Category

Photos are for informational purposes only. View product specification

please use latin characters

-1 : T - thernomid NV,

-2 : F - modified epoxide resin ,

-3 and 4: divided by 100 indicates non pressed final product thickness

-5 and 6: multiplied by 10 indicates weight for m2 of final product.

Characteristic:

Insulation material SEG type PF has better properties than normal insulation materials compatible with insulation class 155°C.

Polymerisation:

Temperature and polymerisation time can be adjusted to final product or resources: 3 min @190°C, 20 min @ 170°C, 45 min @150°C.

Storage:

SEGPREG's must be stored in cold room, far away from light and other heat sources, in temperature not higher than 25°C: 8 months with 5°C, 4 months with 23°C ± 2°C.

| Type | Film thickness[mm] | Surface weight | Thickness non pressed | Flow | volatile parts weight [mm] |

Break down voltage [kV] |

|||

|---|---|---|---|---|---|---|---|---|---|

| film [g/m2] |

overall [g/m2] |

resin [g/m2] |

resin [%] |

||||||

| Tolerance | ±10% | ±10% | ±12% | ±10% | ±5% | ±15% | min. | ||

| TF 1718 | 0,15 | 142 | 180 | 35 | 19 | 0,17 | < 0,8 | < 1 | 8,3 |

| TF 2121 | 0,18 | 177 | 215 | 38 | 19 | 0,21 | < 0,8 | < 1 | 9 |

| TF 2425 | 0,2 | 212 | 255 | 45 | 20 | 0,24 | < 0,8 | < 1 | 9,6 |

| TF 2729 | 0,24 | 247 | 290 | 43 | 18 | 0,27 | < 0,8 | < 1 | 10,5 |

| TF 3338 | 0,3 | 338 | 385 | 45 | 14 | 0,33 | < 0,8 | < 1 | 11,6 |

Marking:

Different SEGPREG's have markings containing a letter and digit combination:

-1: T - THERNOMID NV,

-2: F - modified epoxide resin

-3 and 4: multiplied by 10 indicates non pressed final product thickness,

-5 and 6: multiplied by 10 indicates weight for m2 of final product.

Characteristic:

It is well adjusted for insulation systems class 155°C.

Polymerisation:

Our recommendation: 3 min @ 190°C, 20 min @ 170°C, 45 min @ 150°C.

Storage:

SEGPREG's must be stored in cold room, far away from light and other heat sources, in temperature not higher than 25°C: 8 months with 5°C, 4 months with 23°C ± 2°C.

| Unit | Tolerance | TFr2729 | TFr3338 | TFr3846 | TFr4860 | |

|---|---|---|---|---|---|---|

| Film thickness | mm | ±15% | 0,24 | 0,3 | 0,35 | 0,45 |

| Film surface weight | g/m2 | ±12% | 247 | 338 | 422 | 562 |

| Overall surface weight | g/m2 | ±12% | 290 | 385 | 465 | 600 |

| Resin surface weight | g/m2 | ±10% | 43 | 45 | 45 | 45 |

| Resin layer | % | ±5 | 18 | 14 | 12 | 9 |

| non pressed thickness | mm | ±15% | 0,27 | 0,33 | 0,38 | 0,48 |

| Flow | % | < 0,8 | < 0,8 | < 0,8 | < 0,8 | |

| violate parts | % | < 1 | < 1 | < 1 | < 1 | |

| break down voltage | kV | min. | 10,6 | 11,6 | 14,6 | 18,6 |

Characteristic:

It is adjusted to insulation systems class F 155 °C.

Delivers:

Material can be delivered in rollers, sheets or groove insulation - for request.

Standard roller size: 1000mm.

Standard lengths on roller (thickness ± 0,5%):

0,05mm - 750m, 0,10mm - 380m, 0,15mm - 250m, 0,18mm - 210m, 0,24mm - 160m, 0,30mm - 120m, 0,40mm - 90m.

| Thickness | Tolerance | 2.05 | 2.2 | 2.4 | 2.5 | 2.75 | 2.1 | 2.14 | |

|---|---|---|---|---|---|---|---|---|---|

| Thickness | mm | 0,05 | 0,1 | 0,15 | 0,18 | 0,24 | 0,3 | 0,4 | |

| Tolerance | ± % | 15 | 15 | 15 | 15 | 15 | 10 | 10 | |

| Film thickness | mm | ±10% | 12 | 50 | 100 | 125 | 190 | 250 | 350 |

| Weight | g/m2 | ±12% | 46 | 116 | 186 | 221 | 312 | 396 | 536 |

| Efficiency | m2/kg | ±12% | 21,7 | 8,6 | 5,4 | 4,5 | 3,2 | 2,5 | 1,9 |

| Lengthening resistance MD | N/cm | min. | 35 | 100 | 145 | 180 | 270 | 315 | 360 |

| lengthening MD | % | min. | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Stretching resistance TD | N/cm | min. | 30 | 80 | 110 | 135 | 180 | 170 | 315 |

| Stretch TD | % | min. | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| Break down voltage | kV | min. | 2,5 | 4 | 6,5 | 7,5 | 12 | 15 | 19,5 |

| Characteristic: | |

| -melting point: | 255°C do 265°C, |

| -soften point: | 245°C, |

| -thermal constant resistance: | 155°C, |

| -thermal temporary resistance: | 195°C, |

| -thermal withstand: | -180°C in liquid nitrogen, |

| -shrink: | 2% @. 160°C during 30 min, |

| -line expansion coefficient | 3 x 10-5/°C, |

| -thermal conductance: | 0,085 W/m°C, |

| -specific heat: | 0,3 cal/g°C, |

| -water absorption: | < 0,6% in water @25°C during 24h, |

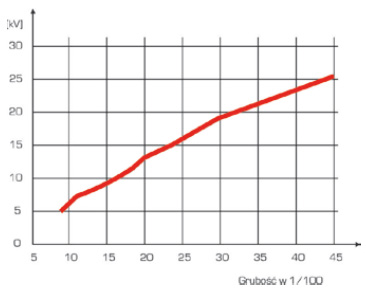

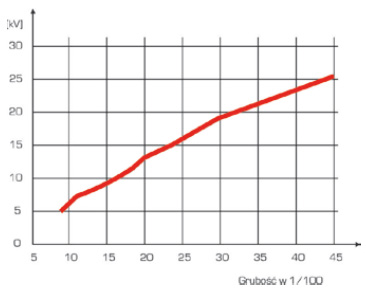

| -break down voltage: | see diagram |

| -resistance for stretching | 180daN/cm2, |

| -stretch: | 120%, |

| -Dielectric losses coefficient @ 50 Hz (tδ)in temp. 20°C: | 0, 005, |

| -dielectric constant 50 Hz (er) @ 20°C: | 2, 45 |

THERNOMID20.04 VF is produced in 9 thicknesses

| Thickness [mm] |

Tolerance | Polyester film thickness [µ] |

substance [g/m2] |

standard rollers |

|---|---|---|---|---|

| 0,09 | ± 10% | 23 | 75 ± 10% | 400 mb x 1000 mm |

| 0,11 | ± 10% | 36 | 90 ± 10% | 350 mb x 1000 mm |

| 0,15 | ± 5% | 50 | 150 ± 10% | 250 mb x 1000 mm |

| 0,18 | ± 5% | 75 | 185 ± 10% | 220 mb x 1000 mm |

| 0,20 | ± 5% | 100 | 220 ± 1 10% | 200 mb x 1000 mm |

| 0,30 | ± 5% | 125 | 255 ± 10% | 160 mb x 1000 mm |

| 0,30 | ± 5% | 190 | 345 ± 10% | 140 mb x 1000 mm |

| 0,35 | ± 5% | 250 | 430 ± 10% | 110 mb x 1000 mm |

| 0,45 | ± 5% | 350 | 570 ± 10% | 100 mb x 1000 mm |

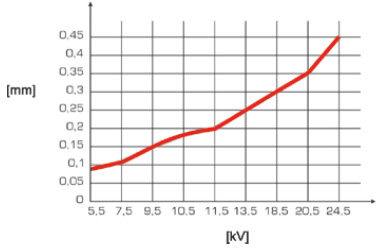

Insulation material for system class F 155°C.

| Characteristic: | |

| -Dielectric withstand: | 50 kV / mm, |

| dielectric constant 50 Hz @ 25°C: | 2,46 przy 20°C, |

| -dielectric losses coefficient @ 50 Hz 25°C: | 0,005 przy 20°C, |

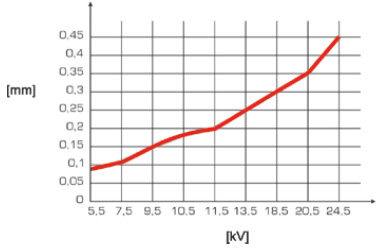

| -break down voltage: | patrz wykres, |

| -melting point: | > 250°C, |

| -soften point: | > 245°C, |

| -thermal constant resistance: | 155°C, |

| -thermal temporary resistance | 190°C, |

| -thermal minimal withstand: | - 180°C in liquid nitrogen, |

| -specific heat: | 0,3 kal/g °C, |

| -thermal conductance: | 0,085W/min°C, |

| -line stretch coefficient (30°C - 50°C): | 3x10-5/°C, |

| -resistance for stretching | 180 daN/cm2, |

| -stretch: | 120%, |

| -shrink: | 160°C @ 30min w 2%, |

| -absorption: | < 0,6%. |

THERNOMID NV is produced in 10 thicknesses

| Thickness [mm] |

Tolerance | Polyester film thickness [µ] |

substance [g/m2] |

Standard rollers |

|---|---|---|---|---|

| 0,09 | ± 10% | 23 | 69 ± 5% | 400 mb x 1000 mm |

| 0,10 | ± 10% | 36 | 87 ± 5% | 350 mb x 1000 mm |

| 0,15 | ± 10% | 50 | 142 ± 5% | 250 mb x 1000 mm |

| 0,18 | ± 10% | 75 | 177 ± 5% | 220 mb x 1000 mm |

| 0,20 | ± 10% | 100 | 212 ± 5% | 200 mb x 1000 mm |

| 0,23 | ± 10% | 75 | 215 ± 5% | 160 mb x 1000 mm |

| 0,24 | ± 10% | 125 | 247 ± 5% | 160 mb x 1000 mm |

| 0,30 | ± 10% | 190 | 338 ± 5% | 140 mb x 1000 mm |

| 0,35 | ± 10% | 250 | 422 ± 5% | 110 mb x 1000 mm |

| 0,45 | ± 10% | 350 | 562 ± 5% | 100 mb x 1000 mm |

| Characteristic: | |

| -melting point: | 255°C do 265°C, |

| -soften point: | 245°C, |

| -thermal constant resistance: | 155°C, |

| -thermal temporary resistance: | 180°C, |

| -shrink: | 2% @temp. 160°C during 30 min, |

| -line expansion coefficient: | 3x10-6/°C, |

| -break down voltage: | 12 kV |

| -resistance for stretching: | 120 daN/cm2, |

| -stretch: | 120%. |

THERNOPHASE is produced in 5 thicknesses

|

Thickness |

Tolerance | Polyester film thickness [µ] |

substance [g/m2] |

Standard rollers |

|---|---|---|---|---|

| 0,33 | ± 5% | 50 | 150 ± 5% | 200 mb x 1000 mm |

| 0,36 | ± 5% | 75 | 185 ± 5% | 160 mb x 1000 mm |

| 0,38 | ± 5% | 100 | 220 ± 5% | 140 mb x 1000 mm |

| 0.40 | ± 5% | 125 | 255 ± 5% | 120 mb x 1000 mm |

| 0,47 | ± 5% | 190 | 340 ± 5% | 100 mb x 1000 mm |

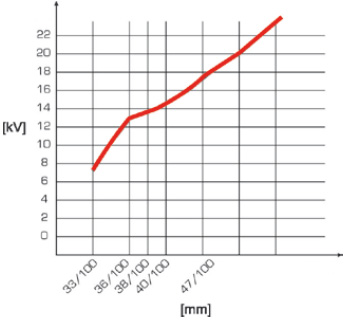

| Characteristic: | |

| - melting point: | 255°C do 265°C, |

| - soften point: | 245°C, |

| - thermal constant resistance: | 155°C, |

