Category

Photos are for informational purposes only. View product specification

please use latin characters

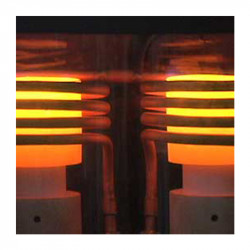

Brazing in a controlled vacuum or in an inert protective atmosphere can significantly improve overall part quality and eliminate costly part cleaning procedures.

Flame heating in a normal oxygen atmosphere can cause oxidation, scaling and carbon buildup on the parts. To clean the parts, applications of joint weakening flux or expensive acid cleaning baths are often required.

The nature of the parts and brazing material dictates whether an inert gas such as argon or a true atmospheric vacuum should be used. Atmospheric brazing is often used with nickel, titanium, superalloys, stainless steel and refractories.

A protective atmosphere heating system with an induction heating RF power supply is ideal for atmospheric brazing. Batch vacuum furnaces can also be used, but they have significant limitations because of their large size, poor efficiency and lack of quality control.

Typical RF power supplies for atmospheric brazing range from 1 to 20kW, depending on the parts and application requirements.

Are you interested in this product? Do you need additional information or individual pricing?

Brazing in a controlled vacuum or in an inert protective atmosphere can significantly improve overall part quality and eliminate costly part cleaning procedures.

Flame heating in a normal oxygen atmosphere can cause oxidation, scaling and carbon buildup on the parts. To clean the parts, applications of joint weakening flux or expensive acid cleaning baths are often required.

The nature of the parts and brazing material dictates whether an inert gas such as argon or a true atmospheric vacuum should be used. Atmospheric brazing is often used with nickel, titanium, superalloys, stainless steel and refractories.

A protective atmosphere heating system with an induction heating RF power supply is ideal for atmospheric brazing. Batch vacuum furnaces can also be used, but they have significant limitations because of their large size, poor efficiency and lack of quality control.

Typical RF power supplies for atmospheric brazing range from 1 to 20kW, depending on the parts and application requirements.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent