Category

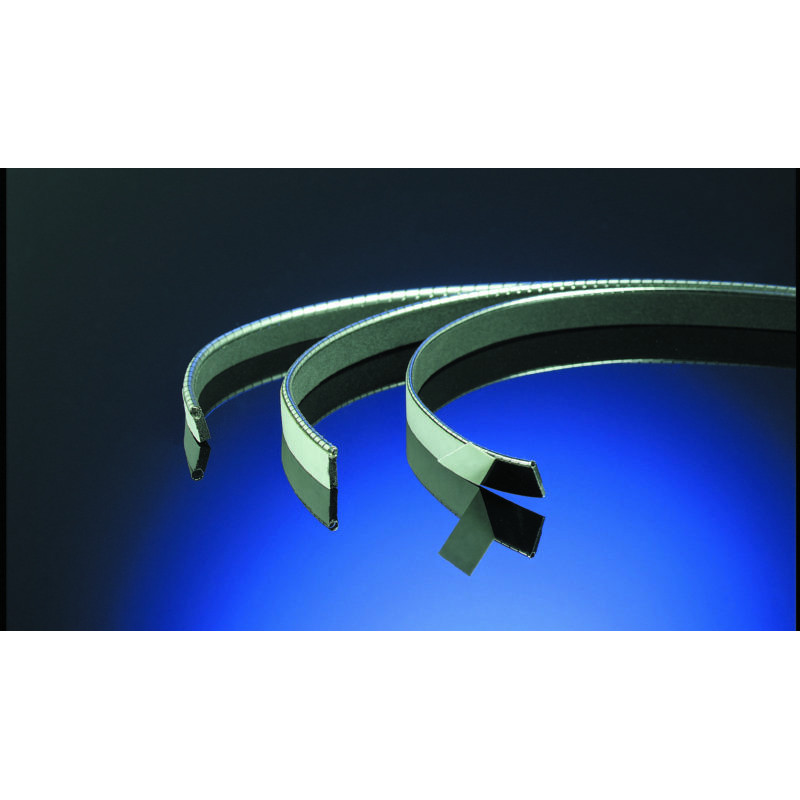

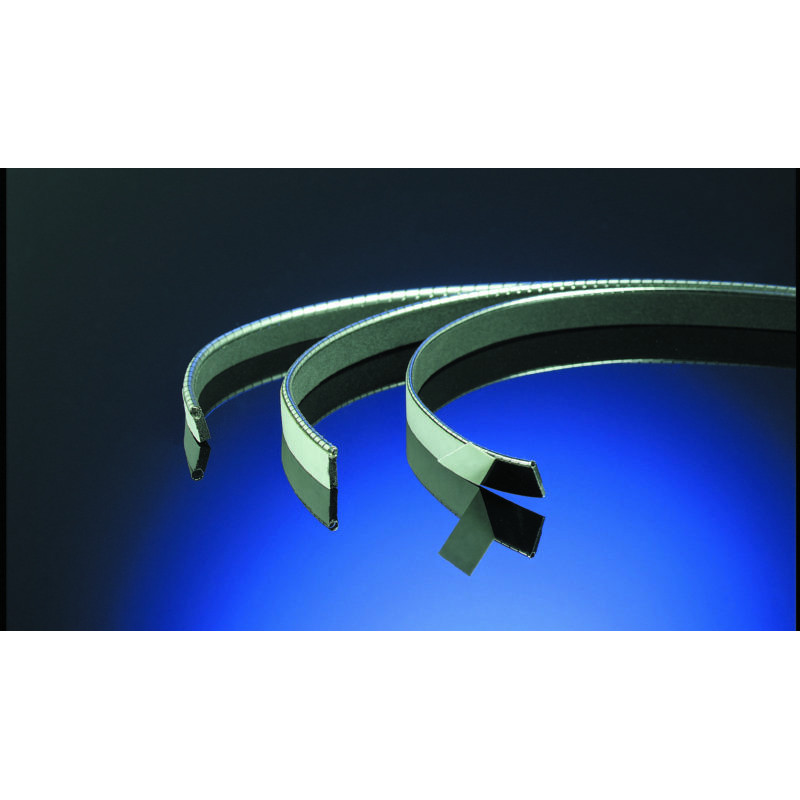

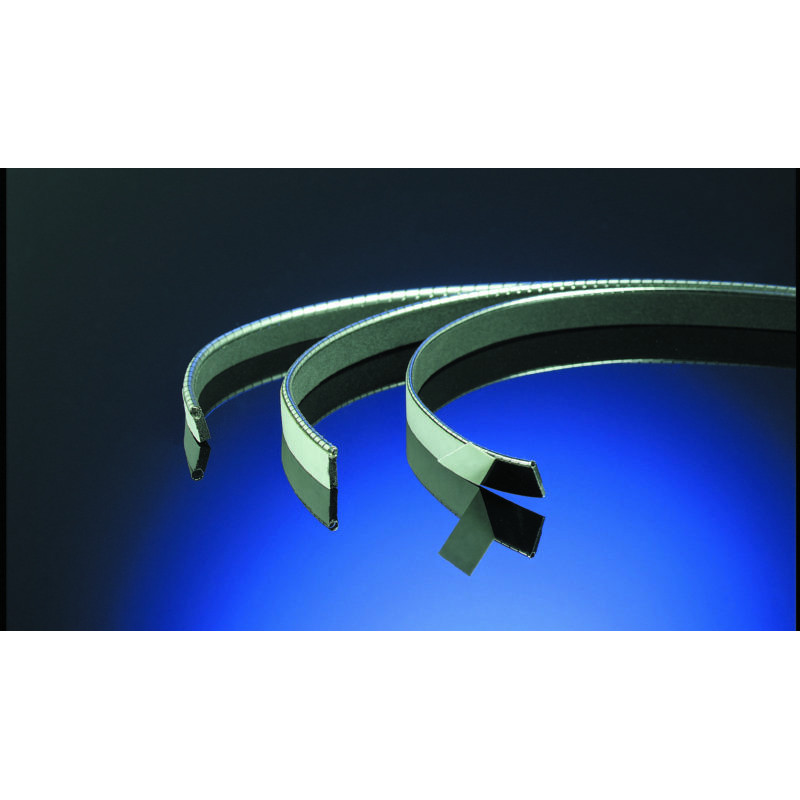

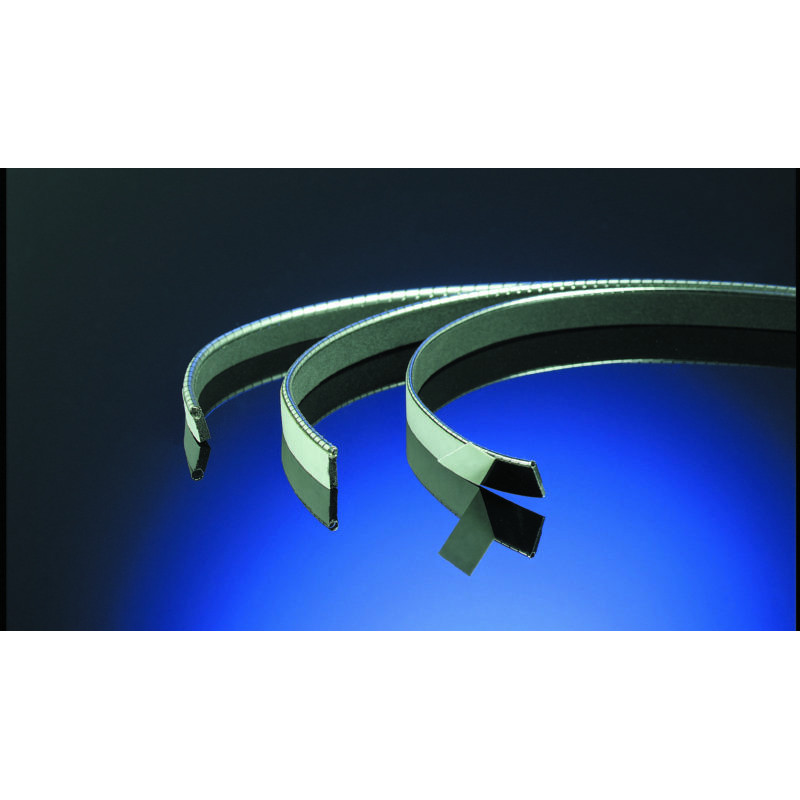

Photos are for informational purposes only. View product specification

please use latin characters

| Gasket Dimensions | Quick-Strip Part Numbers | ||||

| Elastomer Thickness (A) | Elastomer Width (B) | Spiral Diameter (D) | Standard Force* | Moderate Force | Low Force |

| .063” | .250” | .063” | NI-0422-A /P | NM-0422-A NC /P | NL-0422-A NC /P |

| .375” | NI-0423-A /P | NM-0423-A NC /P | NL-0423-A NC /P | ||

| .094” | .250” | .094” | NI-0632-A /P | NM-0632-A NC /P | NL-0632-A NC /P |

| .375” | NI-0633-A /P | NM-0633-A NC /P | NL-0633-A NC /P | ||

| .125” | .250” | .125” | NI-0842-A /P | NM-0842-A NC /P | NL-0842-A NC /P |

| .375” | NI-0843-A /P | NM-0843-A NC /P | NL-0843-A NC /P | ||

| .187” | .250” | .187” | NI-1262-A /P | NM-1262-A NC /P | NL-1262-A NC /P |

*All standard force gaskets come without a cord.

Quick-Strip can either be used in a continuous length along the perimeter of a chassis, or cut into small pieces and used at strategic intervals. When meeting relatively low shielding requirements such as for the FCC and European Community, you can often meet those requirements by using a few small pieces of the gasket. This allows you to get the shielding you need, while minimizing both the gasket and labor costs. The best way to figure out how many segments you need is during the testing phase of the design. Place a few 1” pieces of gasket around the perimeter of your box. Run a baseline test and then add and subtract gasket pieces until you find the optimal number. This also allows you to upgrade by adding a few more pieces if you later need to meet more stringent requirements or the frequency of your internal electronics goes up in subsequent product modifications.

Spiral: Quick-Shield, Stainless steel.

Elastomer: Neoprene sponge with adhesive backing.

This gasket offers shielding quality greater than 95 dB in continuous lengths. Small pieces of Quick-Strip will offer less shielding; how much less will depend on the size of the gap between pieces and your particular design.

Quick-Strip gaskets come in three different resiliencies (as shown below). Optimal compression of the gasket is 25% of the diameter of the spiral. The compression forces shown are approximate.

Standard Force: ~30 pounds per linear inch compression.

Moderate Force: ~10 pounds per linear inch compression.

Low Force: ~1.5 pounds per linear inch compression.

This gasket is surface mounted.

Quick Strip comes standard with a stainless steel Quick-Strip spiral. Any of our other spiral materials may be custom configured to meet your needs. Please contact us for more information.

To keep costs low, we recommend you omit the cord usually used in the spiral. However, if over-compression of the gasket is a concern or problem, remove the “NC” from the part number on the moderate and low force series gaskets.

Example: NM-0632-A /P will include cord.

All Standard Force gaskets come without cord (no NC required).

We recommend the use of neoprene sponge elastomer because it is the lowest cost of popular elastomers. Silicone sponge elastomer can also be specified as shown below. (For solid elastomers, please see the Spira-Strip gasket on page 19).

/C: Silicone sponge (Example: NM-0632-A /C)

Neoprene sponge elastomers only come with pressure sensitive adhesive (PSA) backing. Silicone sponge elastomers can be ordered without adhesive backing by dropping the -A designation in the part number.

Example: NM-0632 NC /P

Are you interested in this product? Do you need additional information or individual pricing?

| Gasket Dimensions | Quick-Strip Part Numbers | ||||

| Elastomer Thickness (A) | Elastomer Width (B) | Spiral Diameter (D) | Standard Force* | Moderate Force | Low Force |

| .063” | .250” | .063” | NI-0422-A /P | NM-0422-A NC /P | NL-0422-A NC /P |

| .375” | NI-0423-A /P | NM-0423-A NC /P | NL-0423-A NC /P | ||

| .094” | .250” | .094” | NI-0632-A /P | NM-0632-A NC /P | NL-0632-A NC /P |

| .375” | NI-0633-A /P | NM-0633-A NC /P | NL-0633-A NC /P | ||

| .125” | .250” | .125” | NI-0842-A /P | NM-0842-A NC /P | NL-0842-A NC /P |

| .375” | NI-0843-A /P | NM-0843-A NC /P | NL-0843-A NC /P | ||

| .187” | .250” | .187” | NI-1262-A /P | NM-1262-A NC /P | NL-1262-A NC /P |

*All standard force gaskets come without a cord.

Quick-Strip can either be used in a continuous length along the perimeter of a chassis, or cut into small pieces and used at strategic intervals. When meeting relatively low shielding requirements such as for the FCC and European Community, you can often meet those requirements by using a few small pieces of the gasket. This allows you to get the shielding you need, while minimizing both the gasket and labor costs. The best way to figure out how many segments you need is during the testing phase of the design. Place a few 1” pieces of gasket around the perimeter of your box. Run a baseline test and then add and subtract gasket pieces until you find the optimal number. This also allows you to upgrade by adding a few more pieces if you later need to meet more stringent requirements or the frequency of your internal electronics goes up in subsequent product modifications.

Spiral: Quick-Shield, Stainless steel.

Elastomer: Neoprene sponge with adhesive backing.

This gasket offers shielding quality greater than 95 dB in continuous lengths. Small pieces of Quick-Strip will offer less shielding; how much less will depend on the size of the gap between pieces and your particular design.

Quick-Strip gaskets come in three different resiliencies (as shown below). Optimal compression of the gasket is 25% of the diameter of the spiral. The compression forces shown are approximate.

Standard Force: ~30 pounds per linear inch compression.

Moderate Force: ~10 pounds per linear inch compression.

Low Force: ~1.5 pounds per linear inch compression.

This gasket is surface mounted.

Quick Strip comes standard with a stainless steel Quick-Strip spiral. Any of our other spiral materials may be custom configured to meet your needs. Please contact us for more information.

To keep costs low, we recommend you omit the cord usually used in the spiral. However, if over-compression of the gasket is a concern or problem, remove the “NC” from the part number on the moderate and low force series gaskets.

Example: NM-0632-A /P will include cord.

All Standard Force gaskets come without cord (no NC required).

We recommend the use of neoprene sponge elastomer because it is the lowest cost of popular elastomers. Silicone sponge elastomer can also be specified as shown below. (For solid elastomers, please see the Spira-Strip gasket on page 19).

/C: Silicone sponge (Example: NM-0632-A /C)

Neoprene sponge elastomers only come with pressure sensitive adhesive (PSA) backing. Silicone sponge elastomers can be ordered without adhesive backing by dropping the -A designation in the part number.

Example: NM-0632 NC /P

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent