Category

Photos are for informational purposes only. View product specification

please use latin characters

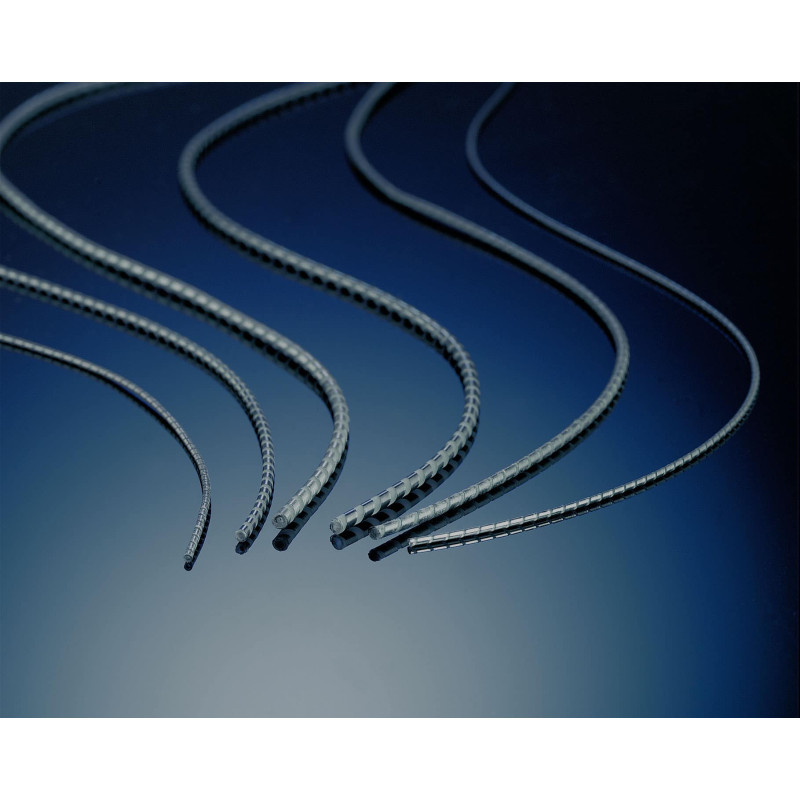

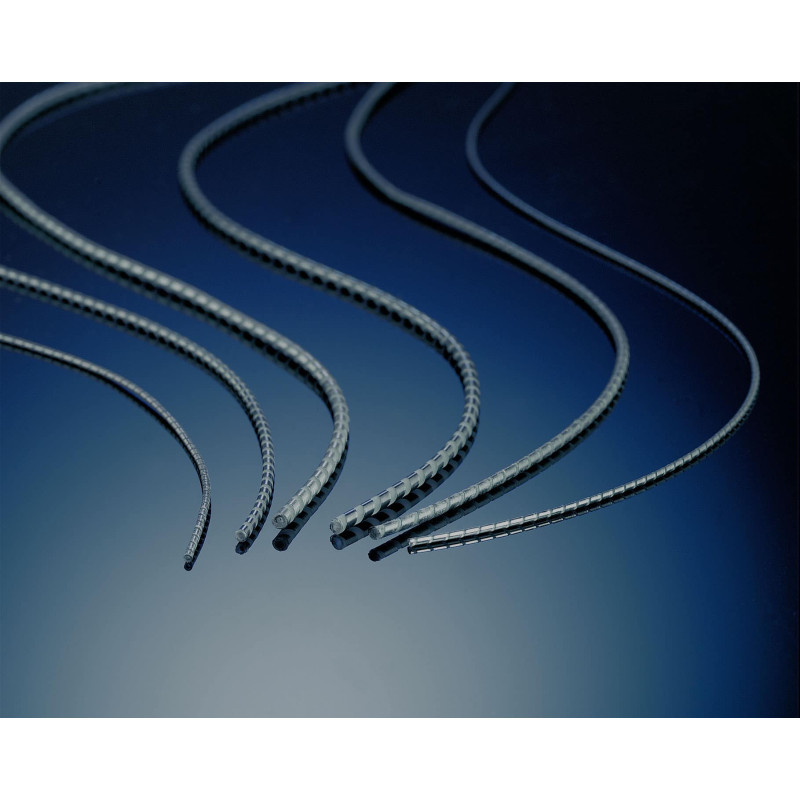

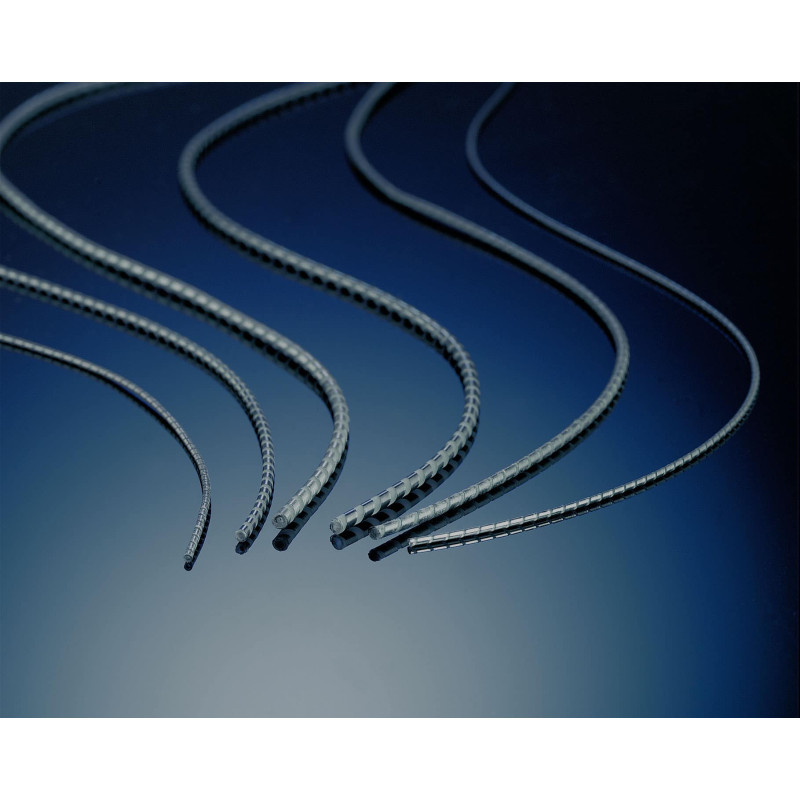

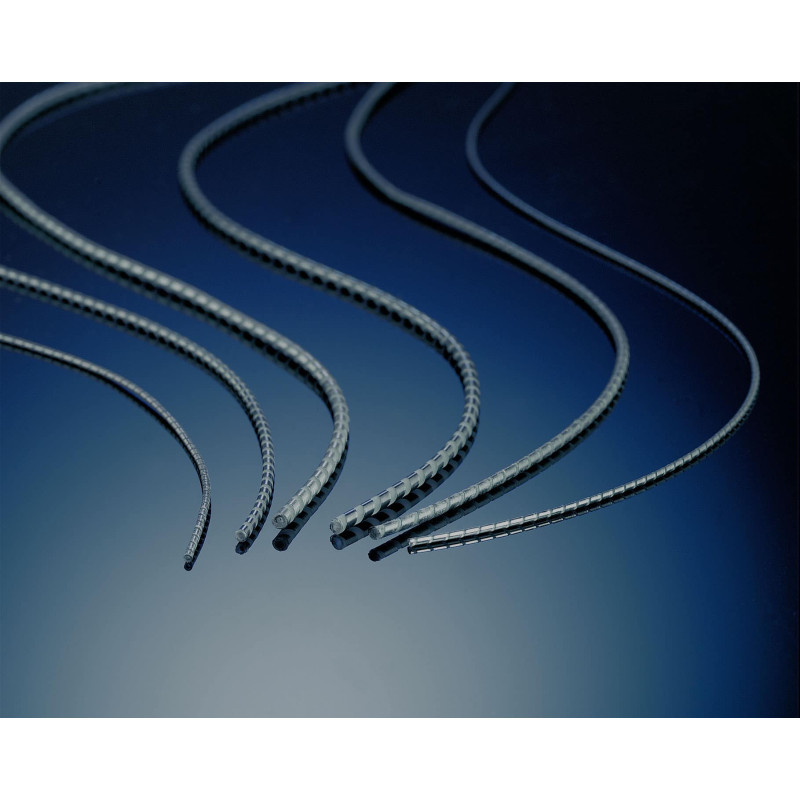

Spira’s Flexi-Shield gasket offers the best of both worlds. This gasket combines the EMI shielding performance of our other spiral gaskets with the rain/wind/dust sealing of an elastomer. A special process wraps our highly conductive spiral around a soft silicone tube. This results in gaskets that are very easy to handle, are rugged enough to be used in demanding sliding applications, provide as little as two pounds of closure force per inch, and offer moderate to high shielding, depending on the materials chosen. The low force series is especially well-suited to shielding the front/rear panels of VME/VXI and similar enclosures.

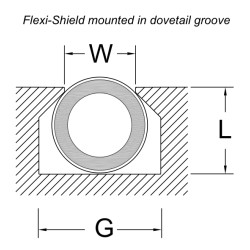

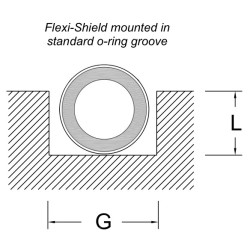

| Flexi-Shield Part Numbers (Stainless Steel) | Recommended Groove Dimensions* | |||||

| Diameter | Standard Force | Moderate Force | Low Force | Depth (L) +.002”-.000” | Width (G) +.007”-.005” | Width (W) +.000”-.002” |

| .063”± .003” | SQ-04 | MQ-04 | LQ-04 | .046” | .094” | .060” |

| .070”± .003” | SQ-.070 | MQ-.070 | LQ-.070 | .053” | .094” | .067” |

| .094”± .004” | SQ-06 | MQ-06 | LQ-06 | .070” | .125” | .090” |

| .103”± .004” | SQ-.103 | MQ-.103 | LQ-.103 | .077” | .141” | .099” |

| .106”± .004” | SQ-.106 | MQ-.106 | LQ-.106 | .080” | .141” | .102” |

| .125”± .004” | SQ-08 | MQ-08 | LQ-08 | .094” | .171” | .121” |

| .139”± .005” | SQ-.139 | MQ-.139 | LQ-.139 | .104" | .187" | .134" |

| .141”± .005” | SQ-09 | MQ-09 | LQ-09 | .105” | .187” | .136” |

| .187”± .008” | SQ-12 | MQ-12 | LQ-12 | .140” | .250” | .181” |

| .250”± .010” | SQ-16 | MQ-16 | LQ-16 | .185” | .343” | .240” |

* Different groove required for VME/VXI and similar front/rear panel shielding. Refer to our VME/VXI Shielding Design Guide for details.

Note: Larger sizes may be available. Contact us for more information.

Whether you need moderate to high shielding levels, rain/wind/dust sealing, or simply want the ease of handling that the inner tube provides, Spira’s Flexi-Shield comes through for you. All the benefits for one low cost!

SHIELDING QUALITY We offer stainless steel for moderate shielding quality and optional tin plating for higher shielding levels. All shielding quality results are based on tests against tin plated joint surfaces. The shielding quality may vary depending on your specific application.

LOW CLOSURE FORCE The low force series is ideal for applications with very little closure force (approximately two pounds per linear inch compression). The gasket resists compression set, is very easy to handle and will provide a rain/wind/dust seal.

VME/VXI AND SIMILAR FRONT/REAR PANELS The low force gasket is the best choice for shielding front and back panels of VME/VXI and similar enclosures. The gaskets are easy to insert, and testing shows no visible wear after 1,000 insertions! Flexi-Shield gaskets are manufactured from a continuous piece of metal, so they have no small pieces to break off and short out equipment. For specific design information, refer to our VME/VXI Shielding Design Guide.

SLIDING APPLICATIONS All versions of Flexi-Shield are ideally suited for sliding applications. Specify moderate or standard force Flexi-Shield where extreme durability is required.

MATERIALS

ENVIRONMENTAL SEALING Our testing shows that all sizes and all resiliencies offer a rain/wind/dust seal. (We have other gaskets that provide an immersion seal). Contact us for free samples to determine if this gasket meets your environmental sealing needs!

COMPRESSION FORCE Flexi-Shield gaskets come in three different resiliencies (as shown below). Optimal compression of the gasket is 25% of the diameter of the spiral (except in the case of VME/VXI designs. Please refer to our VME/VXI Shielding Design Guide). Since the force to compress the gasket is a function of the cube of the thickness of the stainless steel ribbon, the compression forces shown are approximate.

MOUNTING This gasket is groove mounted. Refer to our VME/VXI Shielding Design Guide for more information.

MATERIALS AND PLATING Plating for stainless steel Flexi-Shield can be specified using the following prefix:

Tin plated beryllium copper material may be substituted if desired. An edge plated version is also available for high humidity/salt-fog environments. Please contact us for more information.

SPECIAL TUBING Fluorosilicone tubing can be specified as follows (may include extra charges):

SPLICING OPTIONS Spira has created three standard options to treat the splicing of material in our spool selection.

Are you interested in this product? Do you need additional information or individual pricing?

Spira’s Flexi-Shield gasket offers the best of both worlds. This gasket combines the EMI shielding performance of our other spiral gaskets with the rain/wind/dust sealing of an elastomer. A special process wraps our highly conductive spiral around a soft silicone tube. This results in gaskets that are very easy to handle, are rugged enough to be used in demanding sliding applications, provide as little as two pounds of closure force per inch, and offer moderate to high shielding, depending on the materials chosen. The low force series is especially well-suited to shielding the front/rear panels of VME/VXI and similar enclosures.

| Flexi-Shield Part Numbers (Stainless Steel) | Recommended Groove Dimensions* | |||||

| Diameter | Standard Force | Moderate Force | Low Force | Depth (L) +.002”-.000” | Width (G) +.007”-.005” | Width (W) +.000”-.002” |

| .063”± .003” | SQ-04 | MQ-04 | LQ-04 | .046” | .094” | .060” |

| .070”± .003” | SQ-.070 | MQ-.070 | LQ-.070 | .053” | .094” | .067” |

| .094”± .004” | SQ-06 | MQ-06 | LQ-06 | .070” | .125” | .090” |

| .103”± .004” | SQ-.103 | MQ-.103 | LQ-.103 | .077” | .141” | .099” |

| .106”± .004” | SQ-.106 | MQ-.106 | LQ-.106 | .080” | .141” | .102” |

| .125”± .004” | SQ-08 | MQ-08 | LQ-08 | .094” | .171” | .121” |

| .139”± .005” | SQ-.139 | MQ-.139 | LQ-.139 | .104" | .187" | .134" |

| .141”± .005” | SQ-09 | MQ-09 | LQ-09 | .105” | .187” | .136” |

| .187”± .008” | SQ-12 | MQ-12 | LQ-12 | .140” | .250” | .181” |

| .250”± .010” | SQ-16 | MQ-16 | LQ-16 | .185” | .343” | .240” |

* Different groove required for VME/VXI and similar front/rear panel shielding. Refer to our VME/VXI Shielding Design Guide for details.

Note: Larger sizes may be available. Contact us for more information.

Whether you need moderate to high shielding levels, rain/wind/dust sealing, or simply want the ease of handling that the inner tube provides, Spira’s Flexi-Shield comes through for you. All the benefits for one low cost!

SHIELDING QUALITY We offer stainless steel for moderate shielding quality and optional tin plating for higher shielding levels. All shielding quality results are based on tests against tin plated joint surfaces. The shielding quality may vary depending on your specific application.

LOW CLOSURE FORCE The low force series is ideal for applications with very little closure force (approximately two pounds per linear inch compression). The gasket resists compression set, is very easy to handle and will provide a rain/wind/dust seal.

VME/VXI AND SIMILAR FRONT/REAR PANELS The low force gasket is the best choice for shielding front and back panels of VME/VXI and similar enclosures. The gaskets are easy to insert, and testing shows no visible wear after 1,000 insertions! Flexi-Shield gaskets are manufactured from a continuous piece of metal, so they have no small pieces to break off and short out equipment. For specific design information, refer to our VME/VXI Shielding Design Guide.

SLIDING APPLICATIONS All versions of Flexi-Shield are ideally suited for sliding applications. Specify moderate or standard force Flexi-Shield where extreme durability is required.

MATERIALS

ENVIRONMENTAL SEALING Our testing shows that all sizes and all resiliencies offer a rain/wind/dust seal. (We have other gaskets that provide an immersion seal). Contact us for free samples to determine if this gasket meets your environmental sealing needs!

COMPRESSION FORCE Flexi-Shield gaskets come in three different resiliencies (as shown below). Optimal compression of the gasket is 25% of the diameter of the spiral (except in the case of VME/VXI designs. Please refer to our VME/VXI Shielding Design Guide). Since the force to compress the gasket is a function of the cube of the thickness of the stainless steel ribbon, the compression forces shown are approximate.

MOUNTING This gasket is groove mounted. Refer to our VME/VXI Shielding Design Guide for more information.

MATERIALS AND PLATING Plating for stainless steel Flexi-Shield can be specified using the following prefix:

Tin plated beryllium copper material may be substituted if desired. An edge plated version is also available for high humidity/salt-fog environments. Please contact us for more information.

SPECIAL TUBING Fluorosilicone tubing can be specified as follows (may include extra charges):

SPLICING OPTIONS Spira has created three standard options to treat the splicing of material in our spool selection.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent