Category

Photos are for informational purposes only. View product specification

please use latin characters

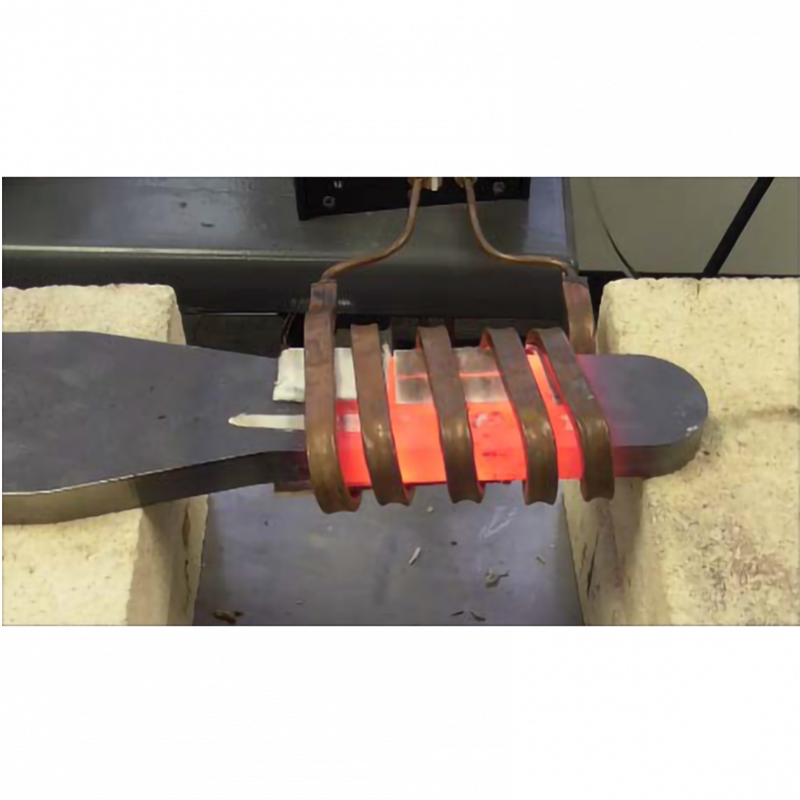

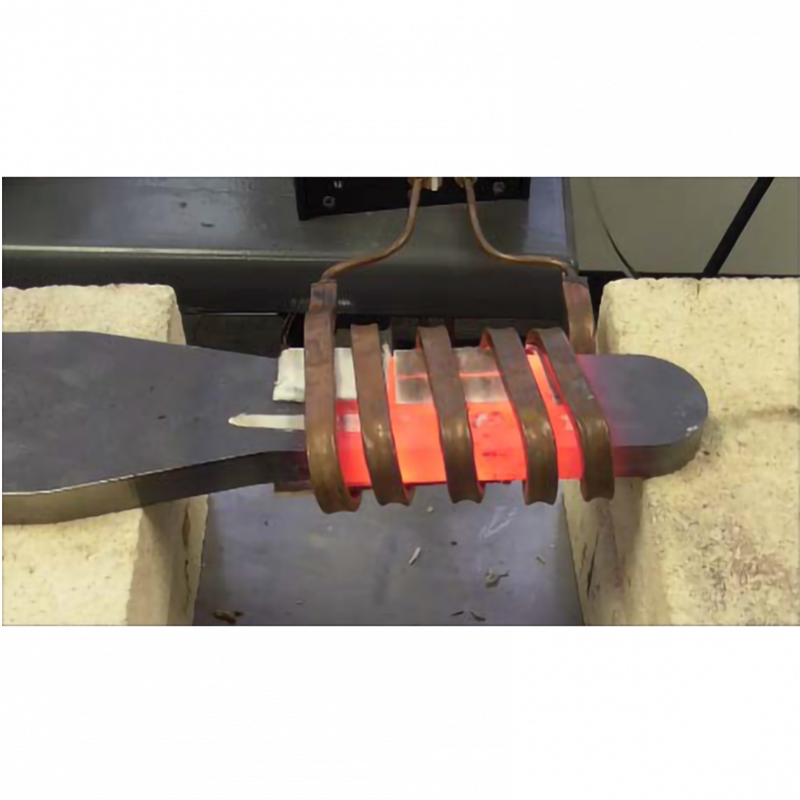

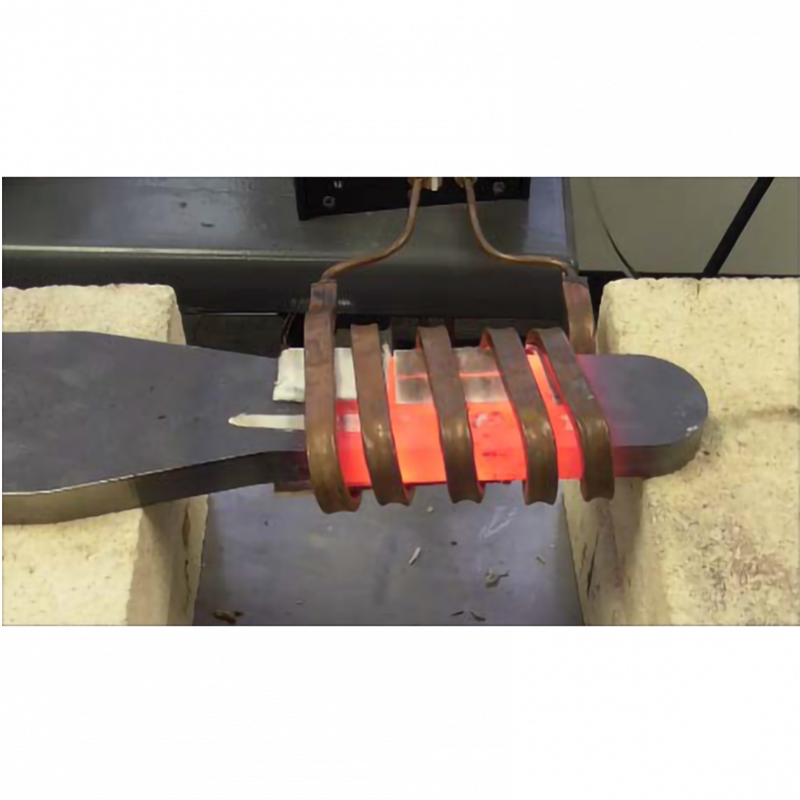

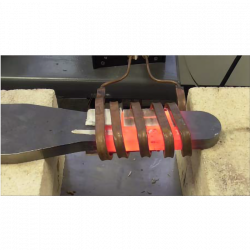

Objective: To heat a magnetic steel part for a forming application; the client had been using a torch for the application.

Frequency: 125 kHz

Material: Magnetic steel part

Temperature: 1700 °F (927 °C)

Temperature indicating paint was applied to the part to easily identify when it achieved temperature, and then the induction power was turned on. It took about three minutes for the part to reach 1700 °F (927 °C) at 10 kW and two minutes and twenty seconds with 15 kW for this through-Curie heating application.

Are you interested in this product? Do you need additional information or individual pricing?

Objective: To heat a magnetic steel part for a forming application; the client had been using a torch for the application.

Frequency: 125 kHz

Material: Magnetic steel part

Temperature: 1700 °F (927 °C)

Temperature indicating paint was applied to the part to easily identify when it achieved temperature, and then the induction power was turned on. It took about three minutes for the part to reach 1700 °F (927 °C) at 10 kW and two minutes and twenty seconds with 15 kW for this through-Curie heating application.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent