Category

Photos are for informational purposes only. View product specification

please use latin characters

The SC series consists of vibration level sensors with tuning fork elements that use piezoelectric crystals and semiconductor electronics technology to generate vibrations in the tuning fork element at a specific frequency and receive electronic feedback. When the probe element makes contact with the target material, the vibrations are dampened, and the electronic feedback changes, with the presence of the material being detected by the electronics, which changes the sensor output state, indicating the presence of the material. When the probe element no longer makes contact with the target material, vibrations are generated again, and the output state returns to indicating the absence of the material.

Main features:

Applications:

The device is used for detecting the maximum and minimum levels of tanks or pipes filled with various solid/liquid materials. Examples of substances that can be monitored:

Industries where sensors can be used:

Technical Data:

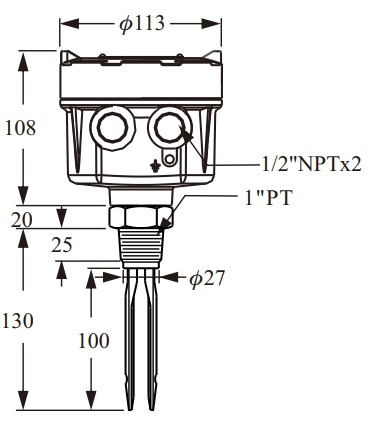

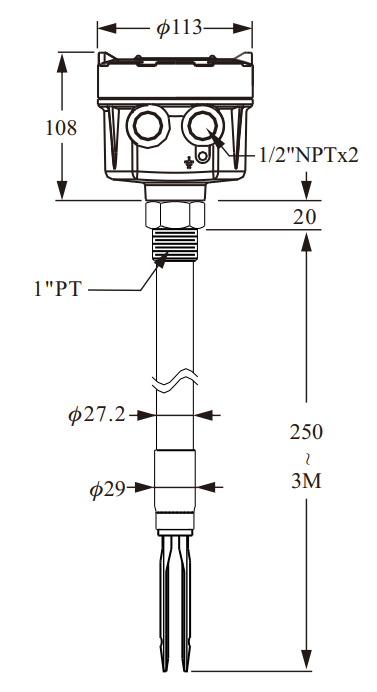

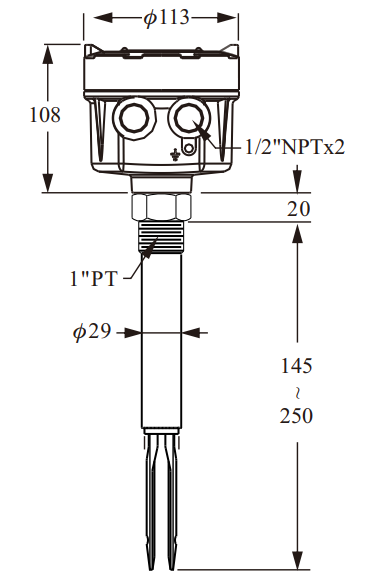

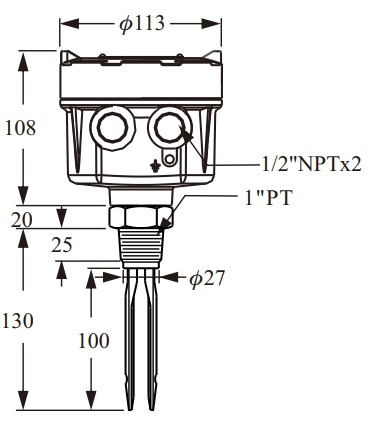

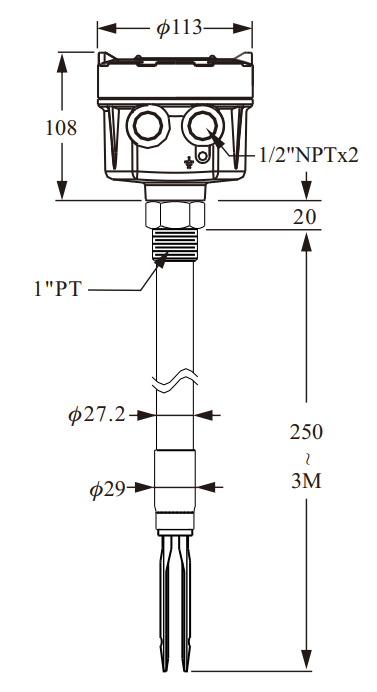

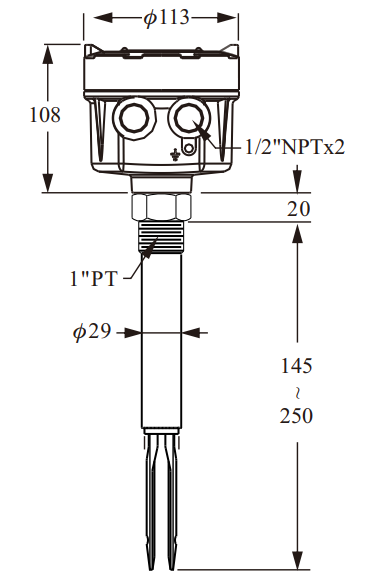

| Dimensions [mm] |  |

|

|

|---|---|---|---|

| Model | SC1400 Standard | SC1410 with Extra Long Tuning Forks | SC1420 with Long Tuning Forks |

| Level Sensor Housing | Aluminum / IP65 | ||

| Sensor Material | SUS 304 / 316 / 316L | ||

| Mounting | 1”PT | ||

| Connector | ½”NPT x 2 | ||

| Maximum Vertical Rod Load | 20Nm | ||

| Process Pressure | 40 bar | ||

| Power Supply Voltage | 20…250V AC/DC 50/60Hz | ||

| Power Consumption | 10VA | ||

| Ambient Temperature | -40…60°C | ||

| Process Temperature | -40…130°C | ||

| Output Signal | Relay, SPDT, 5A/250V AC, 1 or 2 sets of SSR (MOSFET) 400mA/60V AC/DC, 1 or 2 sets | ||

| Minimum Detectable Material Density | Solid: ≥0.07g/cm³, Liquid: ≥0.7g/cm³ | ||

| Time Delay | 0.6s / Operation; 1-3s / Reset | ||

| Vibration Frequency | 350-370Hz | ||

| Selectable Sensitivity | High / Low | ||

Are you interested in this product? Do you need additional information or individual pricing?

The SC series consists of vibration level sensors with tuning fork elements that use piezoelectric crystals and semiconductor electronics technology to generate vibrations in the tuning fork element at a specific frequency and receive electronic feedback. When the probe element makes contact with the target material, the vibrations are dampened, and the electronic feedback changes, with the presence of the material being detected by the electronics, which changes the sensor output state, indicating the presence of the material. When the probe element no longer makes contact with the target material, vibrations are generated again, and the output state returns to indicating the absence of the material.

Main features:

Applications:

The device is used for detecting the maximum and minimum levels of tanks or pipes filled with various solid/liquid materials. Examples of substances that can be monitored:

Industries where sensors can be used:

Technical Data:

| Dimensions [mm] |  |

|

|

|---|---|---|---|

| Model | SC1400 Standard | SC1410 with Extra Long Tuning Forks | SC1420 with Long Tuning Forks |

| Level Sensor Housing | Aluminum / IP65 | ||

| Sensor Material | SUS 304 / 316 / 316L | ||

| Mounting | 1”PT | ||

| Connector | ½”NPT x 2 | ||

| Maximum Vertical Rod Load | 20Nm | ||

| Process Pressure | 40 bar | ||

| Power Supply Voltage | 20…250V AC/DC 50/60Hz | ||

| Power Consumption | 10VA | ||

| Ambient Temperature | -40…60°C | ||

| Process Temperature | -40…130°C | ||

| Output Signal | Relay, SPDT, 5A/250V AC, 1 or 2 sets of SSR (MOSFET) 400mA/60V AC/DC, 1 or 2 sets | ||

| Minimum Detectable Material Density | Solid: ≥0.07g/cm³, Liquid: ≥0.7g/cm³ | ||

| Time Delay | 0.6s / Operation; 1-3s / Reset | ||

| Vibration Frequency | 350-370Hz | ||

| Selectable Sensitivity | High / Low | ||

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent