Category

Photos are for informational purposes only. View product specification

please use latin characters

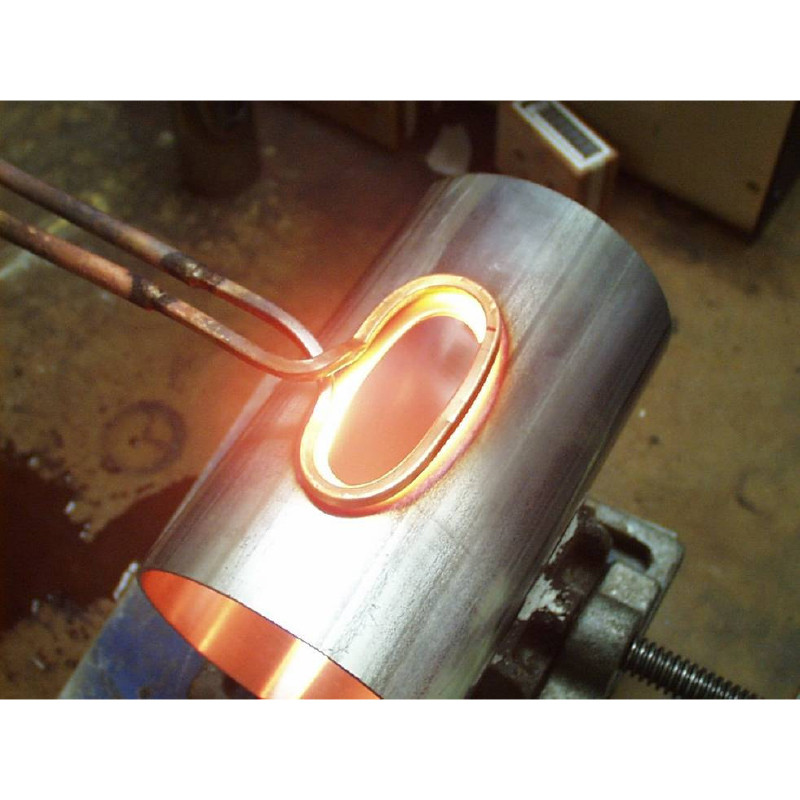

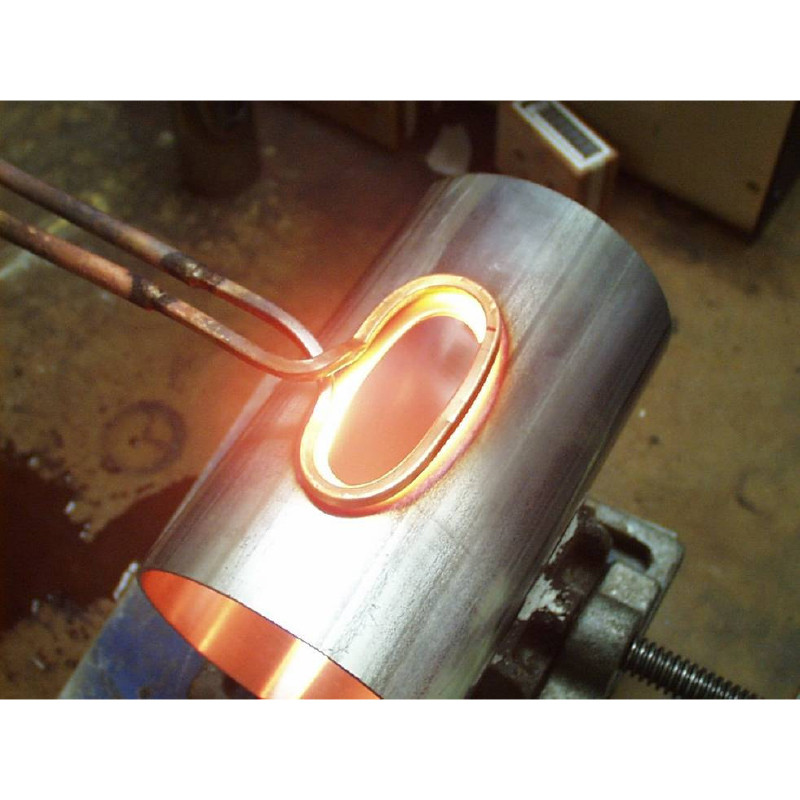

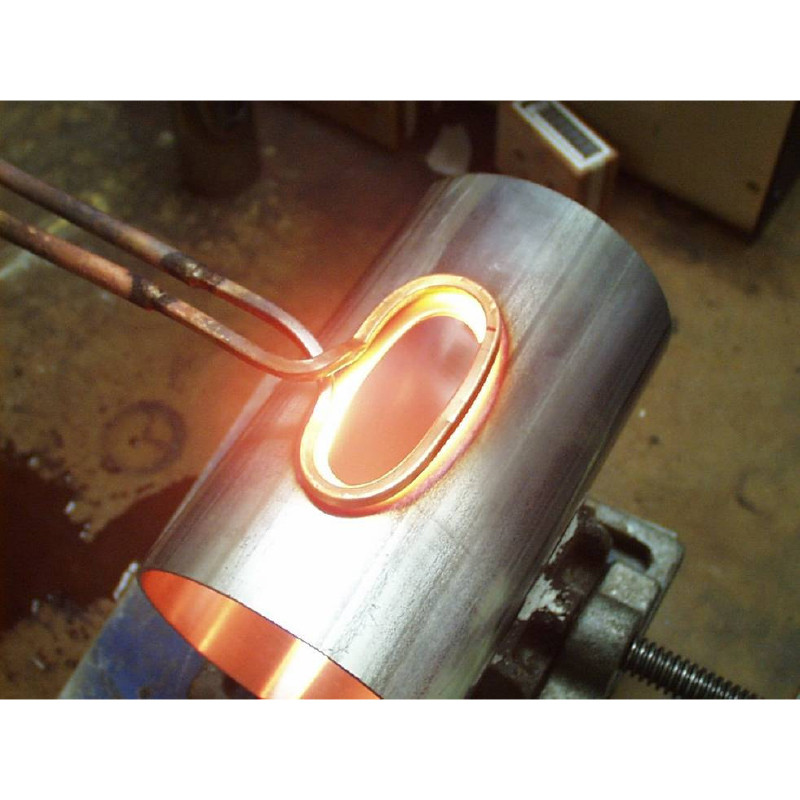

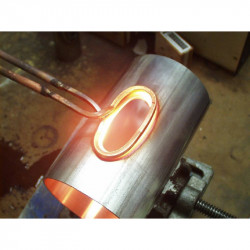

Objective: To anneal a ¼” area around an oval cutout on a stainless steel tube prior to extrusion.

Frequency: 300 kHz

Material: .75” (19mm), 1.5” (38.1mm) and 4” (101.6mm) diameter steel tubes

Temperature: 1900 °F (1038 °C)

A single turn helical coil is used on the 4” (101.6mm) diameter tubes and a two turn helical coil is used on the smaller diameters. The coil is placed over the oval cutout and power is supplied for 15 seconds to anneal a 0.25" (6.35mm) diameter around the cutout.

Are you interested in this product? Do you need additional information or individual pricing?

Objective: To anneal a ¼” area around an oval cutout on a stainless steel tube prior to extrusion.

Frequency: 300 kHz

Material: .75” (19mm), 1.5” (38.1mm) and 4” (101.6mm) diameter steel tubes

Temperature: 1900 °F (1038 °C)

A single turn helical coil is used on the 4” (101.6mm) diameter tubes and a two turn helical coil is used on the smaller diameters. The coil is placed over the oval cutout and power is supplied for 15 seconds to anneal a 0.25" (6.35mm) diameter around the cutout.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent