Category

Photos are for informational purposes only. View product specification

please use latin characters

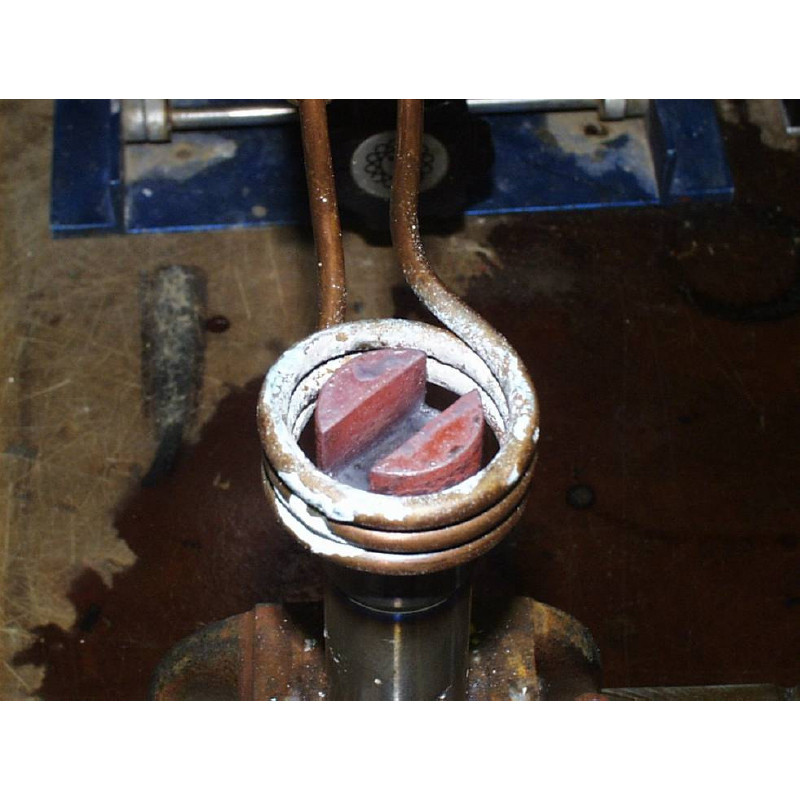

Objective: Annealing the end of a steel hydraulic motor shaft prior to machining.

Frequency: 259 kHz

Material: 0.75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end.

Temperature: 1350 °F (732 °C)

A three turn helical coil is used for annealing the motor shaft. The end of the motor shaft is placed in the coil and power is applied for 20 seconds to reach 1350 ºF (732 ºC) and turn the steel red hot.

Are you interested in this product? Do you need additional information or individual pricing?

Objective: Annealing the end of a steel hydraulic motor shaft prior to machining.

Frequency: 259 kHz

Material: 0.75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end.

Temperature: 1350 °F (732 °C)

A three turn helical coil is used for annealing the motor shaft. The end of the motor shaft is placed in the coil and power is applied for 20 seconds to reach 1350 ºF (732 ºC) and turn the steel red hot.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent