Category

Photos are for informational purposes only. View product specification

please use latin characters

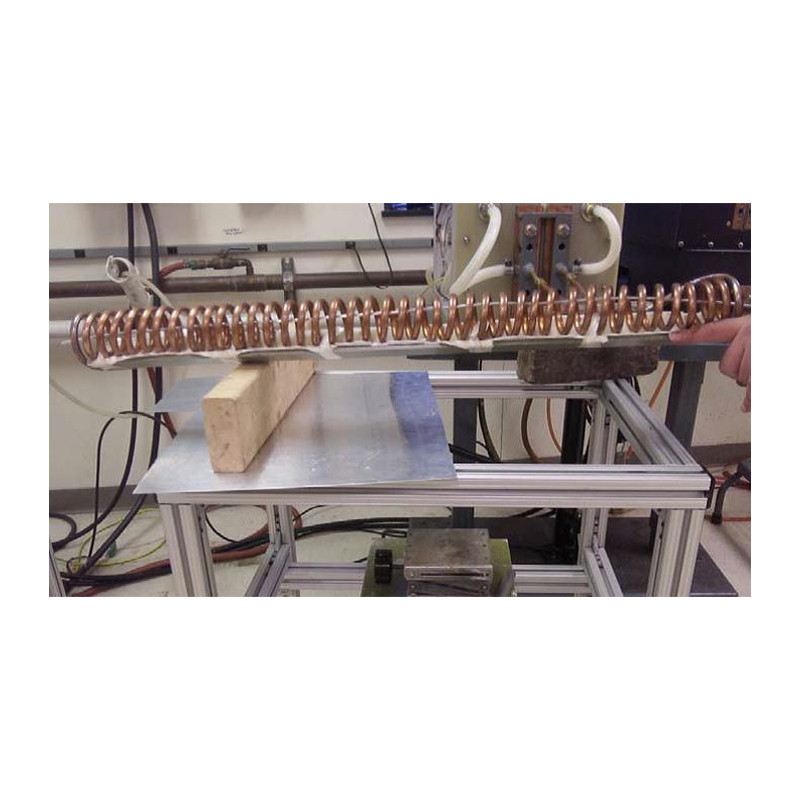

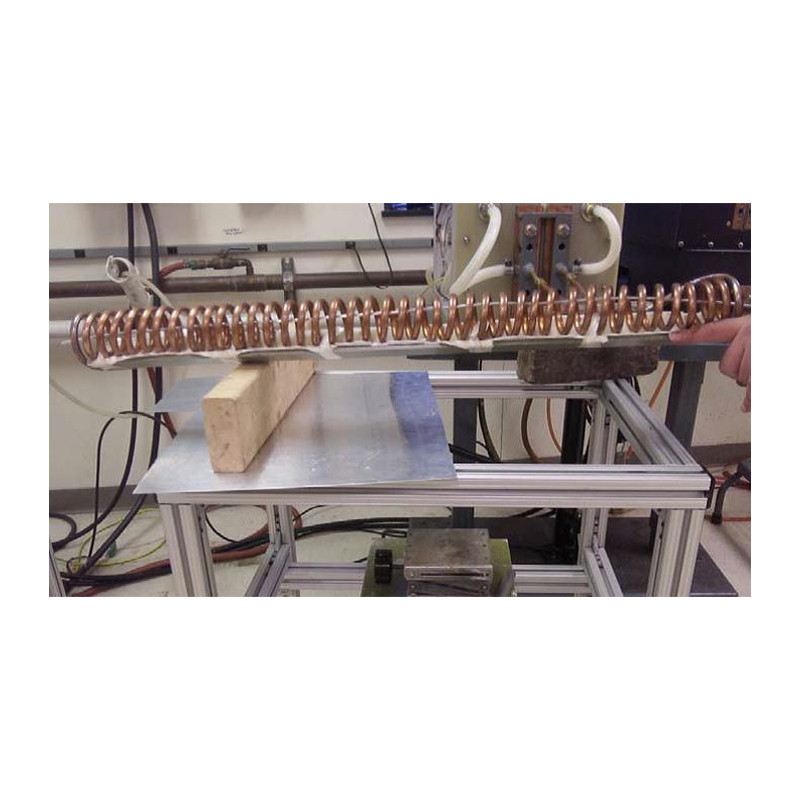

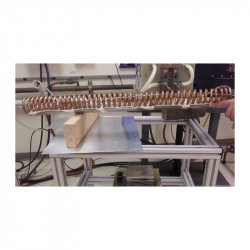

Objective: Heating the aluminum wire to achieve a temperature equal to that of the plastic coating applied to the wire

Material: Aluminum cable (diameter: 3.7 mm)

Temperature: 232 ºC

Frequency: 18 kHz

System: Ambrell EKOHEAT 50kW Induction heating system, 15-45 kHz with remote head, inductor consisting of 40 coils (length 0.8 m)

Process: It took 3 seconds to heat the wire to 232 ºC.

Results:

Are you interested in this product? Do you need additional information or individual pricing?

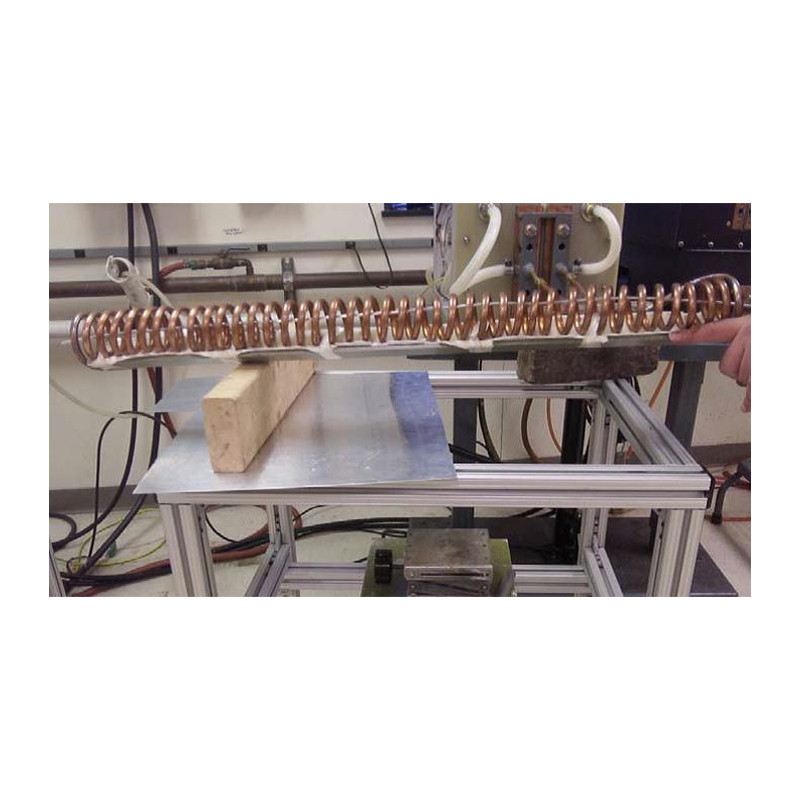

Objective: Heating the aluminum wire to achieve a temperature equal to that of the plastic coating applied to the wire

Material: Aluminum cable (diameter: 3.7 mm)

Temperature: 232 ºC

Frequency: 18 kHz

System: Ambrell EKOHEAT 50kW Induction heating system, 15-45 kHz with remote head, inductor consisting of 40 coils (length 0.8 m)

Process: It took 3 seconds to heat the wire to 232 ºC.

Results:

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent