Category

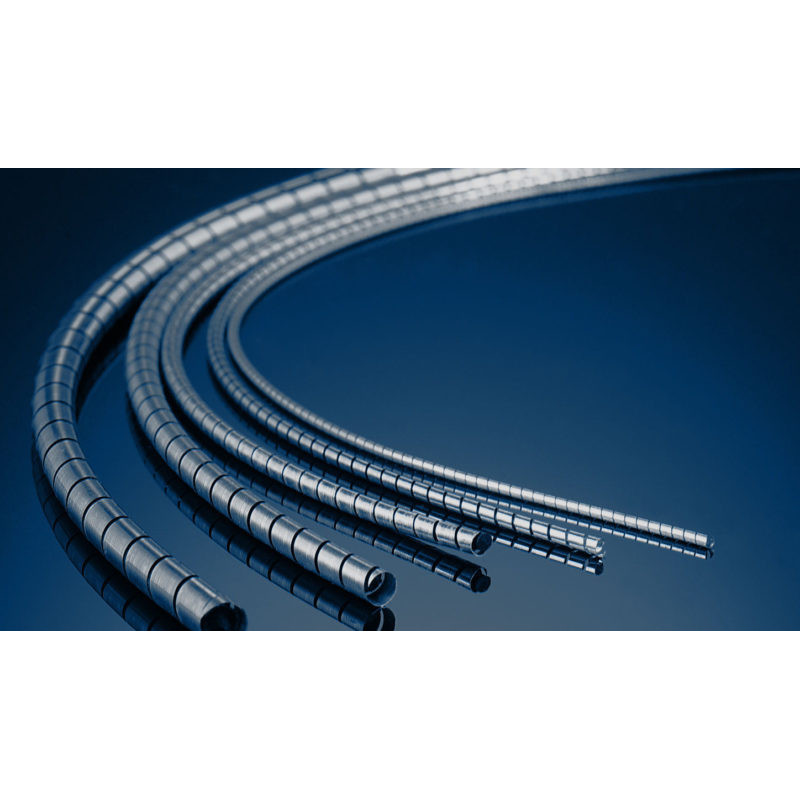

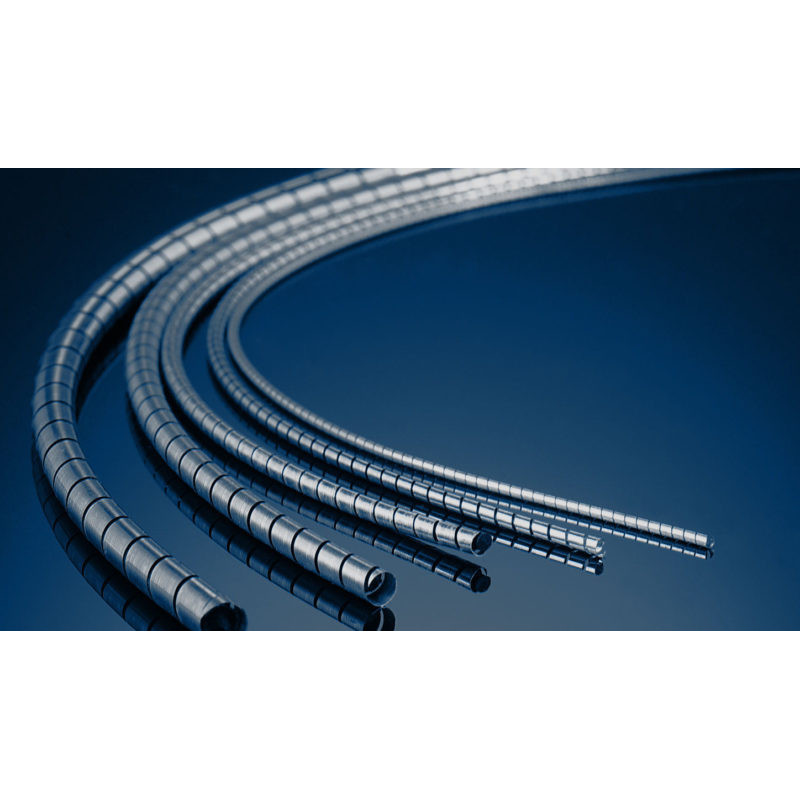

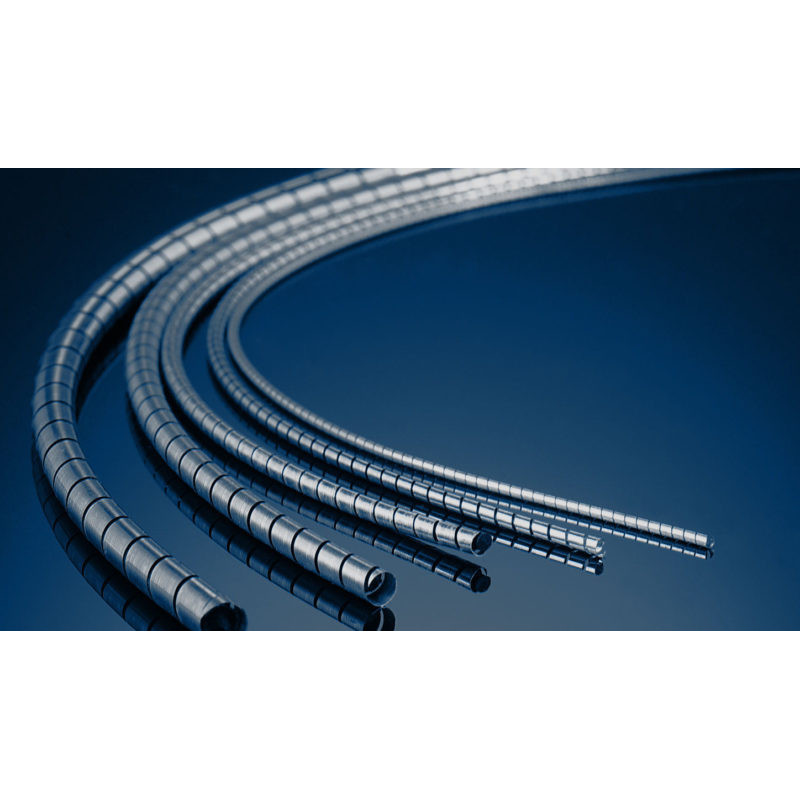

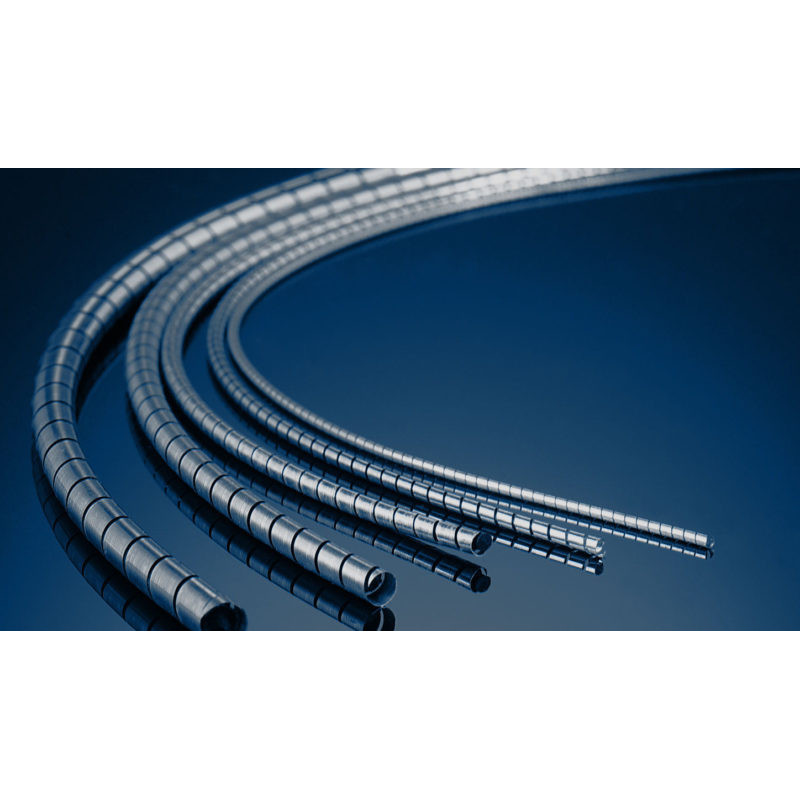

Photos are for informational purposes only. View product specification

please use latin characters

| Ultra Quick-Shield Part Numbers (Tin Plated Stainless Steel) | Recommended Groove Dimensions | |||||

| Diameter | Standard Force* | Moderate Force | Low Force | Depth (L) +.002”-.000” | Width (G) +.007”-.005” | Width (W) +.000”-.002” |

| .034” ± .002” | TNI-02 | TNM-02 NC**/*** | -- | .023” | .046” | .033” |

| .047” ± .002” | TNI-03 | TNM-03 NC**/*** | -- | .035” | .063” | .045” |

| .063” ± .003” | TNI-04 | TNM-04 NC | TNL-04 NC*** | .046” | .094” | .060” |

| .070” ± .003” | TNI-.070 | TNM-.070 NC | TNL-.070 NC | .053” | .094” | .067” |

| .078” ± .003” | TNI-05 | TNM-05 NC | TNL-05 NC*** | .059” | .109” | .075” |

| .094” ± .004” | TNI-06 | TNM-06 NC | TNL-06 NC*** | .070” | .125” | .090” |

| .103” ± .004” | TNI-.103 | TNM-.103 NC | TNL-.103 NC*** | .077” | .141” | .099” |

| .109” ± .004” | TNI-07*** | TNM-07 NC | TNL-07 NC | .082” | .156” | .105” |

| .125” ± .004” | TNI-08*** | TNM-08 NC | TNL-08 NC | .094” | .171” | .121” |

| .139” ± .005” | TNI-.139 | TNM-.139 NC | TNL-.139 NC | .104” | .187” | .134” |

| .141” ± .005” | TNI-09 | TNM-09 NC | TNL-09 NC | .105” | .187” | .136” |

| .172” ± .005” | TNI-11 | TNM-11 NC | TNL-11 NC | .128” | .234” | .165” |

| .187” ± .006” | TNI-12*** | TNM-12 NC*** | TNL-12 NC | .140” | .250” | .181” |

| .250” ± .007” | TNI-16*** | TNM-16 NC | TNL-16 NC | .185” | .343” | .240” |

| .312” ± .009” | TNI-20*** | TNM-20 NC*** | TNL-20 NC | .234” | .422” | |

The affordable cost and superior shielding of this gasket make it an excellent choice for high-end commercial applications. Combining it with a die-cast or molded "pinch boss" groove gives you the optimal price/performance combination.

MATERIALS

SHIELDING QUALITY These gaskets can offer shielding quality in excess of 150 dB at frequencies between 100 kHz and 1 GHz. The shielding quality may vary depending on the specific application.

COMPRESSION FORCE Ultra Quick-Shield gaskets come in three different resiliencies (as shown below). Optimal compression of the gasket is 25% of the diameter of the spiral. Since the force to compress the gasket is a function of the cube of the thickness of the stainless steel ribbon, the compression forces shown are approximate.

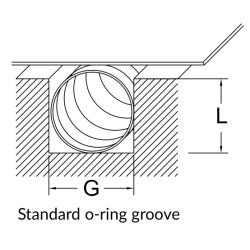

MOUNTING This gasket is groove mounted.

PLATING To specify tin plating for RoHS compliance, replace the "T" with "IW" at the beginning of the part number. Additional plating charges may apply.

This gasket is not recommended for high humidity or salt-fog applications because the edges of the gasket are not plated. If high humidity or salt-fog environments are to be encountered, the edge plated version of our Spira-Shield gasket is recommended.

CORD INSERT To keep costs low, we recommend you omit the cord usually used in the spiral. However, if over-compression of the gasket is a concern or problem, remove the "NC" from the part number on the moderate and low force series gaskets.

Example: TNL-06 NC will come without a cord. TNL-06 will include cord. All Standard Force gaskets come without cord (no NC required).

CUSTOM SIZES We can manufacture Ultra Quick-Shield gaskets in any size diameter, from .034" up to approximately 1.5". The functional length of the part may be short at very large diameters. Please contact us with your requirements.

SPLICING OPTIONS Spira has created three standard options to treat the splicing of material in our spool selection.

Availability: Please be advised that this product is out of stock

You can place a pre-order, report your interest in the product by clicking the "Ask for availability" button.

| Ultra Quick-Shield Part Numbers (Tin Plated Stainless Steel) | Recommended Groove Dimensions | |||||

| Diameter | Standard Force* | Moderate Force | Low Force | Depth (L) +.002”-.000” | Width (G) +.007”-.005” | Width (W) +.000”-.002” |

| .034” ± .002” | TNI-02 | TNM-02 NC**/*** | -- | .023” | .046” | .033” |

| .047” ± .002” | TNI-03 | TNM-03 NC**/*** | -- | .035” | .063” | .045” |

| .063” ± .003” | TNI-04 | TNM-04 NC | TNL-04 NC*** | .046” | .094” | .060” |

| .070” ± .003” | TNI-.070 | TNM-.070 NC | TNL-.070 NC | .053” | .094” | .067” |

| .078” ± .003” | TNI-05 | TNM-05 NC | TNL-05 NC*** | .059” | .109” | .075” |

| .094” ± .004” | TNI-06 | TNM-06 NC | TNL-06 NC*** | .070” | .125” | .090” |

| .103” ± .004” | TNI-.103 | TNM-.103 NC | TNL-.103 NC*** | .077” | .141” | .099” |

| .109” ± .004” | TNI-07*** | TNM-07 NC | TNL-07 NC | .082” | .156” | .105” |

| .125” ± .004” | TNI-08*** | TNM-08 NC | TNL-08 NC | .094” | .171” | .121” |

| .139” ± .005” | TNI-.139 | TNM-.139 NC | TNL-.139 NC | .104” | .187” | .134” |

| .141” ± .005” | TNI-09 | TNM-09 NC | TNL-09 NC | .105” | .187” | .136” |

| .172” ± .005” | TNI-11 | TNM-11 NC | TNL-11 NC | .128” | .234” | .165” |

| .187” ± .006” | TNI-12*** | TNM-12 NC*** | TNL-12 NC | .140” | .250” | .181” |

| .250” ± .007” | TNI-16*** | TNM-16 NC | TNL-16 NC | .185” | .343” | .240” |

| .312” ± .009” | TNI-20*** | TNM-20 NC*** | TNL-20 NC | .234” | .422” | |

The affordable cost and superior shielding of this gasket make it an excellent choice for high-end commercial applications. Combining it with a die-cast or molded "pinch boss" groove gives you the optimal price/performance combination.

MATERIALS

SHIELDING QUALITY These gaskets can offer shielding quality in excess of 150 dB at frequencies between 100 kHz and 1 GHz. The shielding quality may vary depending on the specific application.

COMPRESSION FORCE Ultra Quick-Shield gaskets come in three different resiliencies (as shown below). Optimal compression of the gasket is 25% of the diameter of the spiral. Since the force to compress the gasket is a function of the cube of the thickness of the stainless steel ribbon, the compression forces shown are approximate.

MOUNTING This gasket is groove mounted.

PLATING To specify tin plating for RoHS compliance, replace the "T" with "IW" at the beginning of the part number. Additional plating charges may apply.

This gasket is not recommended for high humidity or salt-fog applications because the edges of the gasket are not plated. If high humidity or salt-fog environments are to be encountered, the edge plated version of our Spira-Shield gasket is recommended.

CORD INSERT To keep costs low, we recommend you omit the cord usually used in the spiral. However, if over-compression of the gasket is a concern or problem, remove the "NC" from the part number on the moderate and low force series gaskets.

Example: TNL-06 NC will come without a cord. TNL-06 will include cord. All Standard Force gaskets come without cord (no NC required).

CUSTOM SIZES We can manufacture Ultra Quick-Shield gaskets in any size diameter, from .034" up to approximately 1.5". The functional length of the part may be short at very large diameters. Please contact us with your requirements.

SPLICING OPTIONS Spira has created three standard options to treat the splicing of material in our spool selection.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent