Category

Photos are for informational purposes only. View product specification

please use latin characters

Universal, rail-mounted, NFC-compatible PID controller

Technical Specification

Before the system's first operation, if the PID parameters are known, they should be entered; otherwise, the self-tuning function should be activated.

Technical Data

| Parameter | Value |

| Power Supply | 24V DC |

| Maximum Power Consumption | 5VA |

| Connection | 1.5mm2 screw terminal |

| Maximum Terminal Connection Resistance | 100Ω for thermocouple, 20Ω for three-wire PT100 |

| Ambient/Storage Temperature | 0…+50°C/-25…+70°C (non-condensing) |

| Protection Class | Compliant with EN 60529 IP20 |

| Hysteresis | Adjustable range 1…50°C/F |

Inputs

| Parameter | Value |

| Power Supply | 24V DC |

| Maximum Power Consumption | 5VA |

| Connection | 1.5mm2 screw terminal |

| Maximum Terminal Connection Resistance | 100Ω for thermocouple, 20Ω for three-wire PT100 |

| Ambient/Storage Temperature | 0…+50°C / -25…+70°C (non-condensing) |

| Protection Class | Compliant with EN 60529 IP20 |

| Hysteresis | Adjustable range 1…50°C/F |

Inputs

| Universal sensor inputs | See Sensor Inputs table (rows 1-3) | |

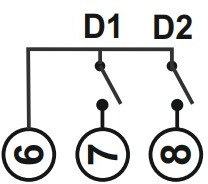

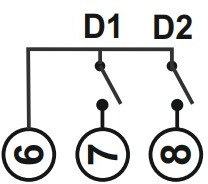

| Potential-free contact input D1 | Programmable input 1 for control button | See Sensor Inputs table (row 4) |

| Potential-free contact input D2 | Programmable input 2 for control button | See Sensor Inputs table (row 4) |

Outputs

| Output C/A2 | Relay: 250 V AC, 5 A (for resistive load), NO (control or Alarm2 output selection) |

| Output A1 | Relay: 250 V AC, 5 A (for resistive load), NO control |

| ANL/SSR outputs | Selectable analog output 0-20mA and 4-20mA; SSR 15V 20mA Maximum load resistance is 500Ω on mA output and in SSR mode |

| Relay lifetime | 10,000,000 operations without load; 250 V AC, 5 A (resistive load) 300,000 operations |

Housing

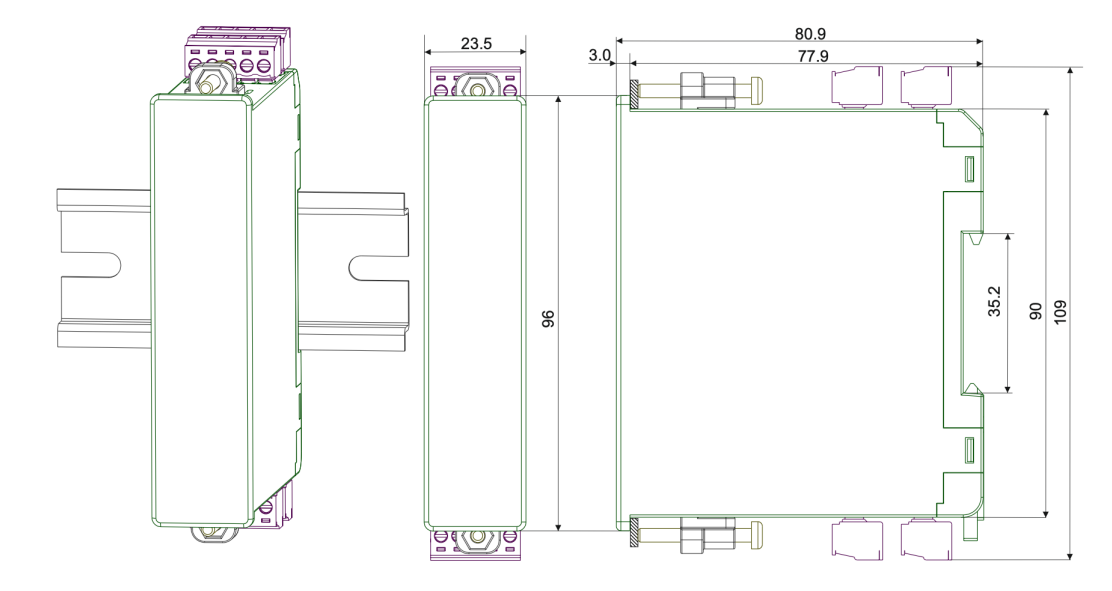

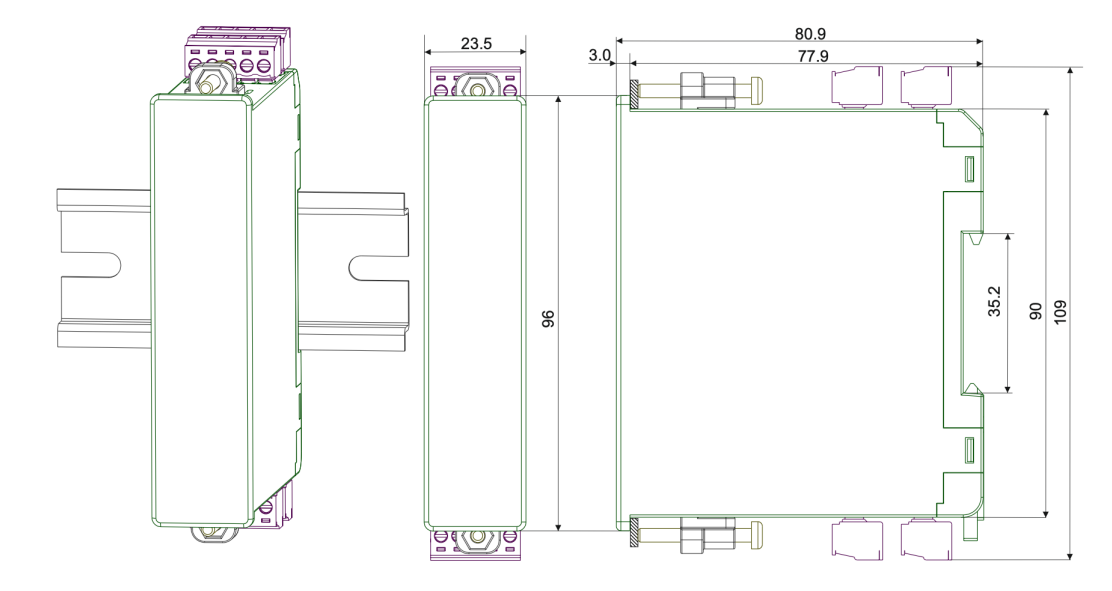

| Housing type | DIN rail-mounted housing compliant with DIN 43 700 |

| Dimensions (width x height x depth) | 22.5 x 96 x 86 mm |

| Weight | approx. 158 g (packed) |

| Housing material | Self-extinguishing plastic |

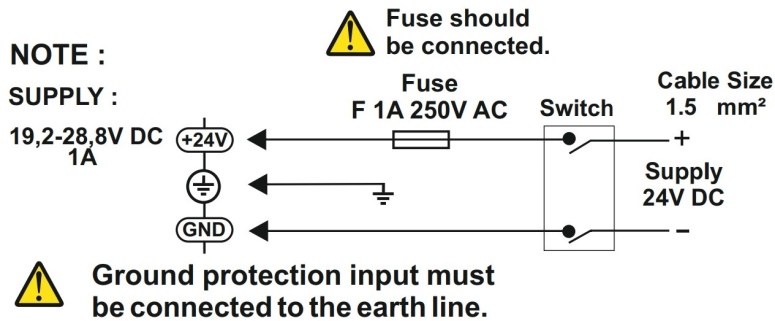

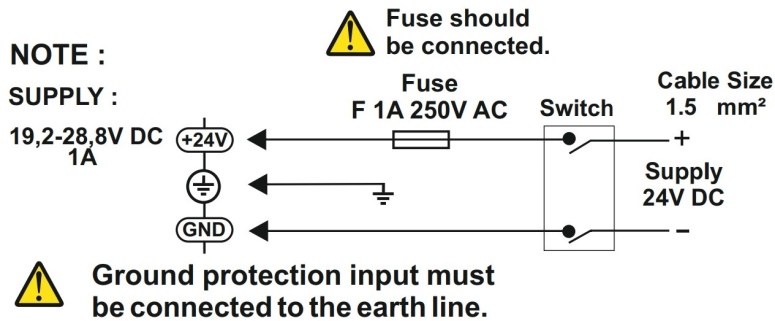

Wiring Diagram

Translation:

Note – Uwaga

Supply – Zasilanie

Fuse should be connected. – Bezpiecznik powinien być podłączony.

Fuse – bezpiecznik

Switch – przełącznik

Cable size – rozmiar przewodu

Ground protection input must be connected to the earth line. – Wejście uziemiające musi być podłączone do linii uziemienia.

|

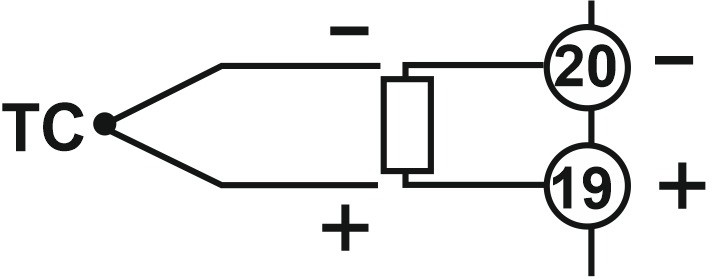

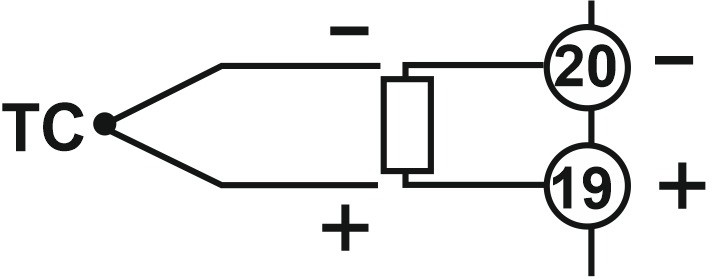

• Thermocouples type J-K-L-T-S-R: Use appropriate compensation cables for thermocouples. Do not use jointed cables. Ensure input terminals are connected correctly with proper polarity as shown in the figure. |

|

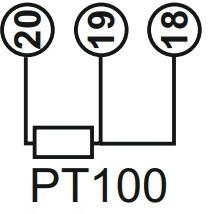

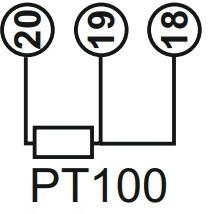

• Resistance (Pt100) thermocouples: For two-wire PT100 sensors, short-circuit terminals 2 and 3. Do not use jointed cables. Long cables cause incorrect temperature measurement. |

|

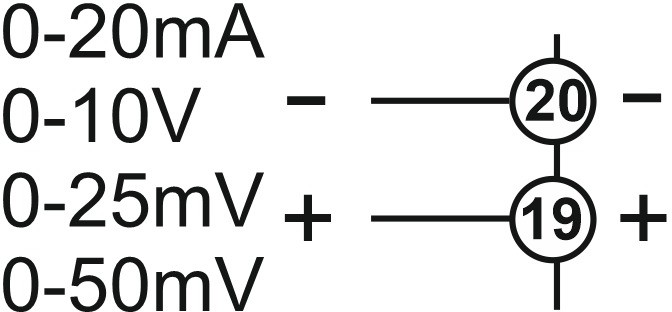

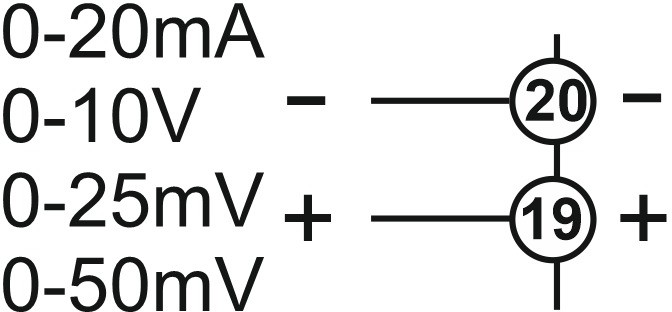

• Inputs: 0-20mA, 4-20mA, 0-10V, 2-10V, 0-25mV, 0-50mV: Ensure correct connection and proper polarity at the input terminals as shown in the figure. Do not use jointed cables. Long cables cause incorrect measurement results. |

|

• Potential-free contact inputs D1 and D2: Potential-free contacts must be used with mechanical keys. |

Dimensions (in mm)

Controller Programming

The controller can be programmed via the ENDALink application by bringing a phone with NFC function close. All parameters can be read and configured in the application. A detailed description of the parameters is in the catalog note. QR codes for scanning and installing the application:

Are you interested in this product? Do you need additional information or individual pricing?

Universal, rail-mounted, NFC-compatible PID controller

Technical Specification

Before the system's first operation, if the PID parameters are known, they should be entered; otherwise, the self-tuning function should be activated.

Technical Data

| Parameter | Value |

| Power Supply | 24V DC |

| Maximum Power Consumption | 5VA |

| Connection | 1.5mm2 screw terminal |

| Maximum Terminal Connection Resistance | 100Ω for thermocouple, 20Ω for three-wire PT100 |

| Ambient/Storage Temperature | 0…+50°C/-25…+70°C (non-condensing) |

| Protection Class | Compliant with EN 60529 IP20 |

| Hysteresis | Adjustable range 1…50°C/F |

Inputs

| Parameter | Value |

| Power Supply | 24V DC |

| Maximum Power Consumption | 5VA |

| Connection | 1.5mm2 screw terminal |

| Maximum Terminal Connection Resistance | 100Ω for thermocouple, 20Ω for three-wire PT100 |

| Ambient/Storage Temperature | 0…+50°C / -25…+70°C (non-condensing) |

| Protection Class | Compliant with EN 60529 IP20 |

| Hysteresis | Adjustable range 1…50°C/F |

Inputs

| Universal sensor inputs | See Sensor Inputs table (rows 1-3) | |

| Potential-free contact input D1 | Programmable input 1 for control button | See Sensor Inputs table (row 4) |

| Potential-free contact input D2 | Programmable input 2 for control button | See Sensor Inputs table (row 4) |

Outputs

| Output C/A2 | Relay: 250 V AC, 5 A (for resistive load), NO (control or Alarm2 output selection) |

| Output A1 | Relay: 250 V AC, 5 A (for resistive load), NO control |

| ANL/SSR outputs | Selectable analog output 0-20mA and 4-20mA; SSR 15V 20mA Maximum load resistance is 500Ω on mA output and in SSR mode |

| Relay lifetime | 10,000,000 operations without load; 250 V AC, 5 A (resistive load) 300,000 operations |

Housing

| Housing type | DIN rail-mounted housing compliant with DIN 43 700 |

| Dimensions (width x height x depth) | 22.5 x 96 x 86 mm |

| Weight | approx. 158 g (packed) |

| Housing material | Self-extinguishing plastic |

Wiring Diagram

Translation:

Note – Uwaga

Supply – Zasilanie

Fuse should be connected. – Bezpiecznik powinien być podłączony.

Fuse – bezpiecznik

Switch – przełącznik

Cable size – rozmiar przewodu

Ground protection input must be connected to the earth line. – Wejście uziemiające musi być podłączone do linii uziemienia.

|

• Thermocouples type J-K-L-T-S-R: Use appropriate compensation cables for thermocouples. Do not use jointed cables. Ensure input terminals are connected correctly with proper polarity as shown in the figure. |

|

• Resistance (Pt100) thermocouples: For two-wire PT100 sensors, short-circuit terminals 2 and 3. Do not use jointed cables. Long cables cause incorrect temperature measurement. |

|

• Inputs: 0-20mA, 4-20mA, 0-10V, 2-10V, 0-25mV, 0-50mV: Ensure correct connection and proper polarity at the input terminals as shown in the figure. Do not use jointed cables. Long cables cause incorrect measurement results. |

|

• Potential-free contact inputs D1 and D2: Potential-free contacts must be used with mechanical keys. |

Dimensions (in mm)

Controller Programming

The controller can be programmed via the ENDALink application by bringing a phone with NFC function close. All parameters can be read and configured in the application. A detailed description of the parameters is in the catalog note. QR codes for scanning and installing the application:

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent