Category

Photos are for informational purposes only. View product specification

please use latin characters

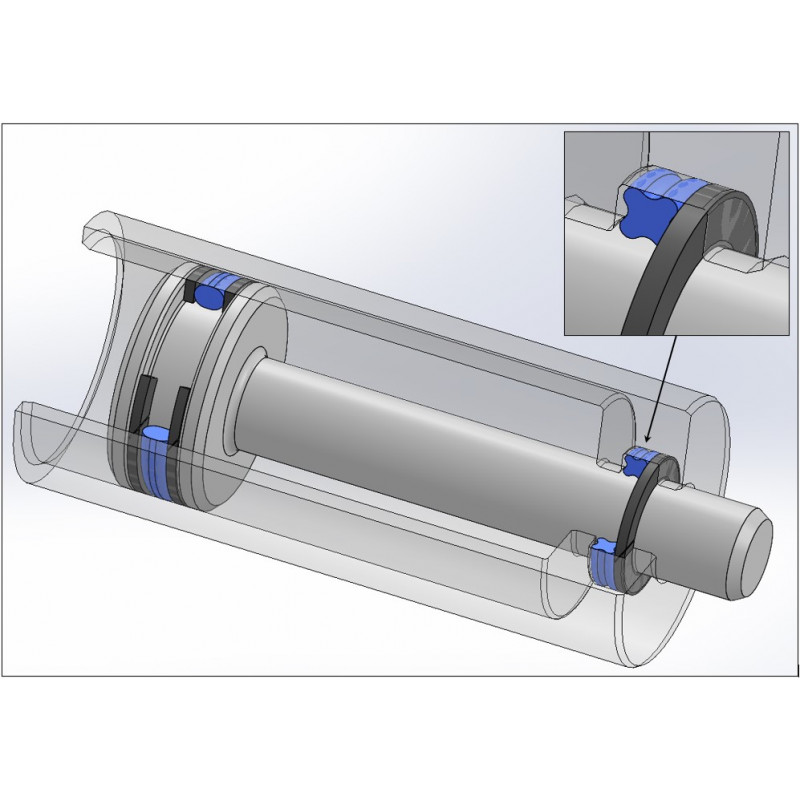

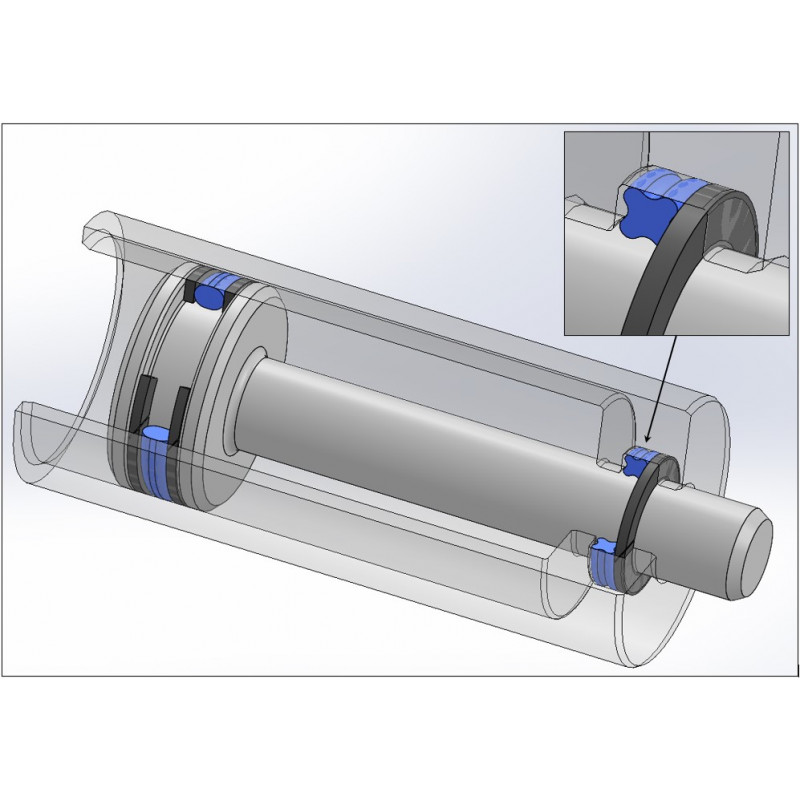

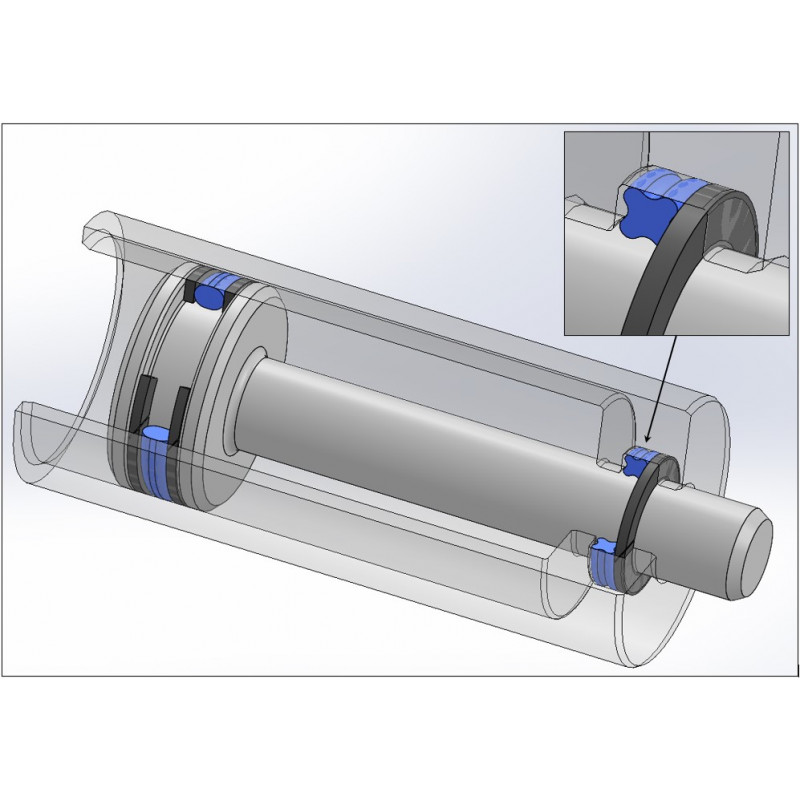

The Quad-ring is used primarily for dynamic sealing. Its field of application is limited by the respective pressure and speed. Quad-rings are self-sealing, double-acting sealing elements.

The recommended installation spaces are calculated according to the criteria of the standard AS568A. The expansion, deformation and reduction settings of the cross section and swelling are similar to those of the Orings. Compared to the method of assembly of O-rings, the assembly of the Quad-ring in a trapezoidal groove is not possible.

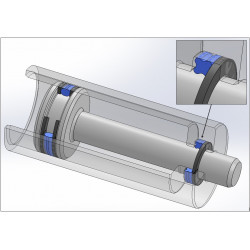

Quad-ring installation recommendation as rotary seal

For applications with short activity cycles, the Quad-ring can be used for sealing rotating shafts. It should be noted that the internal Quad-ring diameter selected should be approx. 2% - 5% greater than of that of the shaft requiring sealing. This is due to the fact that a stretched elastomer ring has been found to shrink under applied heat. This increases friction and wear, leading to a substantial reduction in service life. Under 0.5 m/s circumferential velocity, this proviso can however be neglected.

These installation recommendations are only indications and are intended as approximate guidelines. Users are advised to perform tests validating the installation.

| Pressure ranges* | Radial, axial static | Radial dynamic | Rotary dynamic |

|---|---|---|---|

| without back-up ring | 10 Mpa (100 bar) | 5 Mpa (50 bar) | 2,5 Mpa (25 bar) |

| with back-up ring | 40 Mpa (400 bar) | 30 Mpa (300 bar) | 15 Mpa (150 bar) |

| Speed | 0,5m/s | 2m/s (limited service) |

(*) take the allowed tolerances and the gap dimensions into account

Are you interested in this product? Do you need additional information or individual pricing?

The Quad-ring is used primarily for dynamic sealing. Its field of application is limited by the respective pressure and speed. Quad-rings are self-sealing, double-acting sealing elements.

The recommended installation spaces are calculated according to the criteria of the standard AS568A. The expansion, deformation and reduction settings of the cross section and swelling are similar to those of the Orings. Compared to the method of assembly of O-rings, the assembly of the Quad-ring in a trapezoidal groove is not possible.

Quad-ring installation recommendation as rotary seal

For applications with short activity cycles, the Quad-ring can be used for sealing rotating shafts. It should be noted that the internal Quad-ring diameter selected should be approx. 2% - 5% greater than of that of the shaft requiring sealing. This is due to the fact that a stretched elastomer ring has been found to shrink under applied heat. This increases friction and wear, leading to a substantial reduction in service life. Under 0.5 m/s circumferential velocity, this proviso can however be neglected.

These installation recommendations are only indications and are intended as approximate guidelines. Users are advised to perform tests validating the installation.

| Pressure ranges* | Radial, axial static | Radial dynamic | Rotary dynamic |

|---|---|---|---|

| without back-up ring | 10 Mpa (100 bar) | 5 Mpa (50 bar) | 2,5 Mpa (25 bar) |

| with back-up ring | 40 Mpa (400 bar) | 30 Mpa (300 bar) | 15 Mpa (150 bar) |

| Speed | 0,5m/s | 2m/s (limited service) |

(*) take the allowed tolerances and the gap dimensions into account

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent