Category

Photos are for informational purposes only. View product specification

please use latin characters

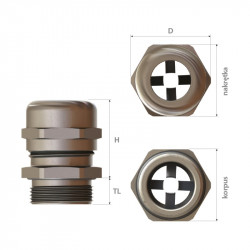

| These EMC cable glands combine several advantages in one product. First, you get the same clamping ranges as the standard brass glands. The protection class is IP68. In order to get a low electrical impedance between the cable gland and the braiding of the cable the cable gland does not have to be disassembled. Secondly, a perfect shielding will be achieved by just tightening the dome nut. This high tech cable gland consists of a nickel plated brass body, PA6 clamping insert, an EMC contact element and choloprene seal. The components are pre-assembled. |

|

|

| Material | Body | Brass, nickel plated | |

|---|---|---|---|

| Cap | Brass, nickel plated | ||

| Seal | CR (chloroprene rubber) | ||

| Clamping insert | PA 6 (polyamide 6) | ||

| Contact spring | Special copper alloy | ||

| O-ring | NBR | ||

| Protection class | IP68 - 5 Bar, 30 min | ||

| Flammability | UL94 V-2 | ||

| Operating temperature | Permanent | Intermittent | |

| -20°C ÷ +100°C | -40°C ÷ +150°C | ||

| Thread type |

|

||

| Cable type | Non armoured, shielded | ||

| Accessories |

|

||

| Remarks |

|

||

| Size | Clamping range | Shield diameter | Thread lenght | Thread ∅ | Spanner width | Outer ∅ | Max. height | Part Number | Packing unit | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Outer seal ∅ min - max [mm] | Double seal ∅ min - max [mm] | ∅ min - max [mm] | TL [mm] | TD [mm] | SW Cap [mm] | SW Body [mm] | D [mm] | H [mm] | |||

| M12x1,5 | 3,0 - 6,5 | 2,5 | 6,0 | 12,0 | 14 | 14 | 15,5 | 22,0 | BMEM-0S | 50 | |

| 12,0 | BMEN-0S | ||||||||||

| M16x1,5 | 4,0 - 8,0 | 3,0 | 7,0 | 16,0 | 17 | 18 | 20,0 | 23,0 | BMEM-01 | 50 | |

| 12,0 | BMEN-01 | ||||||||||

| 4,5 - 10,0 | 3,5 | 6,5 | 20 | 20 | 22,0 | 29,0 | BMEM-01S | ||||

| M20x1,5 | 6,0 - 12,0 | 4,5 | 8,0 | 20,0 | 22 | 22 | 24,5 | 24,5 | BMEM-02 | 50 | |

| 12,0 | BMEN-02 | ||||||||||

| M25x1,5 | 10,0 - 14,0 | 8,5 | 8,0 | 25,0 | 24 | 27 | 29,8 | 28,0 | BMEM-03 | 25 | |

| 12,0 | BMEN-03 | ||||||||||

| 13,0 - 18,0 | 10,5 | 8,0 | 30 | 30 | 33,0 | 37,5 | BMEM-03S | ||||

| M32x1,5 | 13,0 - 18,0 | 11,0 | 9,0 | 32,0 | 30 | 34 | 37,5 | 32,5 | BMEM-04 | 25 | |

| 15,0 | BMEN-04 | ||||||||||

| 18,0 - 25,0 | 14,0 | 9,0 | 40 | 40 | 44,5 | 44,0 | BMEM-04S | ||||

| M40x1,5 | 18,0 - 25,0 | 16,0 | 9,0 | 40,0 | 40 | 43 | 48,5 | 38,0 | BMEM-05 | 20 | |

| 15,0 | BMEN-05 | ||||||||||

| 22,0 - 32,0 | 20,0 | 9,0 | 50 | 50 | 55,5 | 52,5 | BMEM-05S | ||||

| M50x1,5 | 22,0 - 32,0 | 20,0 | 9,0 | 50,0 | 50 | 55 | 61,0 | 48,0 | BMEM-06 | 15 | |

| 15,0 | BMEN-06 | ||||||||||

| 34,0 - 44,0 | 27,0 - 35,0 | 26,0 | 9,0 | 64 | 68 | 70,0 | 54,0 | BMEM-06S | 10 | ||

| M63x1,5 | 34,0 - 44,0 | 31,0 | 14,0 | 63,0 | 64 | 68 | 75,0 | 53,0 | BMEM-07 | 12 | |

| 18,0 | BMEN-07 | ||||||||||

| Size | Clamping range ∅ min - max | Shield diameter ∅ min - max | Thread lenght TL | Thread ∅ TD | Spanner width | Outer ∅ D | Max. height H | Part number | Packing unit | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [mm] | [in] | [mm] | [in] | [mm] | [in] | [mm] | [in] | SW Cap | SW Body | [mm] | [in] | [mm] | [in] | |||||

| [mm] | [in] | [mm] | [in] | |||||||||||||||

| NPT 3/8" | 5,0 - 10,0 | 0.197 - 0.394 | 4,0 | 0.157 | 11,5 | 0.453 | 17,14 | 0.675 | 20 | 0.787 | 20 | 0.787 | 22,0 | 0.866 | 29,5 | 1.161 | BNEM-01 | 50 |

| NPT 1/2" | 6,0 - 12,0 | 0.236 - 0.472 | 5,0 | 0.197 | 13,0 | 0.512 | 21,34 | 0.840 | 22 | 0.866 | 22 | 0.866 | 24,5 | 0.965 | 25,5 | 1.004 | BNEM-02 | 50 |

| NPT 3/4" | 13,0 - 18,0 | 0.512 - 0.709 | 11,0 | 0.433 | 13,0 | 0.512 | 26,67 | 1.050 | 30 | 1.181 | 30 | 1.181 | 33,0 | 1.299 | 35,5 | 1.398 | BNEM-03 | 25 |

| NPT 1" | 18,0 - 25,0 | 0.709 - 0.984 | 16,0 | 0.630 | 13,0 | 0.512 | 33,40 | 1.315 | 40 | 1.575 | 43 | 1.693 | 48,5 | 1.909 | 43,0 | 1.693 | BNEM-04 | 10 |

| Size | Clamping range ∅ min - max [mm] | Shield diameter ∅ min - max [mm] | Thread lenght TL [mm] | Thread ∅ TD [mm] | Spanner width | Outer ∅ D [mm] | Max. height H [mm] | Part number | Packing unit | |

|---|---|---|---|---|---|---|---|---|---|---|

| SW Cap [mm] | SW Body [mm] | |||||||||

| PG 7 | 3,0 - 6,5 | 2,5 | 6,0 | 12,5 | 14 | 14 | 15,5 | 22,0 | BSEM-01 | 50 |

| 8,0 | BSEN-01 | |||||||||

| PG 9 | 4,0 - 8,0 | 3,0 | 6,0 | 15,2 | 17 | 17 | 18,9 | 23,2 | BSEM-02 | 50 |

| 10,0 | BSEN-02 | |||||||||

| PG 11 | 5,0 - 10,0 | 4,0 | 6,0 | 18,6 | 20 | 20 | 22,0 | 26,0 | BSEM-03 | 50 |

| 10,0 | BSEN-03 | |||||||||

| PG 13,5 | 6,0 - 12,0 | 5,0 | 6,5 | 20,4 | 22 | 22 | 24,5 | 24,5 | BSEM-04 | 50 |

| 10,0 | BSEN-04 | |||||||||

| PG 16 | 10,0 - 14,0 | 8,5 | 6,5 | 22,5 | 24 | 24 | 26,5 | 28,0 | BSEM-05 | 25 |

| 10,0 | BSEN-05 | |||||||||

| PG 21 | 13,0 - 18,0 | 11,0 | 7,2 | 28,3 | 30 | 30 | 33,0 | 32,5 | BSEM-06 | 25 |

| 12,0 | BSEN-06 | |||||||||

| PG 29 | 18,0 - 25,0 | 16,0 | 8,0 | 37,0 | 40 | 40 | 44,5 | 38,0 | BSEM-07 | 20 |

| 12,0 | BSEN-07 | |||||||||

| PG 36 | 22,0 - 32,0 | 20,0 | 9,0 | 47,0 | 50 | 50 | 55,5 | 48,0 | BSEM-08 | 15 |

| 14,0 | BSEN-08 | |||||||||

| PG 42 | 30,0 - 38,0 | 28,0 | 12,0 | 54,0 | 58 | 58 | 64,0 | 48,0 | BSEM-09 | 12 |

| 16,0 | BSEN-09 | |||||||||

| PG 48 | 34,0 - 44,0 | 31,0 | 14,0 | 59,3 | 64 | 64 | 70,0 | 52,4 | BSEM-10 | 12 |

| 18,0 | BSEN-10 | |||||||||

Are you interested in this product? Do you need additional information or individual pricing?

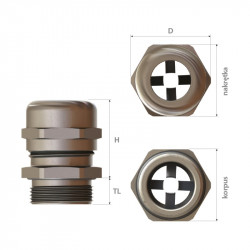

| These EMC cable glands combine several advantages in one product. First, you get the same clamping ranges as the standard brass glands. The protection class is IP68. In order to get a low electrical impedance between the cable gland and the braiding of the cable the cable gland does not have to be disassembled. Secondly, a perfect shielding will be achieved by just tightening the dome nut. This high tech cable gland consists of a nickel plated brass body, PA6 clamping insert, an EMC contact element and choloprene seal. The components are pre-assembled. |

|

|

| Material | Body | Brass, nickel plated | |

|---|---|---|---|

| Cap | Brass, nickel plated | ||

| Seal | CR (chloroprene rubber) | ||

| Clamping insert | PA 6 (polyamide 6) | ||

| Contact spring | Special copper alloy | ||

| O-ring | NBR | ||

| Protection class | IP68 - 5 Bar, 30 min | ||

| Flammability | UL94 V-2 | ||

| Operating temperature | Permanent | Intermittent | |

| -20°C ÷ +100°C | -40°C ÷ +150°C | ||

| Thread type |

|

||

| Cable type | Non armoured, shielded | ||

| Accessories |

|

||

| Remarks |

|

||

| Size | Clamping range | Shield diameter | Thread lenght | Thread ∅ | Spanner width | Outer ∅ | Max. height | Part Number | Packing unit | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Outer seal ∅ min - max [mm] | Double seal ∅ min - max [mm] | ∅ min - max [mm] | TL [mm] | TD [mm] | SW Cap [mm] | SW Body [mm] | D [mm] | H [mm] | |||

| M12x1,5 | 3,0 - 6,5 | 2,5 | 6,0 | 12,0 | 14 | 14 | 15,5 | 22,0 | BMEM-0S | 50 | |

| 12,0 | BMEN-0S | ||||||||||

| M16x1,5 | 4,0 - 8,0 | 3,0 | 7,0 | 16,0 | 17 | 18 | 20,0 | 23,0 | BMEM-01 | 50 | |

| 12,0 | BMEN-01 | ||||||||||

| 4,5 - 10,0 | 3,5 | 6,5 | 20 | 20 | 22,0 | 29,0 | BMEM-01S | ||||

| M20x1,5 | 6,0 - 12,0 | 4,5 | 8,0 | 20,0 | 22 | 22 | 24,5 | 24,5 | BMEM-02 | 50 | |

| 12,0 | BMEN-02 | ||||||||||

| M25x1,5 | 10,0 - 14,0 | 8,5 | 8,0 | 25,0 | 24 | 27 | 29,8 | 28,0 | BMEM-03 | 25 | |

| 12,0 | BMEN-03 | ||||||||||

| 13,0 - 18,0 | 10,5 | 8,0 | 30 | 30 | 33,0 | 37,5 | BMEM-03S | ||||

| M32x1,5 | 13,0 - 18,0 | 11,0 | 9,0 | 32,0 | 30 | 34 | 37,5 | 32,5 | BMEM-04 | 25 | |

| 15,0 | BMEN-04 | ||||||||||

| 18,0 - 25,0 | 14,0 | 9,0 | 40 | 40 | 44,5 | 44,0 | BMEM-04S | ||||

| M40x1,5 | 18,0 - 25,0 | 16,0 | 9,0 | 40,0 | 40 | 43 | 48,5 | 38,0 | BMEM-05 | 20 | |

| 15,0 | BMEN-05 | ||||||||||

| 22,0 - 32,0 | 20,0 | 9,0 | 50 | 50 | 55,5 | 52,5 | BMEM-05S | ||||

| M50x1,5 | 22,0 - 32,0 | 20,0 | 9,0 | 50,0 | 50 | 55 | 61,0 | 48,0 | BMEM-06 | 15 | |

| 15,0 | BMEN-06 | ||||||||||

| 34,0 - 44,0 | 27,0 - 35,0 | 26,0 | 9,0 | 64 | 68 | 70,0 | 54,0 | BMEM-06S | 10 | ||

| M63x1,5 | 34,0 - 44,0 | 31,0 | 14,0 | 63,0 | 64 | 68 | 75,0 | 53,0 | BMEM-07 | 12 | |

| 18,0 | BMEN-07 | ||||||||||

| Size | Clamping range ∅ min - max | Shield diameter ∅ min - max | Thread lenght TL | Thread ∅ TD | Spanner width | Outer ∅ D | Max. height H | Part number | Packing unit | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [mm] | [in] | [mm] | [in] | [mm] | [in] | [mm] | [in] | SW Cap | SW Body | [mm] | [in] | [mm] | [in] | |||||

| [mm] | [in] | [mm] | [in] | |||||||||||||||

| NPT 3/8" | 5,0 - 10,0 | 0.197 - 0.394 | 4,0 | 0.157 | 11,5 | 0.453 | 17,14 | 0.675 | 20 | 0.787 | 20 | 0.787 | 22,0 | 0.866 | 29,5 | 1.161 | BNEM-01 | 50 |

| NPT 1/2" | 6,0 - 12,0 | 0.236 - 0.472 | 5,0 | 0.197 | 13,0 | 0.512 | 21,34 | 0.840 | 22 | 0.866 | 22 | 0.866 | 24,5 | 0.965 | 25,5 | 1.004 | BNEM-02 | 50 |

| NPT 3/4" | 13,0 - 18,0 | 0.512 - 0.709 | 11,0 | 0.433 | 13,0 | 0.512 | 26,67 | 1.050 | 30 | 1.181 | 30 | 1.181 | 33,0 | 1.299 | 35,5 | 1.398 | BNEM-03 | 25 |

| NPT 1" | 18,0 - 25,0 | 0.709 - 0.984 | 16,0 | 0.630 | 13,0 | 0.512 | 33,40 | 1.315 | 40 | 1.575 | 43 | 1.693 | 48,5 | 1.909 | 43,0 | 1.693 | BNEM-04 | 10 |

| Size | Clamping range ∅ min - max [mm] | Shield diameter ∅ min - max [mm] | Thread lenght TL [mm] | Thread ∅ TD [mm] | Spanner width | Outer ∅ D [mm] | Max. height H [mm] | Part number | Packing unit | |

|---|---|---|---|---|---|---|---|---|---|---|

| SW Cap [mm] | SW Body [mm] | |||||||||

| PG 7 | 3,0 - 6,5 | 2,5 | 6,0 | 12,5 | 14 | 14 | 15,5 | 22,0 | BSEM-01 | 50 |

| 8,0 | BSEN-01 | |||||||||

| PG 9 | 4,0 - 8,0 | 3,0 | 6,0 | 15,2 | 17 | 17 | 18,9 | 23,2 | BSEM-02 | 50 |

| 10,0 | BSEN-02 | |||||||||

| PG 11 | 5,0 - 10,0 | 4,0 | 6,0 | 18,6 | 20 | 20 | 22,0 | 26,0 | BSEM-03 | 50 |

| 10,0 | BSEN-03 | |||||||||

| PG 13,5 | 6,0 - 12,0 | 5,0 | 6,5 | 20,4 | 22 | 22 | 24,5 | 24,5 | BSEM-04 | 50 |

| 10,0 | BSEN-04 | |||||||||

| PG 16 | 10,0 - 14,0 | 8,5 | 6,5 | 22,5 | 24 | 24 | 26,5 | 28,0 | BSEM-05 | 25 |

| 10,0 | BSEN-05 | |||||||||

| PG 21 | 13,0 - 18,0 | 11,0 | 7,2 | 28,3 | 30 | 30 | 33,0 | 32,5 | BSEM-06 | 25 |

| 12,0 | BSEN-06 | |||||||||

| PG 29 | 18,0 - 25,0 | 16,0 | 8,0 | 37,0 | 40 | 40 | 44,5 | 38,0 | BSEM-07 | 20 |

| 12,0 | BSEN-07 | |||||||||

| PG 36 | 22,0 - 32,0 | 20,0 | 9,0 | 47,0 | 50 | 50 | 55,5 | 48,0 | BSEM-08 | 15 |

| 14,0 | BSEN-08 | |||||||||

| PG 42 | 30,0 - 38,0 | 28,0 | 12,0 | 54,0 | 58 | 58 | 64,0 | 48,0 | BSEM-09 | 12 |

| 16,0 | BSEN-09 | |||||||||

| PG 48 | 34,0 - 44,0 | 31,0 | 14,0 | 59,3 | 64 | 64 | 70,0 | 52,4 | BSEM-10 | 12 |

| 18,0 | BSEN-10 | |||||||||

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent