-

- Medical Applications with Precision Induction Heating

- Applications for automotive industry

- Soldering

- Brazing

- Aluminum Brazing

- Brazing a magnetic steel cutting tool

- Pin Sealing

- Atmospheric Brazing

- Soldering brass and steel radiator caps

- Carbide Tipping

- Soldering a copper lug and a wire

- Brazing a Copper Tube and Steel Plate

- Soldering Four Fusible Copper Strips

- Soldering a Pair of Magnetic Steel Pins

- Brazing a Steel Part for the Aerospace Industry

- Brazing Brass Assemblies for a Sink Manufacturer

- Heating

- Hot Heading a Steel Wire to Create a Screw

- Induction heating in nanotechnology applications

- Susceptor Heating

- Heating Graphite Discs for an Aerospace Industry

- Levitation heating

- Heating for Tube and Pipe

- Heating aluminum wire to create screens

- Fastener Heating

- Induction Heating for Automotive Manufacturing

- Heating Steel Tubes for an Adhesive Bonding Application

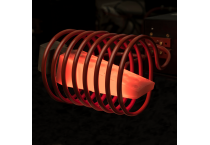

- Preheating for Forging of Steel Pins

- Preheating Parts for Welding

- Preheating Rod Assemblies for Welding

- Induction heating for bolt expansion in steam turbines

- Bonding

- Fiber Optics Heating

- Shrink Fitting

- Stator shrink fitting

- Shrink Fitting an Aluminum Motor Housing

- Shrink Fitting an Assembled Wrist Pin into a Connecting Rod

- Shrink fit a steel gear onto a motor shaft

- Shrink Fitting of Bearings

- Shrink Fitting a Magnetic Steel Gear

- Heating Hammer Bits for Shrink Fitting

- Shrink fitting aluminum pulley to insert inner bearing

- Annealing

- Shell Tempering

- Hardening

- Hardening the teeth of a large saw blade

- Hardening the end of steel hand-held marking stamps

- Compact generator for hardening

- Curing Plastisol

- Coating curing by heating the aluminum block

- Curing epoxy on aluminum copier roller assembly

- Curing plastisol adhesive on an aluminum filter assembly

- Metal Melting

- Melting silicon in graphite crucible for material testing

- Melting the end of a plastic tube to create a seal

- Hot forming

- Forging

- Forging rods of various materials and dimensions

- Catheter Tipping

- Forming a Magnetic Steel Part

- Flattening and Bending Steel Tubes

- Crystal growing

- Getter Firing

- Material Testing

- Staking

- Cap Sealing

- Sealing an Aluminum Cap Seal on a Plastic Jug

- Hermetically sealing a fiber optic cable in a kovar ferrule

- Hermetic Sealing of Stainless Steel Rods with Glass Preforms

- Plastic Reflow - Induction Heat Staking

- Curing Coatings

- Metal-glass Sealing

- Bonding Solar Panel Shingles

- Metal to plastic bonding of beer kegs

- Debonding inserts in manifolds for recycling

- MOCVD

- Induction knife for roof tiles

- Annealing a stainless steel handle

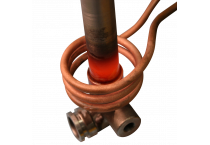

- Annealing of copper pipes

- Anneal an oval cut out on a stainless steel tube prior to extrusion

- Annealing brass and bronze tubing prior to bending to form handrails

- Annealing the end of a hydraulic motor shaft prior to machining

- Annealing lip on aluminum cryogenic dewar

- Coating

- Coating - e.g. car screws

- Glaze removal from the winding wire

- Removing plastic coating from steel tubes

- Flat products, strips, sheets

Industrial induction devices are technologically advanced tools that utilize the phenomenon of electromagnetic induction for material processing or energy transmission. Due to their effectiveness and efficiency, they are essential components in many manufacturing processes. From simple induction furnaces to advanced heating systems, these devices offer fast and precise solutions for a wide spectrum of industrial applications. Their advantages include high energy efficiency, reduced production cycle times, and the ability to control processes in real-time, leading to increased profitability and product quality.