Category

Photos are for informational purposes only. View product specification

please use latin characters

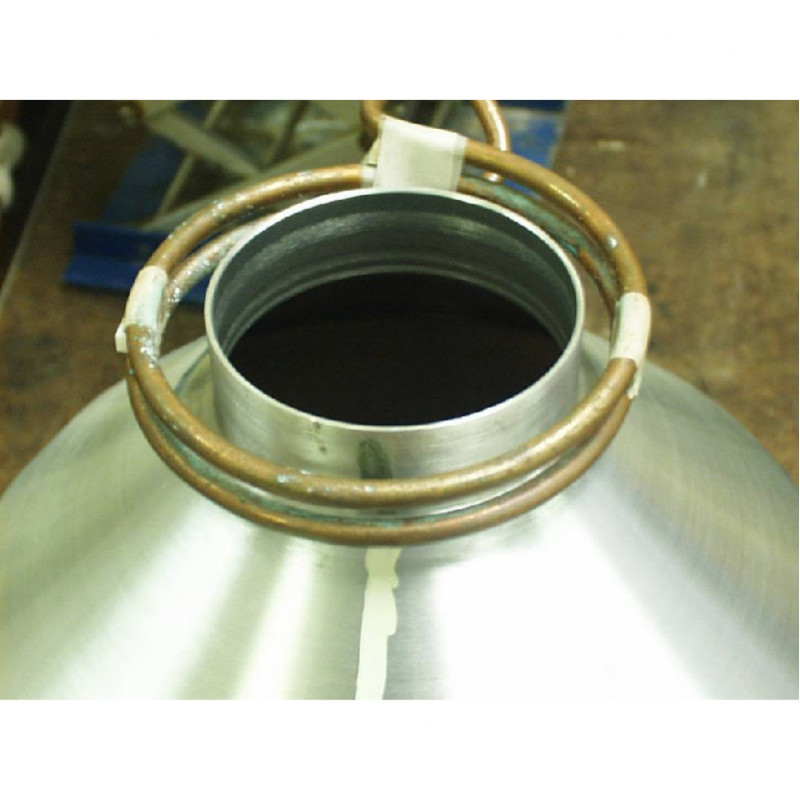

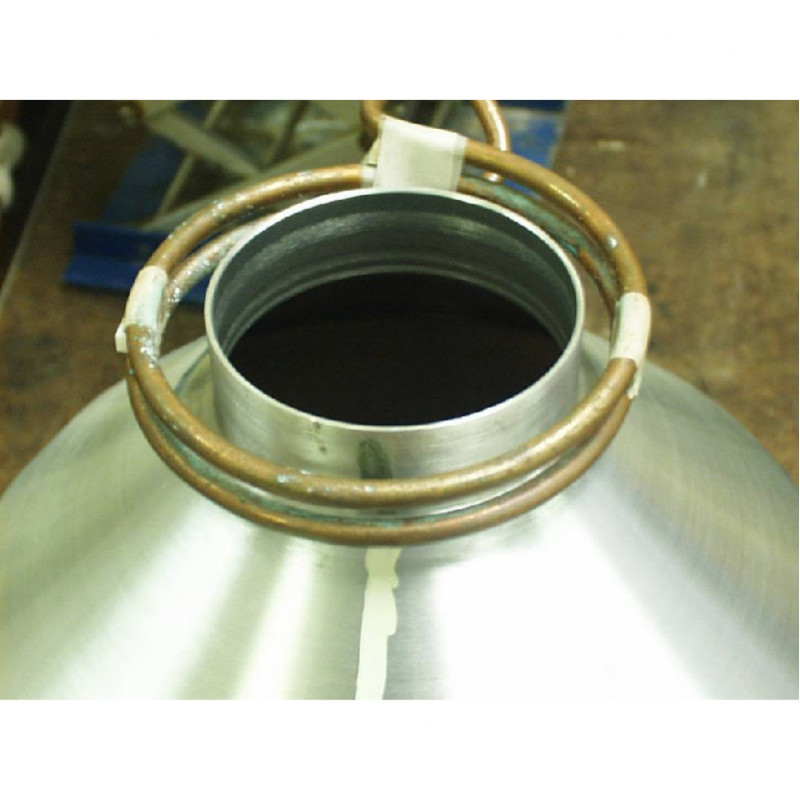

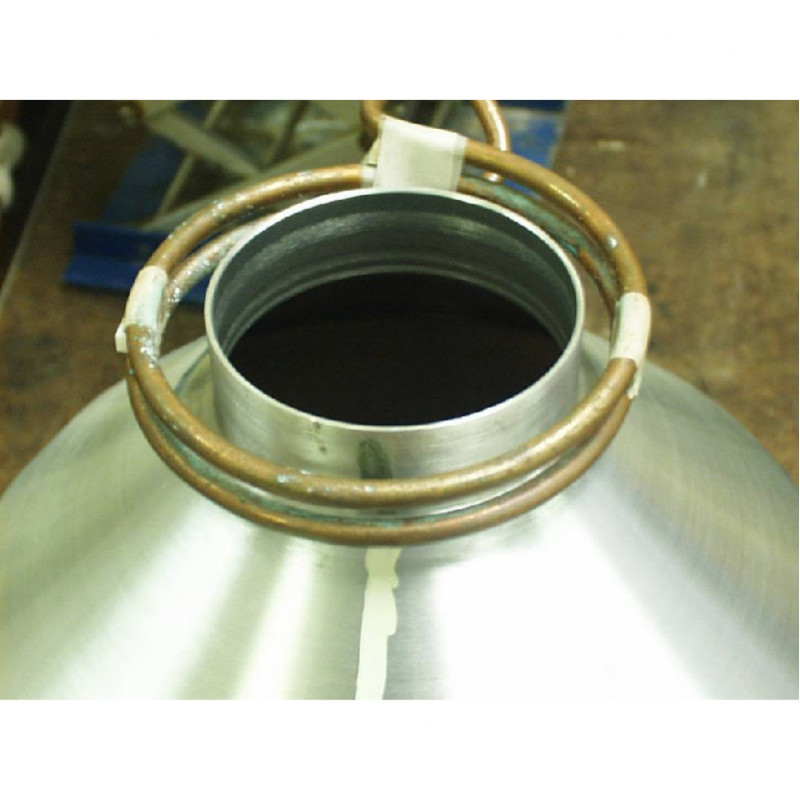

Objective: Annealing a 1” lip on aluminum cryogenic dewar* that has been work hardened during the process of spin forming.

Frequency: 303 kHz

Material: Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thick.

Temperature: 800 °F (427 °C)

A two turn helical coil is used to heat the lip on the cryogenic dewar. The dewar is placed in the coil and power is applied for 2 minutes to anneal the required 1” heat zone.

Are you interested in this product? Do you need additional information or individual pricing?

Objective: Annealing a 1” lip on aluminum cryogenic dewar* that has been work hardened during the process of spin forming.

Frequency: 303 kHz

Material: Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thick.

Temperature: 800 °F (427 °C)

A two turn helical coil is used to heat the lip on the cryogenic dewar. The dewar is placed in the coil and power is applied for 2 minutes to anneal the required 1” heat zone.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent