Ferrite Cores

Categories

- EI Cores

- E Cores & Accessories

- Planar E Cores & Accessories

- EC Cores & Accessories

- EFD Cores & Accessories

- EP Cores & Accessories

- EPX Cores & Accessories

- EQ Cores & Accessories

- ER Cores

- Planar ER Cores & Accessories

- ETD Cores & Accessories

- Frame and Bar Cores & Accessories

- P, P/I Cores & Accessories

- PT, PTS Cores & Accessories

- PH Cores

- PM Cores

- PQ Cores & Accessories

- RM, RM/I & RM/ILP Cores & Accessories

- U, I Cores & Accessories

- Ferrite Toroids (ring cores)

- Gapped Ferrite Toroids (ring cores)

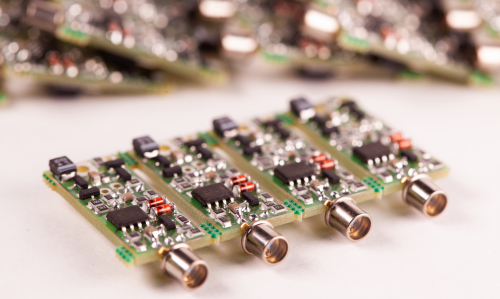

Ferrite Cores for Chokes, Transformers, Coils, and EMC Components

Ferrite core as inductors are elements made from a material classified as refractory ceramics, created from iron oxide with the addition of oxides of other metals, such as zinc, manganese, or nickel. It is commonly used in electronic devices because it exhibits the ability to suppress electromagnetic interference and has low energy losses at high frequencies.

What are ferrite cores used for?

Ferrite core concentrates and directs magnetic fields in electrical circuits. The current flowing through the conductor generates a magnetic field around it, which is concentrated in them due to their high magnetic permeability. As a result, the circuit's efficiency is increased.

Such operation makes the ferrite core perform several functions. Primarily, it increases inductance in coils and transformers, enabling them to operate at higher frequencies without significant power losses.

In addition, ferrite cores are highly effective in suppressing interference from high-frequency signals, such as electromagnetic interference (EMI). They act as ferrite filters, increasing inductive resistance for them, thereby weakening or completely eliminating EMI.

How are ferrite cores made?

Ferrite cores are produced using the same processes as other ceramic components. First, the material in powder form is pressed into the desired shape, then dried and fired. The resulting ferrite core is characterized by high hardness and brittleness. These properties make it sensitive to impacts, shocks, and other mechanical damage, and it cannot be processed after production. Therefore, these components are available in the DACPOL range in many variants, both in terms of shapes and types, allowing for proper selection for specific applications.

Basic types of ferrite cores

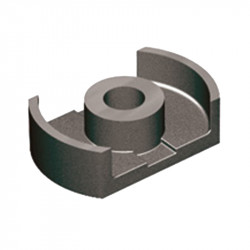

The ferrite cores available at DACPOL are most commonly used in the E version. They are used in the production of transformers, switching power supplies, power chokes, and anti-interference chokes. They feature three columns, with the central one wrapped with a conductor, which forms the main path for the magnetic flux. Their subtypes include, among others, EFD ferrite cores with a low profile, used in transformers designed for high-frequency operation, as well as ETD with a round central column. In addition to these, other versions include:

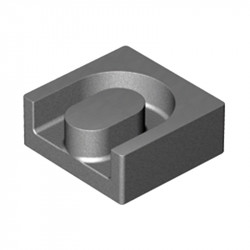

- PQ, characterized by a compact and enclosed design, equipped with a round central column. They are used, among others, in AC/DC and DC/AC converters.

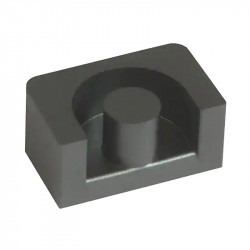

- RM, with a round central column and an enclosed form. Providing low interference emission while maintaining a high fill factor. Used in the production of chokes and transformers in switching power supplies. Also used in resonant circuits.

- UU and UI, with two columns and regular shapes. Mainly used in anti-interference filters, current-compensated chokes, and transformers,

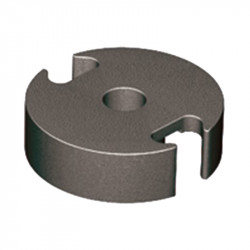

- P, due to their round shape, referred to as cup cores, featuring excellent magnetic shielding. Used in broadband transformers, pulse transformers, and resonant circuits.

A special type of core is the ferrite rings R, which are characterized by a toroidal shape and a closed magnetic circuit. They have low stray inductance, making them suitable for pulse transformers and anti-interference chokes. Additionally, at DACPOL, you can also order ferrite cores made according to your own design, both in terms of shape and material from which they will be produced.