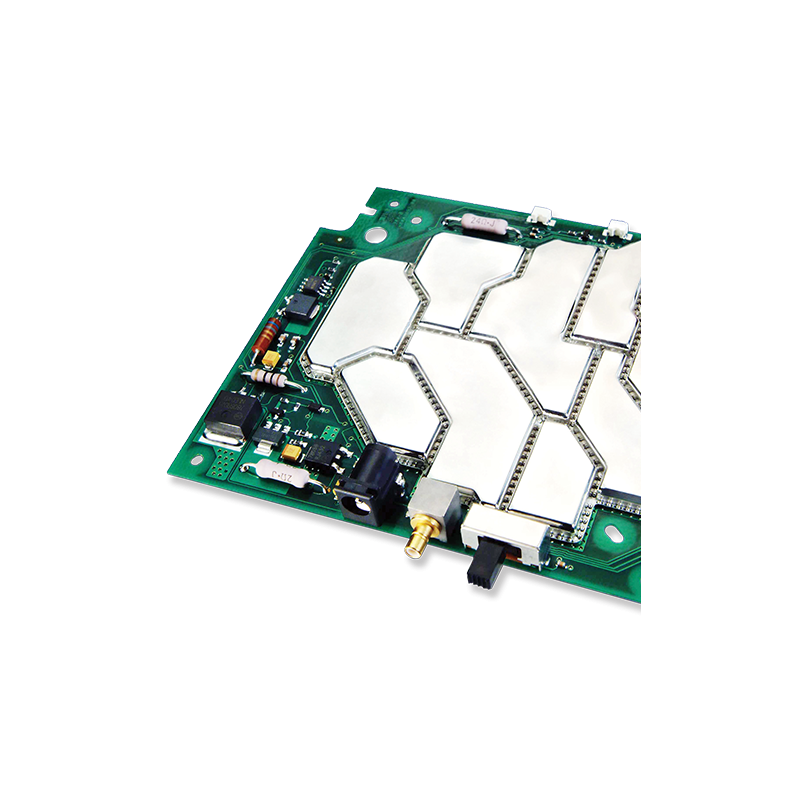

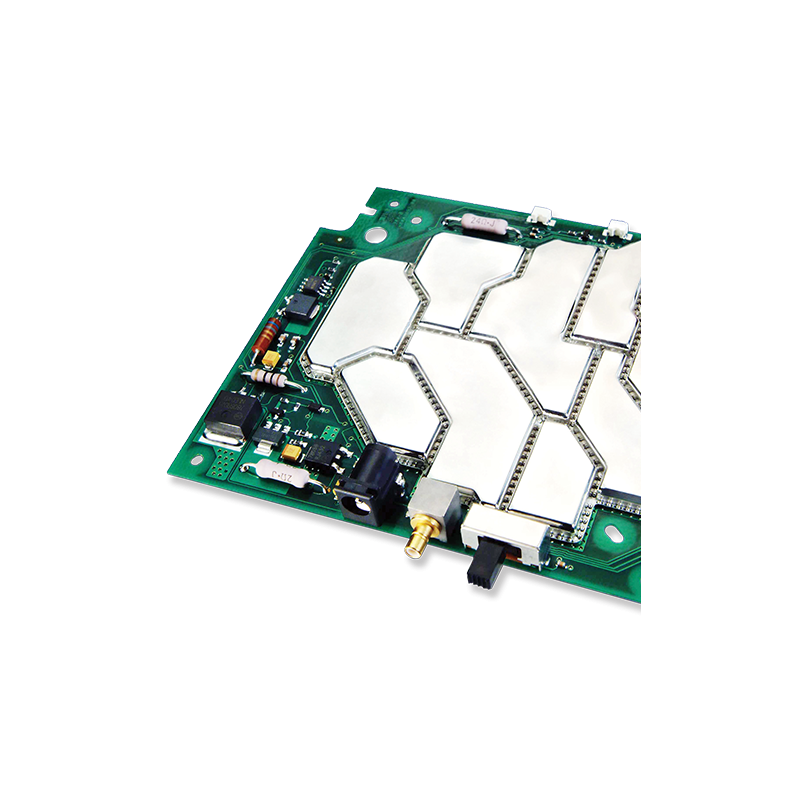

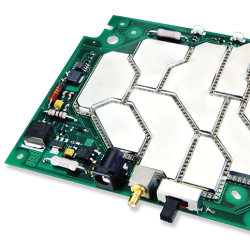

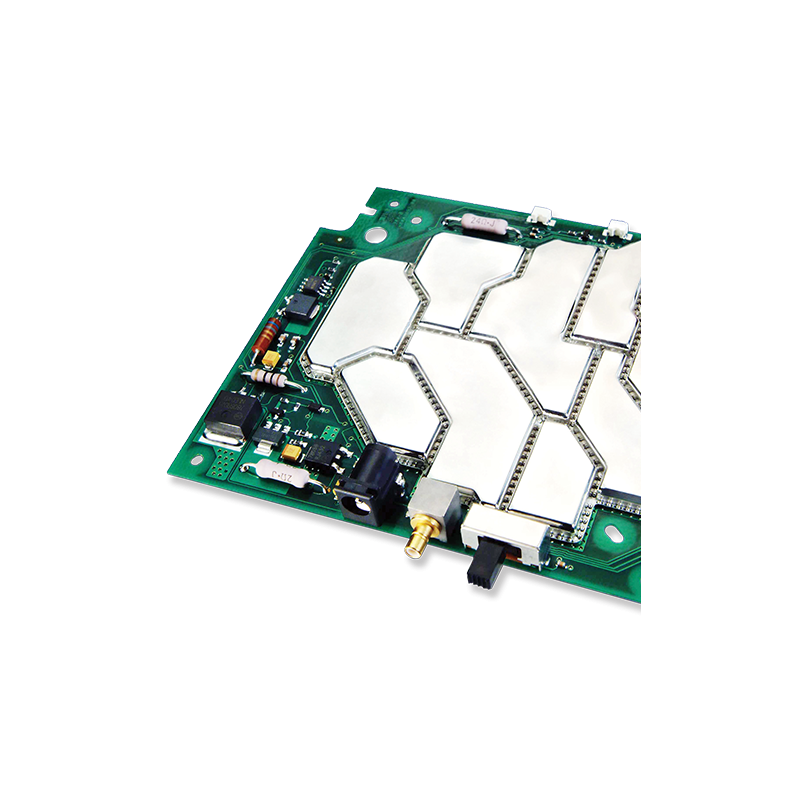

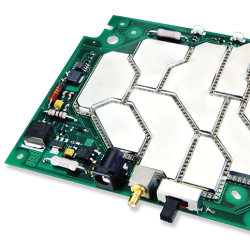

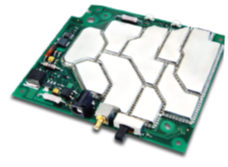

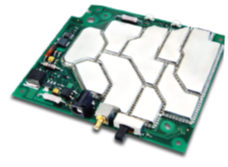

SnapShot® EMI shielding enclosures are revolutionary single- or multi-compartment shields that address many challenges associated with existing shielding technologies. The lightweight, metallized plastic material is thermoformed into virtually any design and offers excellent shielding performance compared to perforated or metal cans with a frame and cover.

SnapShot features an excellent design. It is a lightweight metallized plastic with a revolutionary “snap-in-place” system. Metallized plastic:

• Conductive outer surface (tin)

• Non-conductive inner surface (PEI)

Polyetherimide

Tin Coating

Snap-in mounting on solder balls:

• Manual or automated soldering using installation tools

• Creates a strong electromechanical connection

| Material Properties | Value | Method |

|---|---|---|

| Thickness | 0.125 mm | – |

| Shielding Effectiveness | 75 dB | ASTM D4935 |

| Surface Resistance | 0.025 Ohms/square | ASTM F390 |

| Metallization Adhesion | 5B | ASTM D3359 |

| Metallization Thickness | 5 Microns | SEM |

| Dielectric Strength | 80 kV/mm | ASTM D149 |

| Vicat Softening Temperature B | 215°C | ASTM D1525 |

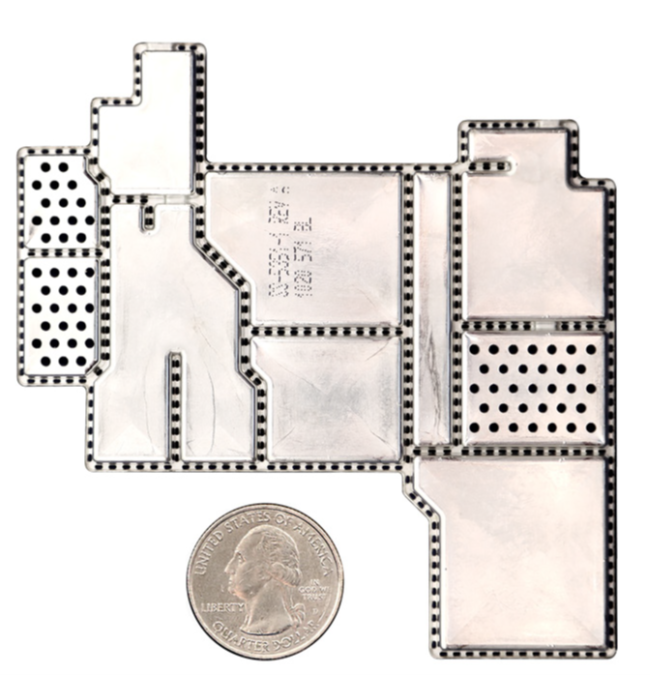

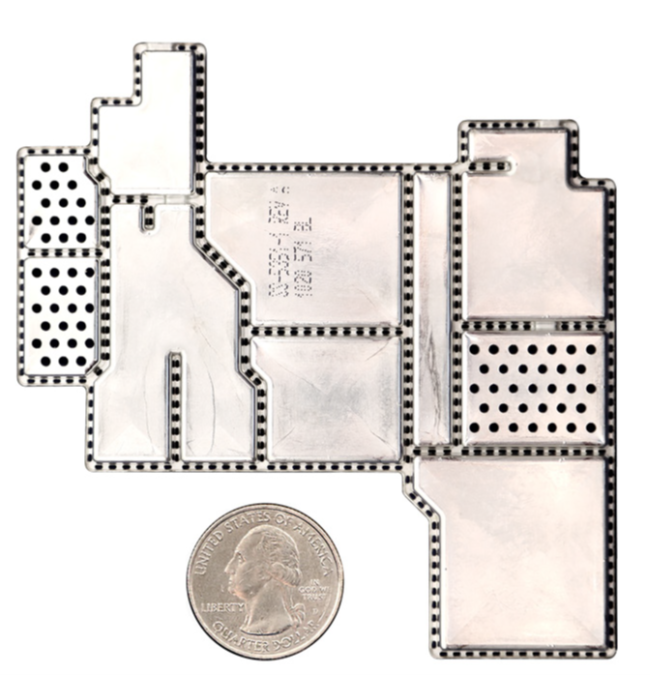

Each application is custom-made to meet unique size and shape requirements of the shielding enclosure layout.

PCB shields are thermoformed into virtually any shape:

• The shield can have multiple compartments in one configuration

• Different PCB shield heights are possible within one configuration

• Low profile with virtually zero clearance between components and the inner shield surface

• With or without surface perforations

• Excellent shielding capability for edge connectors

SnapShot shielding enclosures have undergone shock, vibration, humidity, and aging tests, making SnapShot EMC shields ideal for industrial and military electronics:

• Mechanical Shock (OEDEC JESD 22-B104-B)

• Impact (IEC 60668-2-29)

• Vibration (IEC 60068-2-64)

• Thermal Shock (MIL-STD-883CA)

• Dry Thermal Aging

• Humid Heat Aging

Easy installation after reflow allows free inspection and rework.

| Allows manual removal and replacement without damaging the board and without the need for re-soldering.

| Simple BGA attachment mechanism using solder balls as individual mechanical snaps.

| Enables automated optical inspection.

Perfect for weight-sensitive applications. The specialized thermoplastic material is extremely lightweight. The thin, non-ferrous polymer is tin-metallized on the outer surface.

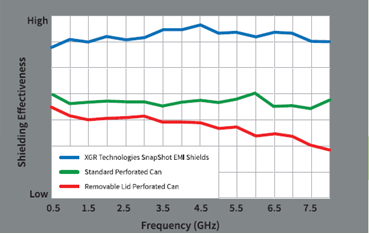

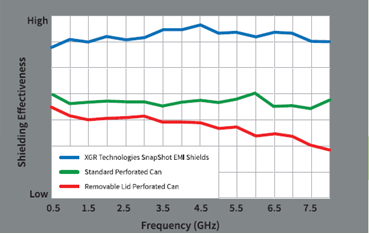

SnapShot® outperforms competitive options in shielding effectiveness from below 1 GHz to 12 GHz. Extremely consistent isolation across a wide frequency range. The non-conductive inner surface reduces electromagnetic coupling with circuit traces, minimizes total volume, and eliminates short-circuit risk.

Relative Shielding Effectiveness of XGR SnapShot EMI Shields Compared to Traditional Metal Cans (10 dB per section)

SnapShot shielding solder balls are supplied in tape-and-reel packaging. These solder balls can be used on standard SMT equipment and are RoHS and REACH compliant.

| Specification | Data |

|---|---|

| P/N Code | 10184670 |

| Composition | 96.5Sn/3.5Ag |

| Dimension | 0.035" (0.889mm) |

| Tolerance | +/0.0015" (0.038mm) |

| Pieces/Reel | 20,000 |

Are you interested in this product? Do you need additional information or individual pricing?

SnapShot® EMI shielding enclosures are revolutionary single- or multi-compartment shields that address many challenges associated with existing shielding technologies. The lightweight, metallized plastic material is thermoformed into virtually any design and offers excellent shielding performance compared to perforated or metal cans with a frame and cover.

SnapShot features an excellent design. It is a lightweight metallized plastic with a revolutionary “snap-in-place” system. Metallized plastic:

• Conductive outer surface (tin)

• Non-conductive inner surface (PEI)

Polyetherimide

Tin Coating

Snap-in mounting on solder balls:

• Manual or automated soldering using installation tools

• Creates a strong electromechanical connection

| Material Properties | Value | Method |

|---|---|---|

| Thickness | 0.125 mm | – |

| Shielding Effectiveness | 75 dB | ASTM D4935 |

| Surface Resistance | 0.025 Ohms/square | ASTM F390 |

| Metallization Adhesion | 5B | ASTM D3359 |

| Metallization Thickness | 5 Microns | SEM |

| Dielectric Strength | 80 kV/mm | ASTM D149 |

| Vicat Softening Temperature B | 215°C | ASTM D1525 |

Each application is custom-made to meet unique size and shape requirements of the shielding enclosure layout.

PCB shields are thermoformed into virtually any shape:

• The shield can have multiple compartments in one configuration

• Different PCB shield heights are possible within one configuration

• Low profile with virtually zero clearance between components and the inner shield surface

• With or without surface perforations

• Excellent shielding capability for edge connectors

SnapShot shielding enclosures have undergone shock, vibration, humidity, and aging tests, making SnapShot EMC shields ideal for industrial and military electronics:

• Mechanical Shock (OEDEC JESD 22-B104-B)

• Impact (IEC 60668-2-29)

• Vibration (IEC 60068-2-64)

• Thermal Shock (MIL-STD-883CA)

• Dry Thermal Aging

• Humid Heat Aging

Easy installation after reflow allows free inspection and rework.

| Allows manual removal and replacement without damaging the board and without the need for re-soldering.

| Simple BGA attachment mechanism using solder balls as individual mechanical snaps.

| Enables automated optical inspection.

Perfect for weight-sensitive applications. The specialized thermoplastic material is extremely lightweight. The thin, non-ferrous polymer is tin-metallized on the outer surface.

SnapShot® outperforms competitive options in shielding effectiveness from below 1 GHz to 12 GHz. Extremely consistent isolation across a wide frequency range. The non-conductive inner surface reduces electromagnetic coupling with circuit traces, minimizes total volume, and eliminates short-circuit risk.

Relative Shielding Effectiveness of XGR SnapShot EMI Shields Compared to Traditional Metal Cans (10 dB per section)

SnapShot shielding solder balls are supplied in tape-and-reel packaging. These solder balls can be used on standard SMT equipment and are RoHS and REACH compliant.

| Specification | Data |

|---|---|

| P/N Code | 10184670 |

| Composition | 96.5Sn/3.5Ag |

| Dimension | 0.035" (0.889mm) |

| Tolerance | +/0.0015" (0.038mm) |

| Pieces/Reel | 20,000 |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent