Category

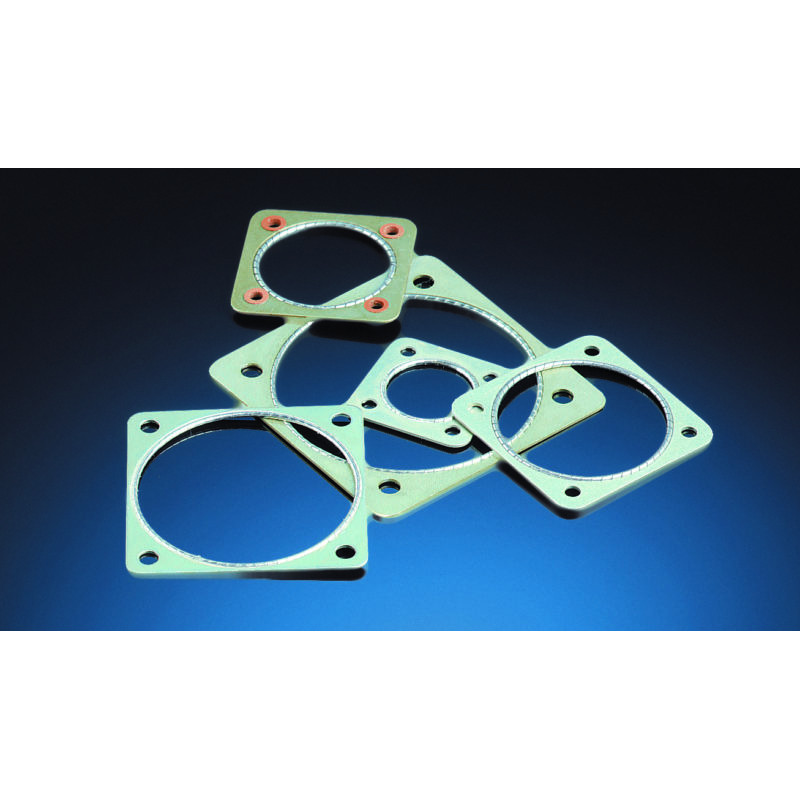

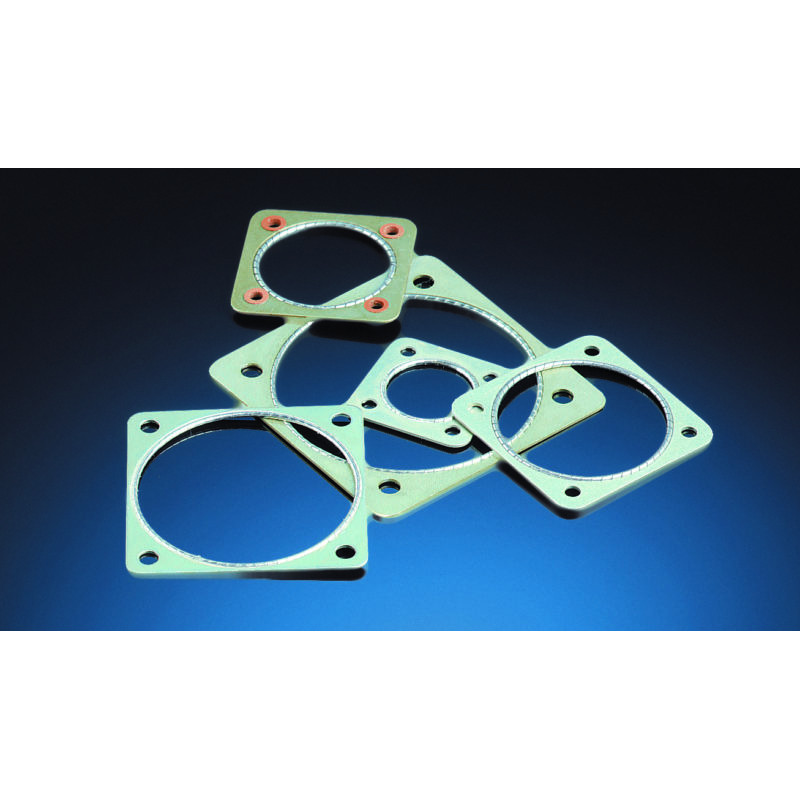

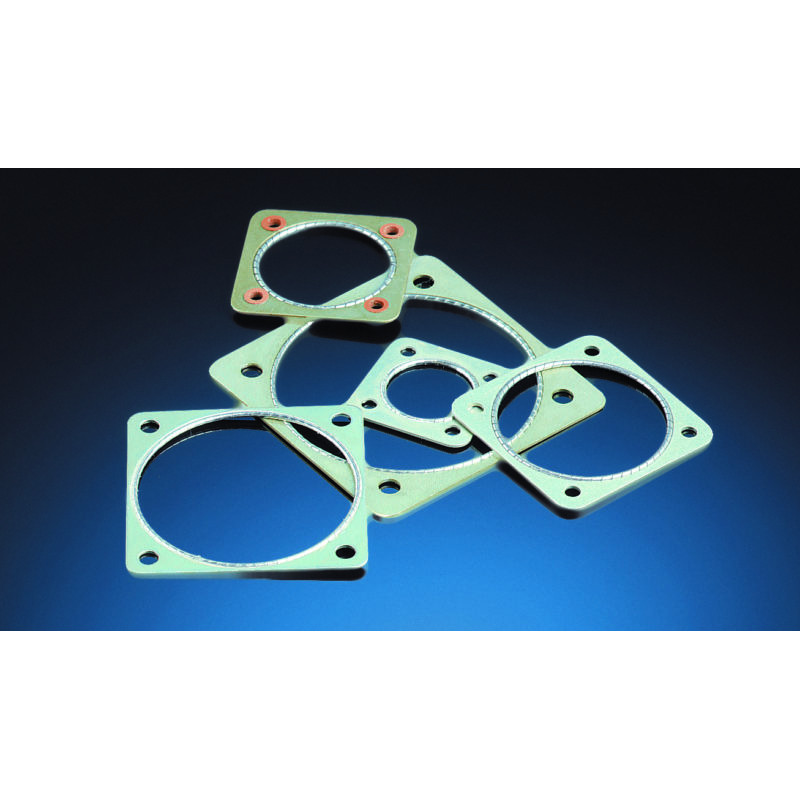

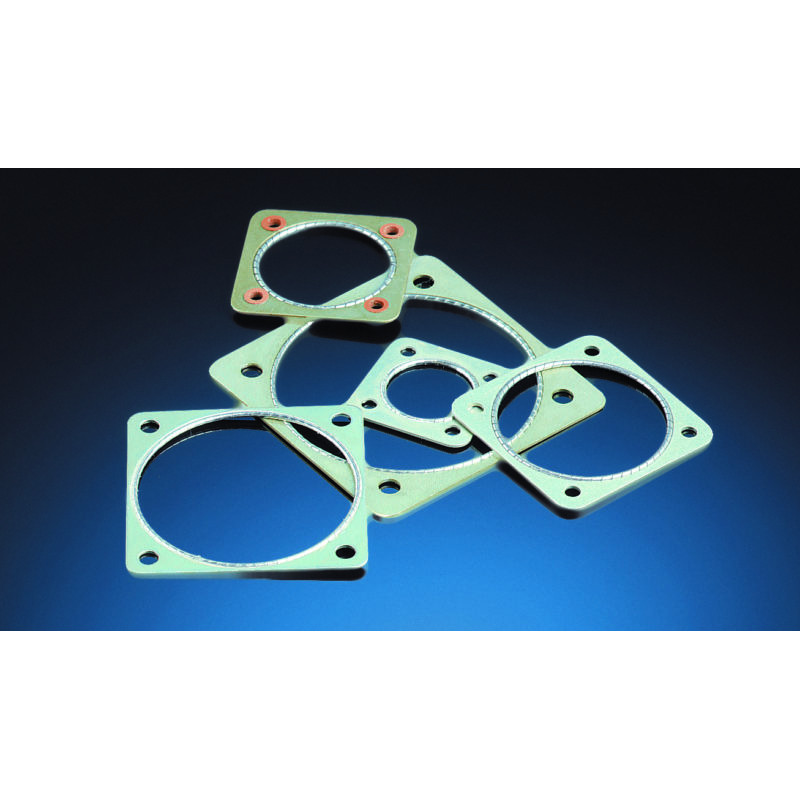

Photos are for informational purposes only. View product specification

please use latin characters

Spira’s EMI-Only Connector-Seal gaskets are designed to provide an EMI seal in flange-mounted connectors for the life of a system. These gaskets are extremely durable, and have achieved up to 1,000 insertions in actual use.

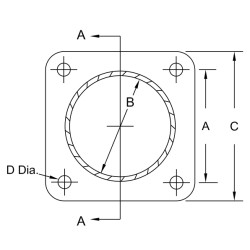

| For Use with Connectors | A ±.005” |

B +.010” -.005” |

C ±.020” |

D +.010” -.005” |

||||

| Dash No. | MIL-C-26482, 26500, 83723 Series 1 & 3 NAS 1599 “B” & “T” Size | MIL-C-38999 | MIL-C-81703 Size | |||||

| 1 & 2 Size | 3 & 4 Size | |||||||

| 01 | 8 | 8 | .594” | .562” | .937” | .125” | ||

| 02 | 3 | .625” | .623” | 1.000” | .125” | |||

| 03 | 10 | 9 & 10 | 9 | 7 | .719” | .687” | 1.062” | .125” |

| 04 | .798” | .883” | 1.200” | .125” | ||||

| 05 | 12 | 11 & 12 | 10 & 11 | .812” | .812” | 1.156” | .125” | |

| 06 | 12 | .812” | .828” | 1.200” | .125” | |||

| 07 | 14 | 13 & 14 | 12 & 13 | 19 | .906” | .947” | 1.200” | .125” |

| 08 | .928” | 1.070” | 1.375” | .125” | ||||

| 09 | 16 | 15 & 16 | 14 & 15 | 27 | .969” | 1.063” | 1.375” | .125” |

| 10 | .978” | 1.133” | 1.437” | .125” | ||||

| 11 | 18 | 17 & 18 | 16 & 17 | 1.062” | 1.187” | 1.437” | .125” | |

| 12 | 1.140” | 1.325” | 1.625” | .125” | ||||

| 13 | 37 | 1.187” | 1.325” | 1.562” | .125” | |||

| 14 | 20 | 19 & 20 | 18 & 19 | 1.156” | 1.312” | 1.563” | .125” | |

| 15 | 1.238” | 1.508” | 1.825” | .125” | ||||

| 16 | 22 | 20 & 21 | 1.250” | 1.437” | 1.687” | .125” | ||

| 17 | 24 | 22 & 23 | 1.375” | 1.562” | 1.825” | .152” | ||

| 18 | 1.392” | 1.633” | 1.937” | .152” | ||||

| 19 | 61 | 1.436” | 1.570” | 1.825” | .125” | |||

| 20 | 25 | 24 & 25 | 1.500” | 1.682” | 1.937” | .152” | ||

| 21 | 1.568” | 1.830” | 2.250” | .152” | ||||

| 22 | 1.716” | 2.030” | 2.375” | .173” | ||||

| 23 | .753” | .771” | 1.100” | .125” | ||||

| 28 | 32 | 1.750” | 2.062” | 2.312” | .173” | |||

| 29 | 1.062” | 1.250” | 1.437” | .125” | ||||

| 32 | 1.938” | 2.186” | 2.550” | .173” | ||||

| 33 | 24 & 25 | 1.500” | 1.682” | 1.850” | .152” | |||

| 34 | 36 | 1.938” | 2.312” | 2.600” | .173” | |||

| 35 | 1.750” | 1.846” | 2.250” | .173” | ||||

| 39 | 1.187” | 1.437” | 1.687” | .125” | ||||

| 40 | 1.437” | 1.726” | 1.880” | .125” | ||||

Note that the dash numbers and sizes are different for each type of Connector-Seal gasket: the Environmental Connector-Seal Standard-Mount (ECS), the Front-Mount Environmental Connector-Seal (FMECS) and the EMI-Only version (CS).

The “CS” EMI-Only Connector-Seal is a more durable, cost effective replacement of Spira’s original Connector-Seal (“SSCG”) and can be either back or front-mounted. The CS EMI-Only gasket is similar to the EMI & Environmental Connector-Seal (ECS), but due to frame dimensions it does not provide environmental sealing.

When choosing a gasket, select an inside diameter that easily clears the connector barrel. The shielding is achieved by making contact between the two joint surfaces, not by touching the barrel. The original SSCG gaskets can still be ordered if desired.

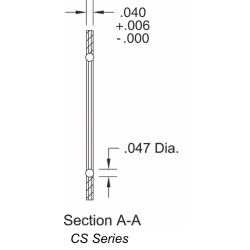

CS Frame: Silicone (/S) or Fluorosilicone (/F) sealing over a stainless steel frame.

CS Spiral: Spira-Shield standard force tin/lead plated beryllium copper.

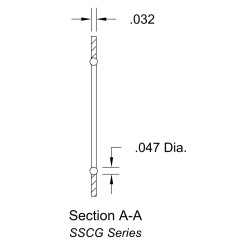

SSCG Frame: Chem-film plated aluminum (old style, replaced by CS)

SSCG Spiral: Enduro-Shield moderate force tin/lead plated beryllium copper.

SSCG Core: Cured silicone adhesive.

RoHS compliant options are also available.

Connector-Seal gaskets offer shielding quality from 116 to 152 dB. The level is dependent on contact surfaces and may vary depending on your specific application. Refer to our Shielding Quality charts for more complete performance data.

Optimal compression of the gasket is 25% of the diameter of the spiral. The compression force stated is approximate. When installing the gasket, care must be taken to clear the mounting pins one at a time.

CS Series: ~30 pounds per linear inch compression force required.

SSCG Series: ~10 pounds per linear inch compression force required.

The gasket is electroplated, 90% tin, 10% lead per AMS-P-81728 (edges unplated). Plating options can be specified by adding a prefix before the part number:

E: Edge tin/lead plating (includes edges) for high humidity or salt-fog environments

IW: RoHS compliant tin plating (Example: ECS-IW-21 /S)

EIW: RoHS compliant edge tin plating for high humidity or salt-fog

The SSCG version uses a Spira-Seal gasket with a standard core of solid silicone adhesive. A special core can be specified by adding an option to the end of the part number:

-F: Fluorosilicone (Example: CS-T-16 /F)

-O: Silicone that meets outgassing requirements

-Z: Silicone which is a non-acetic acid adhesive (per MIL-A-46146)

The frame on our CS series gaskets is stainless steel sealed on both sides by silicone or fluorosilicone elastomeric material. The SSCG series gaskets have a chem-film plated aluminum frame. The CS gaskets are still EMI-only protection due to the sizing.

Availability: Please be advised that this product is out of stock

You can place a pre-order, report your interest in the product by clicking the "Ask for availability" button.

Spira’s EMI-Only Connector-Seal gaskets are designed to provide an EMI seal in flange-mounted connectors for the life of a system. These gaskets are extremely durable, and have achieved up to 1,000 insertions in actual use.

| For Use with Connectors | A ±.005” |

B +.010” -.005” |

C ±.020” |

D +.010” -.005” |

||||

| Dash No. | MIL-C-26482, 26500, 83723 Series 1 & 3 NAS 1599 “B” & “T” Size | MIL-C-38999 | MIL-C-81703 Size | |||||

| 1 & 2 Size | 3 & 4 Size | |||||||

| 01 | 8 | 8 | .594” | .562” | .937” | .125” | ||

| 02 | 3 | .625” | .623” | 1.000” | .125” | |||

| 03 | 10 | 9 & 10 | 9 | 7 | .719” | .687” | 1.062” | .125” |

| 04 | .798” | .883” | 1.200” | .125” | ||||

| 05 | 12 | 11 & 12 | 10 & 11 | .812” | .812” | 1.156” | .125” | |

| 06 | 12 | .812” | .828” | 1.200” | .125” | |||

| 07 | 14 | 13 & 14 | 12 & 13 | 19 | .906” | .947” | 1.200” | .125” |

| 08 | .928” | 1.070” | 1.375” | .125” | ||||

| 09 | 16 | 15 & 16 | 14 & 15 | 27 | .969” | 1.063” | 1.375” | .125” |

| 10 | .978” | 1.133” | 1.437” | .125” | ||||

| 11 | 18 | 17 & 18 | 16 & 17 | 1.062” | 1.187” | 1.437” | .125” | |

| 12 | 1.140” | 1.325” | 1.625” | .125” | ||||

| 13 | 37 | 1.187” | 1.325” | 1.562” | .125” | |||

| 14 | 20 | 19 & 20 | 18 & 19 | 1.156” | 1.312” | 1.563” | .125” | |

| 15 | 1.238” | 1.508” | 1.825” | .125” | ||||

| 16 | 22 | 20 & 21 | 1.250” | 1.437” | 1.687” | .125” | ||

| 17 | 24 | 22 & 23 | 1.375” | 1.562” | 1.825” | .152” | ||

| 18 | 1.392” | 1.633” | 1.937” | .152” | ||||

| 19 | 61 | 1.436” | 1.570” | 1.825” | .125” | |||

| 20 | 25 | 24 & 25 | 1.500” | 1.682” | 1.937” | .152” | ||

| 21 | 1.568” | 1.830” | 2.250” | .152” | ||||

| 22 | 1.716” | 2.030” | 2.375” | .173” | ||||

| 23 | .753” | .771” | 1.100” | .125” | ||||

| 28 | 32 | 1.750” | 2.062” | 2.312” | .173” | |||

| 29 | 1.062” | 1.250” | 1.437” | .125” | ||||

| 32 | 1.938” | 2.186” | 2.550” | .173” | ||||

| 33 | 24 & 25 | 1.500” | 1.682” | 1.850” | .152” | |||

| 34 | 36 | 1.938” | 2.312” | 2.600” | .173” | |||

| 35 | 1.750” | 1.846” | 2.250” | .173” | ||||

| 39 | 1.187” | 1.437” | 1.687” | .125” | ||||

| 40 | 1.437” | 1.726” | 1.880” | .125” | ||||

Note that the dash numbers and sizes are different for each type of Connector-Seal gasket: the Environmental Connector-Seal Standard-Mount (ECS), the Front-Mount Environmental Connector-Seal (FMECS) and the EMI-Only version (CS).

The “CS” EMI-Only Connector-Seal is a more durable, cost effective replacement of Spira’s original Connector-Seal (“SSCG”) and can be either back or front-mounted. The CS EMI-Only gasket is similar to the EMI & Environmental Connector-Seal (ECS), but due to frame dimensions it does not provide environmental sealing.

When choosing a gasket, select an inside diameter that easily clears the connector barrel. The shielding is achieved by making contact between the two joint surfaces, not by touching the barrel. The original SSCG gaskets can still be ordered if desired.

CS Frame: Silicone (/S) or Fluorosilicone (/F) sealing over a stainless steel frame.

CS Spiral: Spira-Shield standard force tin/lead plated beryllium copper.

SSCG Frame: Chem-film plated aluminum (old style, replaced by CS)

SSCG Spiral: Enduro-Shield moderate force tin/lead plated beryllium copper.

SSCG Core: Cured silicone adhesive.

RoHS compliant options are also available.

Connector-Seal gaskets offer shielding quality from 116 to 152 dB. The level is dependent on contact surfaces and may vary depending on your specific application. Refer to our Shielding Quality charts for more complete performance data.

Optimal compression of the gasket is 25% of the diameter of the spiral. The compression force stated is approximate. When installing the gasket, care must be taken to clear the mounting pins one at a time.

CS Series: ~30 pounds per linear inch compression force required.

SSCG Series: ~10 pounds per linear inch compression force required.

The gasket is electroplated, 90% tin, 10% lead per AMS-P-81728 (edges unplated). Plating options can be specified by adding a prefix before the part number:

E: Edge tin/lead plating (includes edges) for high humidity or salt-fog environments

IW: RoHS compliant tin plating (Example: ECS-IW-21 /S)

EIW: RoHS compliant edge tin plating for high humidity or salt-fog

The SSCG version uses a Spira-Seal gasket with a standard core of solid silicone adhesive. A special core can be specified by adding an option to the end of the part number:

-F: Fluorosilicone (Example: CS-T-16 /F)

-O: Silicone that meets outgassing requirements

-Z: Silicone which is a non-acetic acid adhesive (per MIL-A-46146)

The frame on our CS series gaskets is stainless steel sealed on both sides by silicone or fluorosilicone elastomeric material. The SSCG series gaskets have a chem-film plated aluminum frame. The CS gaskets are still EMI-only protection due to the sizing.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent