Category

Photos are for informational purposes only. View product specification

please use latin characters

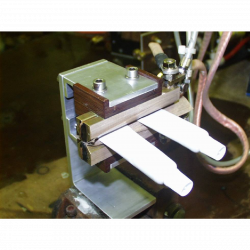

Objective: Melting the end pieces of a plastic tube together to create an air tight seal.

Frequency: 185 kHz

Material: Plastic tube 2.5” (63.5mm) long, 0.75” (19mm) diameter.

A single turn coil encapsulated in custom blocks is used for sealing the tube. Two tubes are placed between the coil blocks and a 7lb (3.2kg) load is applied to the top of the coil. Power is only supplied to the top block of the coil for 250 milli-seconds causing the plastic to melt and create an air tight seal.

Are you interested in this product? Do you need additional information or individual pricing?

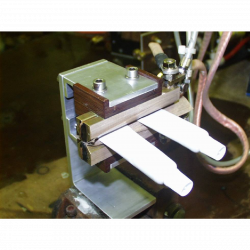

Objective: Melting the end pieces of a plastic tube together to create an air tight seal.

Frequency: 185 kHz

Material: Plastic tube 2.5” (63.5mm) long, 0.75” (19mm) diameter.

A single turn coil encapsulated in custom blocks is used for sealing the tube. Two tubes are placed between the coil blocks and a 7lb (3.2kg) load is applied to the top of the coil. Power is only supplied to the top block of the coil for 250 milli-seconds causing the plastic to melt and create an air tight seal.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent