-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

-

Recorders

- Hybrid Recorders - AL3000 Series | CHINO

- Graphic Recorder - KR2000 Series | CHINO

- Ubiquitous Recorders - KR5000 Series | CHINO

- Palm-sized Temperature/Humidity Meters - HN-CH Series | CHINO

- Consumables for Recorders

- 71VR1 - Compact Paperless Recorder | M-SYSTEM

- Graphic Recorder - KR3000 Series | CHINO

- PC Recorders - R1M Series | M-SYSTEM

- PC Recorders - R2M Series | M-SYSTEM

- PC Recorders - RZMS Series | M-SYSTEM

- PC Recorders - RZUS Series | M-SYSTEM

- Go to the subcategory

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- Galvanized and Stainless Steel Cylindrical Braids

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Hoses

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

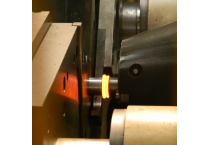

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Machines Repairs and Modernizations

Dacpol Service specializes in comprehensive renovations and modernizations of industrial machines and production lines.

Our qualified team of engineers, using modern tools and equipment, is capable of renovating most machines and devices used in the specialized...

Dacpol Service specializes in comprehensive renovations and modernizations of industrial machines and...

Dacpol Service specializes in comprehensive renovations and modernizations of industrial machines and production lines.

Our qualified team of engineers, using modern tools and equipment, is capable of renovating most machines and devices used in the specialized market.

By modernizing industrial machines, we can increase the efficiency of the device, improve the technology used in the device, and significantly extend its lifespan. Additionally, we adapt machines to new product lines by replacing components with modern solutions.

Repairs and Modernization of Industrial Machines

We offer professional repair and modernization services for industrial machines aimed at restoring and enhancing the efficiency and effectiveness of existing devices. Our knowledge and experience enable us to carry out repairs on most devices used in specialized manufacturing companies.

What Machines Do We Modernize?

Dacpol Service focuses on modernizing industrial devices such as:

- mechanical systems for the electrotechnical industry,

- pneumatic systems for automation and electrotechnics,

- industrial safety systems,

- automatic control systems,

- industrial robots and machines for transporting parts, grippers,

- control systems based on PLC controllers,

- control systems based on CNC control,

- drive systems,

- control cabinets and panels,

- generators and components for induction heating - induction coils, workstations.

List of Devices and Machines Modernized by Dacpol Service:

- mechanical systems for the electrotechnical industry;

- pneumatic systems for automation and electrotechnics;

- industrial safety systems;

- automatic control systems;

- industrial robots and machines for transporting parts, grippers;

- control systems based on PLC controllers;

- control systems based on CNC control;

- drive systems;

- control cabinets and panels;

- generators and components for induction heating - induction coils, workstations.

Why Choose Modernization of Industrial Machines?

Repair and modernization services for industrial machines increase their efficiency, which translates into increased production and profitability. Proper diagnosis and assessment of equipment condition, along with the implementation of appropriate solutions, restore machines to their original parameters, thus extending their lifespan. These actions streamline business operations and prevent downtimes on production lines while also leading to significant energy savings, reducing operational costs.

Modernization of machines is a necessary process and should be included in the action plan of every enterprise. Depending on the situation, repairs may involve replacing specific systems, outdated components, or even replacing worn parts with new ones. These actions improve the efficiency of the production department and the quality of services provided.

Need more information about the course and modernization of industrial machines in our company? Contact us. Our specialists are available for professional advice and assistance - they will present a detailed action plan for the given situation and tailor it to your needs.

Also check our industrial refrigeration service

Related posts