| - thermal temporary resistance: | 190°C, |

| - thermal min withstand: | -180°C in liquid nitrogen, |

| - shrink: | 2% w temp. 160°C during 30 min., |

| - line expansion coefficient: | 3x10-5/°C, |

| - specific heat: | 0,3 cal /g°C, |

| - absorption:: | < 0,6% in water o temp. 25°C during24h, |

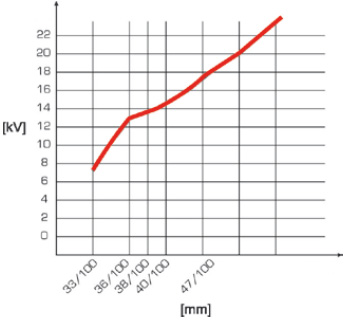

| - break down voltage: | see chart on 1144 page, |

| Thickness [mm] |

Tolerance | Aramid paper thickness [mm] |

Polyester film thickness [µ] |

substance [g/m2] |

Standard rollers |

|---|---|---|---|---|---|

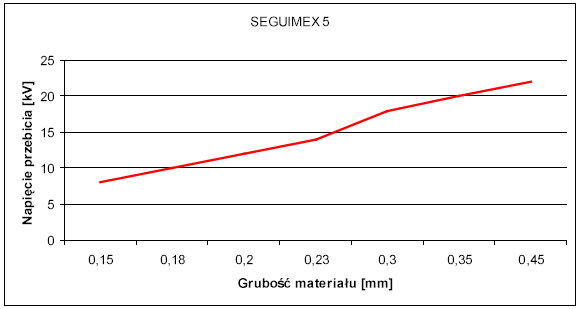

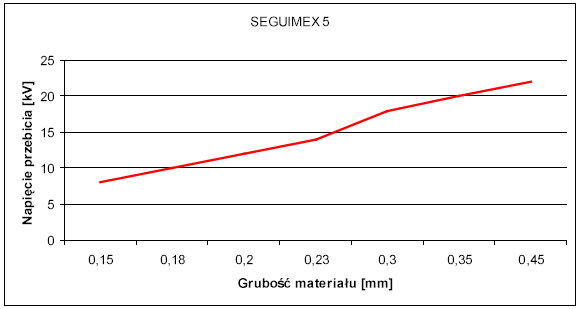

| SEGUIMEX 5 | |||||

| 0,15 | ± 10% | 0,05 | 36 | 140 ± 5% | 250 mb x 914 mm |

| 0,20 | ± 10% | 0,05 | 100 | 230 ± 5% | 200 mb x 914 mm |

| 0,25 | ± 10% | 0,05 | 125 | 265 ± 5% | 160 mb x 914 mm |

| 0,30 | ± 10% | 0,05 | 190 | 355 ± 5% | 140 mb x 914 mm |

| 0,35 | ± 10% | 0,05 | 250 | 440 ± 5% | 110 mb x 914 mm |

| 0,45 | ± 10% | 0,05 | 350 | 580 ± 5% | 100 mb x 914 mm |

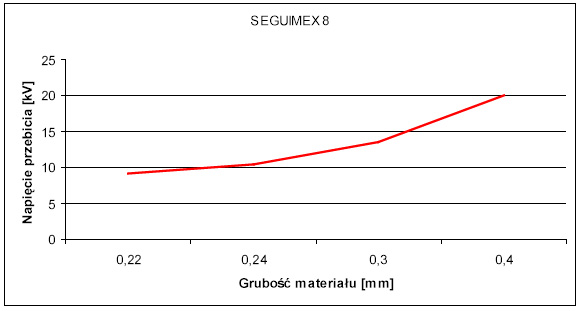

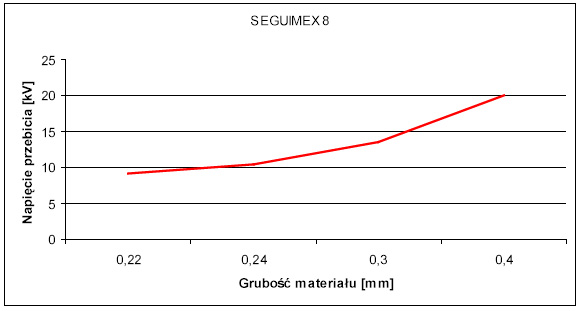

| SEGUIMEX 8 | |||||

| 0,22 | ± 10% | 0,08 | 50 | 210 ± 5% | 180 mb x 914 mm |

| 0,25 | ± 10% | 0,08 | 75 | 245 ± 5% | 150 mb x 914 mm |

| 0,32 | ± 10% | 0,08 | 125 | 315 ± 5% | 120 mb x 914 mm |

| 0,40 | ± 10% | 0,08 | 250 | 405 ± 5% | 100 mb x 914 mm |

| Thickness [mm] |

Tolerance | Aramid paper thickness [mm] |

Thickness błonki poliestrowej [µ] |

substance [g/m2] |

Standard rollers |

|---|---|---|---|---|---|

| SEGUIMEX 5 | |||||

| 0,23 | ± 10% | 0,05 | 175 | 294 ± 5% | 160 mb x 914 mm |

| 0,30 | ± 10% | 0,05 | 250 | 399 ± 5% | 120 mb x 914 mm |

| SEGUIMEX 8 | |||||

| 0,19 | ± 10% | 0,08 | 100 | 213 ± 5% | 200 mb x 914 mm |

| 0,26 | ± 10% | 0,08 | 175 | 319 ± 5% | 160 mb x 914 mm |

| 0,33 | ± 10% | 0,08 | 250 | 424 ± 5% | 120 mb x 914 mm |

| 0,43 | ± 10% | 0,08 | 350 | 563 ± 5% | 100 mb x 914 mm |

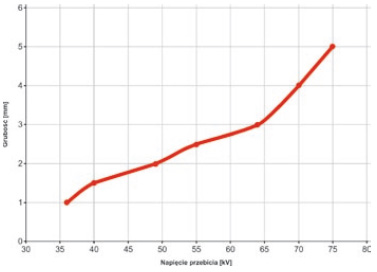

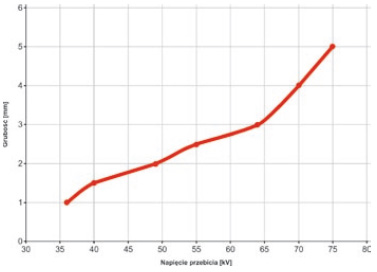

THERNOSTRAT20.04 VF

| Characteristic: | ||

| -dielectric withstand: | NFC 26225 | 52 kV/mm, |

| -break down voltage: | NFC26230 | patrz krzywa kV, |

| -melting point: | Fischer-Jones | >250 °C, |

| -soften point: | ASTM D 876-65 | >245 °C, |

| -constant operation temperature: | NFC26205 | 155 °C, |

| -max temporary temperature: | NFC26205 | 190°C, |

| -min operating temperature: | NFC26205 | -180 °C w ciekłym azocie, |

| -specific heat: | NF PRG 62011 i ASTM C 518 | 0,3 cal/g °C, |

| -line expansion coefficient(z 30 do 50°C): | ASTM D 696-44 | 0,00003 mm/°C, |

| -shrink @ 160°C during 30 min: | < 1,5%, | |

| -zdolność do wchłaniania wody: | NSEG 0017 | < 0,6 %. |

THERNOSTRAT 20.04 VF is produced in 8 thicknesses

| Thickness - Tolerance | Weight [g/m2] |

Standard size |

|---|---|---|

| 1,0 ± 10% | 1174 ± 10% | 980 mm x 980 mm |

| 1,5 ± 10% | 1766 ± 10% | 980 mm x 980 mm |

| 2,0 ± 10% | 2350 ± 10% | 980 mm x 980 mm |

| 2,5 ± 10% | 3050 ± 10% | 980 mm x 980 mm |

| 3,0 ± 10% | 3672 ± 10% | 980 mm x 980 mm |

| 4,0 ± 10% | 4895 ± 10% | 980 mm x 980 mm |

| 4,5 ± 10% | 5870 ± 10% | 980 mm x 980 mm |

| 5,0 ± 10% | 6457 ± 10% | 980 mm x 980 mm |

Are you interested in this product? Do you need additional information or individual pricing?

-1 : T - thernomid NV,

-2 : F - modified epoxide resin ,

-3 and 4: divided by 100 indicates non pressed final product thickness

-5 and 6: multiplied by 10 indicates weight for m2 of final product.

Characteristic:

Insulation material SEG type PF has better properties than normal insulation materials compatible with insulation class 155°C.

Polymerisation:

Temperature and polymerisation time can be adjusted to final product or resources: 3 min @190°C, 20 min @ 170°C, 45 min @150°C.

Storage:

SEGPREG's must be stored in cold room, far away from light and other heat sources, in temperature not higher than 25°C: 8 months with 5°C, 4 months with 23°C ± 2°C.

| Type | Film thickness[mm] | Surface weight | Thickness non pressed | Flow | volatile parts weight [mm] |

Break down voltage [kV] |

|||

|---|---|---|---|---|---|---|---|---|---|

| film [g/m2] |

overall [g/m2] |

resin [g/m2] |

resin [%] |

||||||

| Tolerance | ±10% | ±10% | ±12% | ±10% | ±5% | ±15% | min. | ||

| TF 1718 | 0,15 | 142 | 180 | 35 | 19 | 0,17 | < 0,8 | < 1 | 8,3 |

| TF 2121 | 0,18 | 177 | 215 | 38 | 19 | 0,21 | < 0,8 | < 1 | 9 |

| TF 2425 | 0,2 | 212 | 255 | 45 | 20 | 0,24 | < 0,8 | < 1 | 9,6 |

| TF 2729 | 0,24 | 247 | 290 | 43 | 18 | 0,27 | < 0,8 | < 1 | 10,5 |

| TF 3338 | 0,3 | 338 | 385 | 45 | 14 | 0,33 | < 0,8 | < 1 | 11,6 |

Marking:

Different SEGPREG's have markings containing a letter and digit combination:

-1: T - THERNOMID NV,

-2: F - modified epoxide resin

-3 and 4: multiplied by 10 indicates non pressed final product thickness,

-5 and 6: multiplied by 10 indicates weight for m2 of final product.

Characteristic:

It is well adjusted for insulation systems class 155°C.

Polymerisation:

Our recommendation: 3 min @ 190°C, 20 min @ 170°C, 45 min @ 150°C.

Storage:

SEGPREG's must be stored in cold room, far away from light and other heat sources, in temperature not higher than 25°C: 8 months with 5°C, 4 months with 23°C ± 2°C.

| Unit | Tolerance | TFr2729 | TFr3338 | TFr3846 | TFr4860 | |

|---|---|---|---|---|---|---|

| Film thickness | mm | ±15% | 0,24 | 0,3 | 0,35 | 0,45 |

| Film surface weight | g/m2 | ±12% | 247 | 338 | 422 | 562 |

| Overall surface weight | g/m2 | ±12% | 290 | 385 | 465 | 600 |

| Resin surface weight | g/m2 | ±10% | 43 | 45 | 45 | 45 |

| Resin layer | % | ±5 | 18 | 14 | 12 | 9 |

| non pressed thickness | mm | ±15% | 0,27 | 0,33 | 0,38 | 0,48 |

| Flow | % | < 0,8 | < 0,8 | < 0,8 | < 0,8 | |

| violate parts | % | < 1 | < 1 | < 1 | < 1 | |

| break down voltage | kV | min. | 10,6 | 11,6 | 14,6 | 18,6 |

Characteristic:

It is adjusted to insulation systems class F 155 °C.

Delivers:

Material can be delivered in rollers, sheets or groove insulation - for request.

Standard roller size: 1000mm.

Standard lengths on roller (thickness ± 0,5%):

0,05mm - 750m, 0,10mm - 380m, 0,15mm - 250m, 0,18mm - 210m, 0,24mm - 160m, 0,30mm - 120m, 0,40mm - 90m.

| Thickness | Tolerance | 2.05 | 2.2 | 2.4 | 2.5 | 2.75 | 2.1 | 2.14 | |

|---|---|---|---|---|---|---|---|---|---|

| Thickness | mm | 0,05 | 0,1 | 0,15 | 0,18 | 0,24 | 0,3 | 0,4 | |

| Tolerance | ± % | 15 | 15 | 15 | 15 | 15 | 10 | 10 | |

| Film thickness | mm | ±10% | 12 | 50 | 100 | 125 | 190 | 250 | 350 |

| Weight | g/m2 | ±12% | 46 | 116 | 186 | 221 | 312 | 396 | 536 |

| Efficiency | m2/kg | ±12% | 21,7 | 8,6 | 5,4 | 4,5 | 3,2 | 2,5 | 1,9 |

| Lengthening resistance MD | N/cm | min. | 35 | 100 | 145 | 180 | 270 | 315 | 360 |

| lengthening MD | % | min. | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Stretching resistance TD | N/cm | min. | 30 | 80 | 110 | 135 | 180 | 170 | 315 |

| Stretch TD | % | min. | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| Break down voltage | kV | min. | 2,5 | 4 | 6,5 | 7,5 | 12 | 15 | 19,5 |

| Characteristic: | |

| -melting point: | 255°C do 265°C, |

| -soften point: | 245°C, |

| -thermal constant resistance: | 155°C, |

| -thermal temporary resistance: | 195°C, |

| -thermal withstand: | -180°C in liquid nitrogen, |

| -shrink: | 2% @. 160°C during 30 min, |

| -line expansion coefficient | 3 x 10-5/°C, |

| -thermal conductance: | 0,085 W/m°C, |

| -specific heat: | 0,3 cal/g°C, |

| -water absorption: | < 0,6% in water @25°C during 24h, |

| -break down voltage: | see diagram |

| -resistance for stretching | 180daN/cm2, |

| -stretch: | 120%, |

| -Dielectric losses coefficient @ 50 Hz (tδ)in temp. 20°C: | 0, 005, |

| -dielectric constant 50 Hz (er) @ 20°C: | 2, 45 |

THERNOMID20.04 VF is produced in 9 thicknesses

| Thickness [mm] |

Tolerance | Polyester film thickness [µ] |

substance [g/m2] |

standard rollers |

|---|---|---|---|---|

| 0,09 | ± 10% | 23 | 75 ± 10% | 400 mb x 1000 mm |

| 0,11 | ± 10% | 36 | 90 ± 10% | 350 mb x 1000 mm |

| 0,15 | ± 5% | 50 | 150 ± 10% | 250 mb x 1000 mm |

| 0,18 | ± 5% | 75 | 185 ± 10% | 220 mb x 1000 mm |

| 0,20 | ± 5% | 100 | 220 ± 1 10% | 200 mb x 1000 mm |

| 0,30 | ± 5% | 125 | 255 ± 10% | 160 mb x 1000 mm |

| 0,30 | ± 5% | 190 | 345 ± 10% | 140 mb x 1000 mm |

| 0,35 | ± 5% | 250 | 430 ± 10% | 110 mb x 1000 mm |

| 0,45 | ± 5% | 350 | 570 ± 10% | 100 mb x 1000 mm |

Insulation material for system class F 155°C.

| Characteristic: | |

| -Dielectric withstand: | 50 kV / mm, |

| dielectric constant 50 Hz @ 25°C: | 2,46 przy 20°C, |

| -dielectric losses coefficient @ 50 Hz 25°C: | 0,005 przy 20°C, |

| -break down voltage: | patrz wykres, |

| -melting point: | > 250°C, |

| -soften point: | > 245°C, |

| -thermal constant resistance: | 155°C, |

| -thermal temporary resistance | 190°C, |

| -thermal minimal withstand: | - 180°C in liquid nitrogen, |

| -specific heat: | 0,3 kal/g °C, |

| -thermal conductance: | 0,085W/min°C, |

| -line stretch coefficient (30°C - 50°C): | 3x10-5/°C, |

| -resistance for stretching | 180 daN/cm2, |

| -stretch: | 120%, |

| -shrink: | 160°C @ 30min w 2%, |

| -absorption: | < 0,6%. |

THERNOMID NV is produced in 10 thicknesses

| Thickness [mm] |

Tolerance | Polyester film thickness [µ] |

substance [g/m2] |

Standard rollers |

|---|---|---|---|---|

| 0,09 | ± 10% | 23 | 69 ± 5% | 400 mb x 1000 mm |

| 0,10 | ± 10% | 36 | 87 ± 5% | 350 mb x 1000 mm |

| 0,15 | ± 10% | 50 | 142 ± 5% | 250 mb x 1000 mm |

| 0,18 | ± 10% | 75 | 177 ± 5% | 220 mb x 1000 mm |

| 0,20 | ± 10% | 100 | 212 ± 5% | 200 mb x 1000 mm |

| 0,23 | ± 10% | 75 | 215 ± 5% | 160 mb x 1000 mm |

| 0,24 | ± 10% | 125 | 247 ± 5% | 160 mb x 1000 mm |

| 0,30 | ± 10% | 190 | 338 ± 5% | 140 mb x 1000 mm |

| 0,35 | ± 10% | 250 | 422 ± 5% | 110 mb x 1000 mm |

| 0,45 | ± 10% | 350 | 562 ± 5% | 100 mb x 1000 mm |

| Characteristic: | |

| -melting point: | 255°C do 265°C, |

| -soften point: | 245°C, |

| -thermal constant resistance: | 155°C, |

| -thermal temporary resistance: | 180°C, |

| -shrink: | 2% @temp. 160°C during 30 min, |

| -line expansion coefficient: | 3x10-6/°C, |

| -break down voltage: | 12 kV |

| -resistance for stretching: | 120 daN/cm2, |

| -stretch: | 120%. |

THERNOPHASE is produced in 5 thicknesses

|

Thickness |

Tolerance | Polyester film thickness [µ] |

substance [g/m2] |

Standard rollers |

|---|---|---|---|---|

| 0,33 | ± 5% | 50 | 150 ± 5% | 200 mb x 1000 mm |

| 0,36 | ± 5% | 75 | 185 ± 5% | 160 mb x 1000 mm |

| 0,38 | ± 5% | 100 | 220 ± 5% | 140 mb x 1000 mm |

| 0.40 | ± 5% | 125 | 255 ± 5% | 120 mb x 1000 mm |

| 0,47 | ± 5% | 190 | 340 ± 5% | 100 mb x 1000 mm |

| Characteristic: | |

| - melting point: | 255°C do 265°C, |

| - soften point: | 245°C, |

| - thermal constant resistance: | 155°C, |

| - thermal temporary resistance: | 190°C, |

| - thermal min withstand: | -180°C in liquid nitrogen, |

| - shrink: | 2% w temp. 160°C during 30 min., |

| - line expansion coefficient: | 3x10-5/°C, |

| - specific heat: | 0,3 cal /g°C, |

| - absorption:: | < 0,6% in water o temp. 25°C during24h, |

| - break down voltage: | see chart on 1144 page, |

| Thickness [mm] |

Tolerance | Aramid paper thickness [mm] |

Polyester film thickness [µ] |

substance [g/m2] |

Standard rollers |

|---|---|---|---|---|---|

| SEGUIMEX 5 | |||||

| 0,15 | ± 10% | 0,05 | 36 | 140 ± 5% | 250 mb x 914 mm |

| 0,20 | ± 10% | 0,05 | 100 | 230 ± 5% | 200 mb x 914 mm |

| 0,25 | ± 10% | 0,05 | 125 | 265 ± 5% | 160 mb x 914 mm |

| 0,30 | ± 10% | 0,05 | 190 | 355 ± 5% | 140 mb x 914 mm |

| 0,35 | ± 10% | 0,05 | 250 | 440 ± 5% | 110 mb x 914 mm |

| 0,45 | ± 10% | 0,05 | 350 | 580 ± 5% | 100 mb x 914 mm |

| SEGUIMEX 8 | |||||

| 0,22 | ± 10% | 0,08 | 50 | 210 ± 5% | 180 mb x 914 mm |

| 0,25 | ± 10% | 0,08 | 75 | 245 ± 5% | 150 mb x 914 mm |

| 0,32 | ± 10% | 0,08 | 125 | 315 ± 5% | 120 mb x 914 mm |

| 0,40 | ± 10% | 0,08 | 250 | 405 ± 5% | 100 mb x 914 mm |

| Thickness [mm] |

Tolerance | Aramid paper thickness [mm] |

Thickness błonki poliestrowej [µ] |

substance [g/m2] |

Standard rollers |

|---|---|---|---|---|---|

| SEGUIMEX 5 | |||||

| 0,23 | ± 10% | 0,05 | 175 | 294 ± 5% | 160 mb x 914 mm |

| 0,30 | ± 10% | 0,05 | 250 | 399 ± 5% | 120 mb x 914 mm |

| SEGUIMEX 8 | |||||

| 0,19 | ± 10% | 0,08 | 100 | 213 ± 5% | 200 mb x 914 mm |

| 0,26 | ± 10% | 0,08 | 175 | 319 ± 5% | 160 mb x 914 mm |

| 0,33 | ± 10% | 0,08 | 250 | 424 ± 5% | 120 mb x 914 mm |

| 0,43 | ± 10% | 0,08 | 350 | 563 ± 5% | 100 mb x 914 mm |

THERNOSTRAT20.04 VF

| Characteristic: | ||

| -dielectric withstand: | NFC 26225 | 52 kV/mm, |

| -break down voltage: | NFC26230 | patrz krzywa kV, |

| -melting point: | Fischer-Jones | >250 °C, |

| -soften point: | ASTM D 876-65 | >245 °C, |

| -constant operation temperature: | NFC26205 | 155 °C, |

| -max temporary temperature: | NFC26205 | 190°C, |

| -min operating temperature: | NFC26205 | -180 °C w ciekłym azocie, |

| -specific heat: | NF PRG 62011 i ASTM C 518 | 0,3 cal/g °C, |

| -line expansion coefficient(z 30 do 50°C): | ASTM D 696-44 | 0,00003 mm/°C, |

| -shrink @ 160°C during 30 min: | < 1,5%, | |

| -zdolność do wchłaniania wody: | NSEG 0017 | < 0,6 %. |

THERNOSTRAT 20.04 VF is produced in 8 thicknesses

| Thickness - Tolerance | Weight [g/m2] |

Standard size |

|---|---|---|

| 1,0 ± 10% | 1174 ± 10% | 980 mm x 980 mm |

| 1,5 ± 10% | 1766 ± 10% | 980 mm x 980 mm |

| 2,0 ± 10% | 2350 ± 10% | 980 mm x 980 mm |

| 2,5 ± 10% | 3050 ± 10% | 980 mm x 980 mm |

| 3,0 ± 10% | 3672 ± 10% | 980 mm x 980 mm |

| 4,0 ± 10% | 4895 ± 10% | 980 mm x 980 mm |

| 4,5 ± 10% | 5870 ± 10% | 980 mm x 980 mm |

| 5,0 ± 10% | 6457 ± 10% | 980 mm x 980 mm |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent