Category

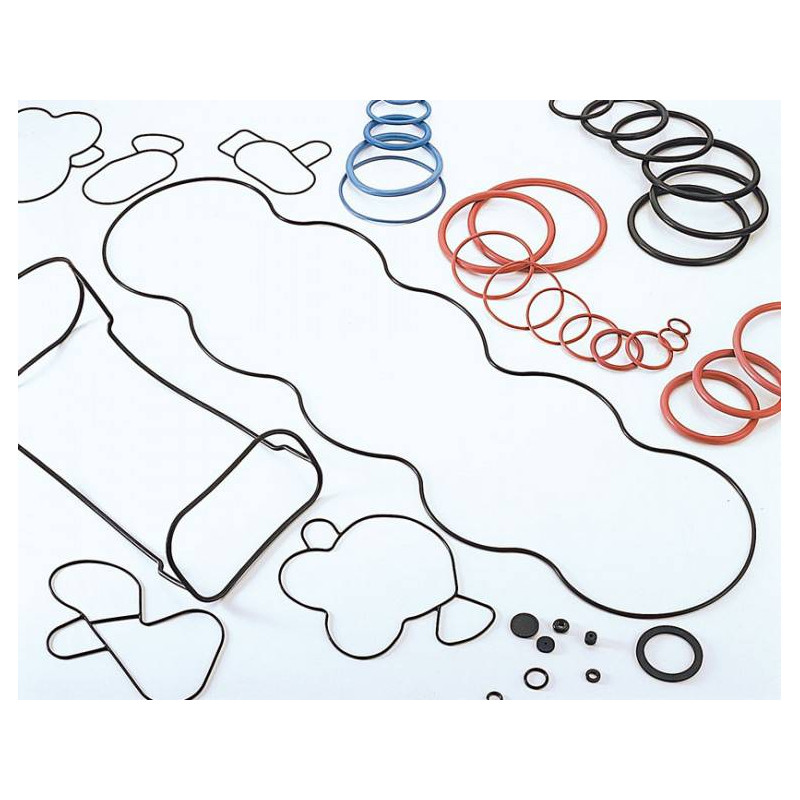

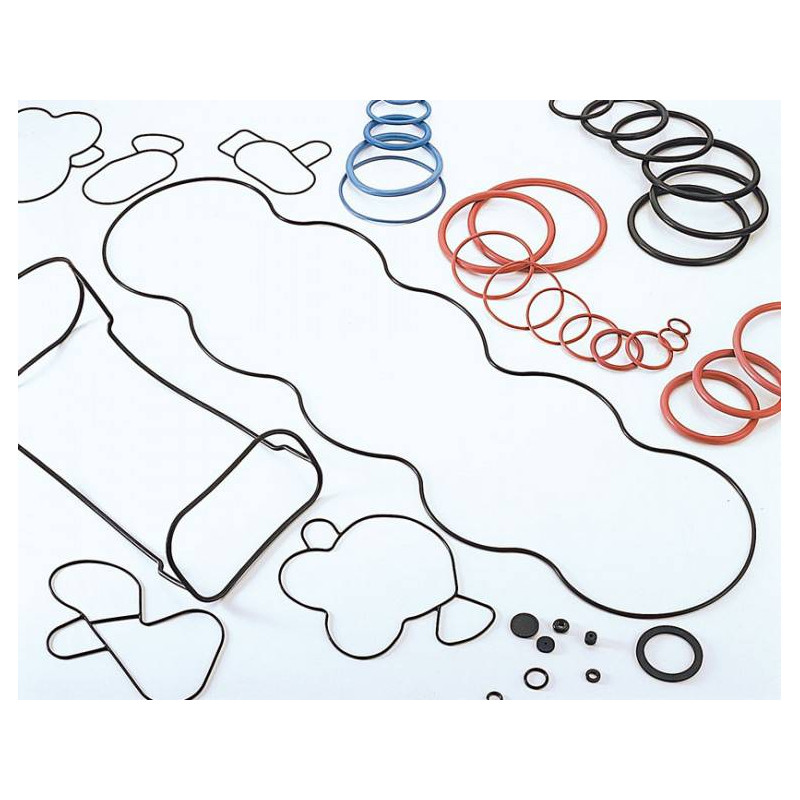

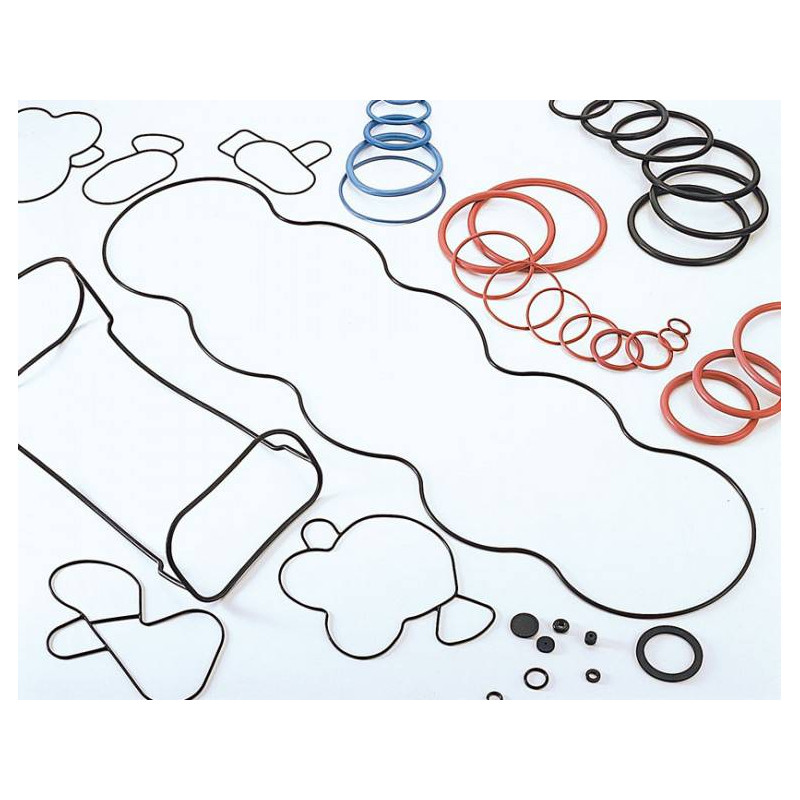

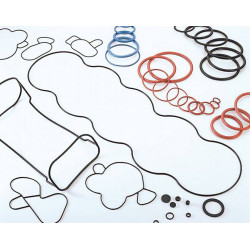

Photos are for informational purposes only. View product specification

please use latin characters

The O-ring is usually housed in a rectangular groove. The DIN standard distinguishes two types of sealing systems, either static or dynamic.

Elastomers are incompressible and react under pressure as the fluids that transmit the forces subjected to pressure from all sides. The circular cross section of the O-ring is deformed between the two surfaces (see Figure 1).

In an installation space without pressure, the required clamping force Po to obtain a sealing, is created by the resistance to deformation of the rubber. The pressure Ps caused by the fluid to be sealed, increases the deformation of the cross section of the seal ring and thus the pressure required for sealing (see Figure 2).

The simplicity of the geometry of the O-ring is the dominant feature of this sealing element. With a suitable choice of the quality of the elastomer and a precise definition of the cross section according to the size of the groove, the O-ring is an efficient, cost- effective and simple sealing system.

The installation spaces are calculated according to the criteria of the standard DIN 3771/5.

The inside diameter of the O-ring may, during the installation, be extended by 6% while the cross section can be compressed by 3 %.

In any given application it is always prudent to adopt the largest possible O-ring cross section in relation to the inside diameter d1 when selecting the cross section d2. It is particularly advisable to select the next larger cross section in connection with unfavorable tolerance conditions, in order to achieve a good sealing effect.

If elastomers come into contact with the media, they can absorb a certain proportion of these media. The capacity depends on the resistance of the elastomer material to the medium.The volume of the installation space must be designed so that the swelling and the thermal expansion due to a temperature increase can be absorbed.

A volumetric swelling was taken into account for the calculation of the width B1 of the housing.If in exceptional cases, a significant swelling is anticipated (8% dynamic sealing , 15% static sealing) the width B1 of the housing must be enlarged accordingly. A retraction should always be avoided.

Radial installation (static and dynamic), internal seal (rod seal)

The O-ring size should be selected so that the inside diameter d1 is at least equal to or larger than the outside diameter d5.

Radial installation (static and dynamic) external seal (piston seal)

The O-ring size should be selected so that the inside diameter d1 is equal to or smaller than groove diameter d3.

Axial, static installation

In axial static installations the pressure direction should be considered when selecting the O-ring.

These installation recommendations are only indications and are intended as approximate guidelines. Users are advised to perform tests validating the installation.

In the DIN 3771/5 standard, each O-ring inside diameter is assigned to a corresponding string section. This assignment should also be observed for the O-rings non-normalized because the degree of compression depends essentially on the tolerances of the cross section thickness and the groove.

Are you interested in this product? Do you need additional information or individual pricing?

The O-ring is usually housed in a rectangular groove. The DIN standard distinguishes two types of sealing systems, either static or dynamic.

Elastomers are incompressible and react under pressure as the fluids that transmit the forces subjected to pressure from all sides. The circular cross section of the O-ring is deformed between the two surfaces (see Figure 1).

In an installation space without pressure, the required clamping force Po to obtain a sealing, is created by the resistance to deformation of the rubber. The pressure Ps caused by the fluid to be sealed, increases the deformation of the cross section of the seal ring and thus the pressure required for sealing (see Figure 2).

The simplicity of the geometry of the O-ring is the dominant feature of this sealing element. With a suitable choice of the quality of the elastomer and a precise definition of the cross section according to the size of the groove, the O-ring is an efficient, cost- effective and simple sealing system.

The installation spaces are calculated according to the criteria of the standard DIN 3771/5.

The inside diameter of the O-ring may, during the installation, be extended by 6% while the cross section can be compressed by 3 %.

In any given application it is always prudent to adopt the largest possible O-ring cross section in relation to the inside diameter d1 when selecting the cross section d2. It is particularly advisable to select the next larger cross section in connection with unfavorable tolerance conditions, in order to achieve a good sealing effect.

If elastomers come into contact with the media, they can absorb a certain proportion of these media. The capacity depends on the resistance of the elastomer material to the medium.The volume of the installation space must be designed so that the swelling and the thermal expansion due to a temperature increase can be absorbed.

A volumetric swelling was taken into account for the calculation of the width B1 of the housing.If in exceptional cases, a significant swelling is anticipated (8% dynamic sealing , 15% static sealing) the width B1 of the housing must be enlarged accordingly. A retraction should always be avoided.

Radial installation (static and dynamic), internal seal (rod seal)

The O-ring size should be selected so that the inside diameter d1 is at least equal to or larger than the outside diameter d5.

Radial installation (static and dynamic) external seal (piston seal)

The O-ring size should be selected so that the inside diameter d1 is equal to or smaller than groove diameter d3.

Axial, static installation

In axial static installations the pressure direction should be considered when selecting the O-ring.

These installation recommendations are only indications and are intended as approximate guidelines. Users are advised to perform tests validating the installation.

In the DIN 3771/5 standard, each O-ring inside diameter is assigned to a corresponding string section. This assignment should also be observed for the O-rings non-normalized because the degree of compression depends essentially on the tolerances of the cross section thickness and the groove.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent