Category

Photos are for informational purposes only. View product specification

please use latin characters

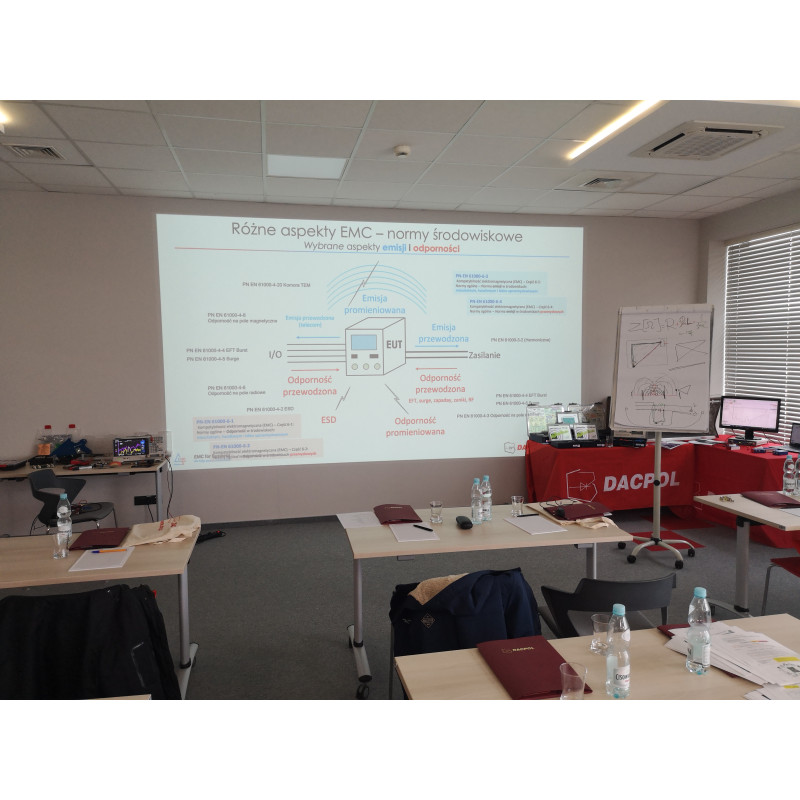

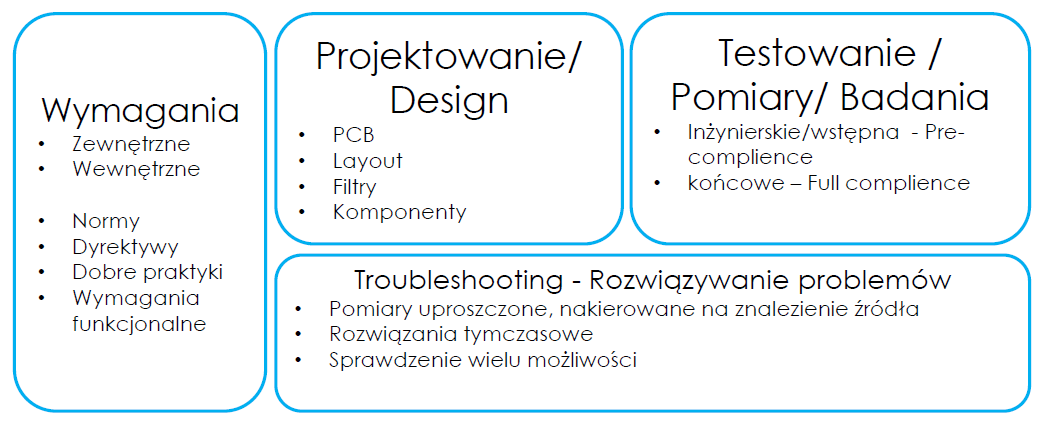

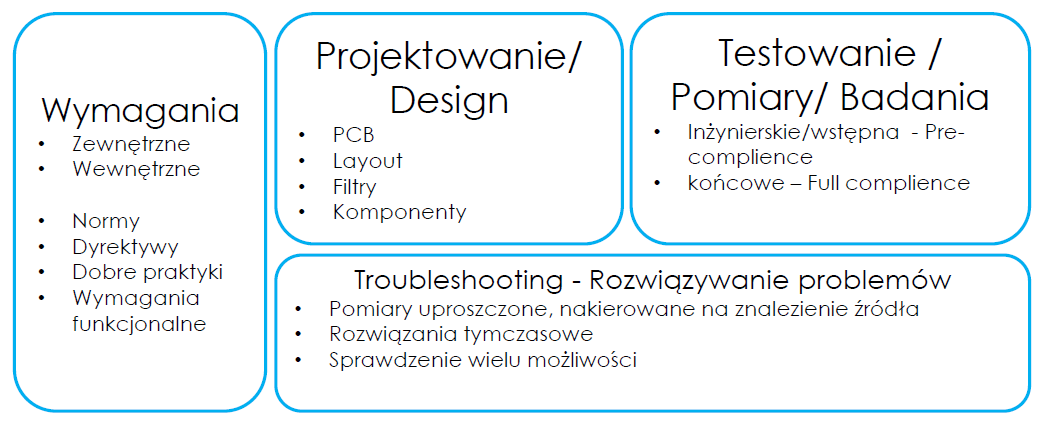

Electromagnetic Interference (EMI) Issues are common in areas where a large number of electrical devices interact with each other. Devices, circuits, and wires can never be completely isolated from electricity, leading to electromagnetic compatibility (EMC) issues. Unfortunately, this means that EMI can be difficult to attribute to a specific source and solve. This is a problem that must be considered, especially during the design phase of electronic circuits, as it is much easier and cheaper to introduce necessary corrections at an early stage. The interference problem may result from one or more issues, so there is no one-size-fits-all solution for every application.

To resolve the EMI problem without guessing or wasting time on false leads, a defined research process should be followed. At Dacpol, we assist in this process. The steps are similar to those used to address power quality issues. The study should consist of the following test procedures:

• Identifying the Source of EMI: by determining what EMI affects and how frequently, you can identify potential sources of the problem.

• Testing and Analyzing Collected Data: testing and gathering data about the potential source and emissions will be necessary using specialized tools. This data will help determine what kind of modifications need to be made.

• Modifying the Existing System: identifying and applying changes or solutions to the EMI source based on data analysis. Multiple corrections may be required.

• Verifying Changes and Confirmation: after applying the solution, retesting and checking the source is necessary to ensure the problem was correctly identified and fixed.

The steps listed above are just an overview of the procedure for dealing with electromagnetic interference. It is possible that the process will need to be repeated if the source was incorrectly identified and the same issues continue to occur in the final stage.

To meet the needs of customers related to assessing the level of interference in electrical circuits and electronic systems, DACPOL and engineers from Langer EMV-Technik GmbH offer services related to detecting weak points in digital systems and analyzing interference. Our emission and immunity measurement technology, as well as integrated circuit testing systems, are mainly used during the product development stage and are applied in systems worldwide. Individual advisory services for preliminary compliance help developers and designers quickly find solutions to complex EMC issues in the development of integrated circuits, devices, and modules.

As part of the services provided, there is the possibility to conduct tests on the client’s equipment. To prepare the analysis, the following are required:

• two functional product samples,

• circuit documentation,

• disassembled PCB and/or circuit design,

• an engineer from your company familiar with the project,

• records of previous measurements,

Examples of elements to be tested include connectors. The EMC characteristics largely depend on the quality of connectors at interfaces. The connector design determines the characteristics of external interference coupling with internal signals and the decoupling of internal signals. Using an inductance measurement station, the coupling inductance of cables and connectors is determined. This parameter describes the quality of EMC of connectors or cables and allows for optimization prospects during development.

The scope of measurements is determined based on the client’s needs. We will design and manufacture printed circuit boards, conduct measurements (with the client, if required), and prepare a detailed test report. The client is responsible only for the test software, with the option of using our support if necessary.

Are you interested in this product? Do you need additional information or individual pricing?

Electromagnetic Interference (EMI) Issues are common in areas where a large number of electrical devices interact with each other. Devices, circuits, and wires can never be completely isolated from electricity, leading to electromagnetic compatibility (EMC) issues. Unfortunately, this means that EMI can be difficult to attribute to a specific source and solve. This is a problem that must be considered, especially during the design phase of electronic circuits, as it is much easier and cheaper to introduce necessary corrections at an early stage. The interference problem may result from one or more issues, so there is no one-size-fits-all solution for every application.

To resolve the EMI problem without guessing or wasting time on false leads, a defined research process should be followed. At Dacpol, we assist in this process. The steps are similar to those used to address power quality issues. The study should consist of the following test procedures:

• Identifying the Source of EMI: by determining what EMI affects and how frequently, you can identify potential sources of the problem.

• Testing and Analyzing Collected Data: testing and gathering data about the potential source and emissions will be necessary using specialized tools. This data will help determine what kind of modifications need to be made.

• Modifying the Existing System: identifying and applying changes or solutions to the EMI source based on data analysis. Multiple corrections may be required.

• Verifying Changes and Confirmation: after applying the solution, retesting and checking the source is necessary to ensure the problem was correctly identified and fixed.

The steps listed above are just an overview of the procedure for dealing with electromagnetic interference. It is possible that the process will need to be repeated if the source was incorrectly identified and the same issues continue to occur in the final stage.

To meet the needs of customers related to assessing the level of interference in electrical circuits and electronic systems, DACPOL and engineers from Langer EMV-Technik GmbH offer services related to detecting weak points in digital systems and analyzing interference. Our emission and immunity measurement technology, as well as integrated circuit testing systems, are mainly used during the product development stage and are applied in systems worldwide. Individual advisory services for preliminary compliance help developers and designers quickly find solutions to complex EMC issues in the development of integrated circuits, devices, and modules.

As part of the services provided, there is the possibility to conduct tests on the client’s equipment. To prepare the analysis, the following are required:

• two functional product samples,

• circuit documentation,

• disassembled PCB and/or circuit design,

• an engineer from your company familiar with the project,

• records of previous measurements,

Examples of elements to be tested include connectors. The EMC characteristics largely depend on the quality of connectors at interfaces. The connector design determines the characteristics of external interference coupling with internal signals and the decoupling of internal signals. Using an inductance measurement station, the coupling inductance of cables and connectors is determined. This parameter describes the quality of EMC of connectors or cables and allows for optimization prospects during development.

The scope of measurements is determined based on the client’s needs. We will design and manufacture printed circuit boards, conduct measurements (with the client, if required), and prepare a detailed test report. The client is responsible only for the test software, with the option of using our support if necessary.

Basics of Electromagnetic Compatibility: What It Is and Why It's Important? 1 of 8

Basics of Electromagnetic Compatibility: What It Is and Why It's Important? 1 of 8

Basics of Electromagnetic Compatibility: What Is It and Why Is It Important? 2 of 8

Basics of Electromagnetic Compatibility: What Is It and Why Is It Important? 2 of 8

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent