-

- Impregnation method

- Alkyd lacquer - modified, single component, WE203 for insulation F class system 155C

- Air dry lacquers - anti-flame - protective and for finish G141, G142, G144T, G145

- Alkyd lacquer - modified G159, G159T

- Epoxide-alkyd lacquer - modified - E521, E521T, E521ATX

- E524TS lacquer - H class - UL E104619(N) certificate

- Polyester nonimpregnated lacquer P721, polymerization in drier

-

- Epoxide resins - impregnation methods

- Polyurethane resins - impregnation methods

- Two component resin U4612 + D84-15 - polymerization in an environmental temperature

- Two component resin U4760 + D72- polymerization in an environmental temperature

- Two component resin U4720 + D71- polymerization in an environmental temperature

- Two component resin with insert DIAPOL 508 + C500,- polymerization in an room temperature

- Two component resin with insert DIAPOL 509FG + C500,- polymerization in an room temperature

- Two component resin without filler JBR19.4 + D19.4 - polymerization in an environmental temperature

- Two component resin with insert E519C + D69,- polymerization in an room temperature

- Two component resin with insert E520C + D88,- polymerization in an environmental temperature

- Two component resin with load E819CA + D91,- polymerization in an room temperature

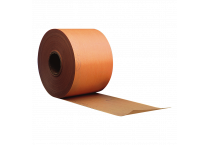

We offer a wide range of flexible insulating materials, which are manufactured in temperature classes from B 130°C to H 180°C. These materials have excellent dielectric properties and are supplied in rolls or sheets. It is also possible to cut them or supply pre-formed slot insulation. The main applications of flexible insulating materials are transformers and electric motors.

Insulating materials can also be supplied in the form of tapes. These electro-insulating tapes, used in the production of electrical and electronic components, must have the appropriate electrical and mechanical properties, as well as meet the required technological characteristics. Behind a simple roll of adhesive tape lies complex materials science, advanced technologies, and production processes.

Electro-insulating adhesive tapes are used for:

- insulation;

- protection;

- marking;

- fastening.

The insulating properties of tapes are determined by the type and thickness of the tape's base, insulation resistance, dielectric strength of the base, and tape's resistance to aging. An important factor in choosing insulating tape is the consideration of the possibility of electrolytic corrosion of the conductor due to its chemical interaction with the tape components in the presence of electrical potential, moisture, and other environmental factors. Electrolytic corrosion can lead to conductor breakage or breakdown of the enamel insulation of thin wires, for example, in a transformer coil winding. To reduce the likelihood of corrosion, the sulfur and chloride content in the material from which the tape is made should be minimized.

Many manufacturers use tapes for color coding of their products or as identification material. In this case, it is important that the tape does not fade, has good adhesive properties, and is suitable for marking. Finally, tapes are used to fasten components and wires. In this case, the most frequently considered parameters are: tear resistance, elongation, and adhesive properties.

Impregnating varnishes in DACPOL's offer

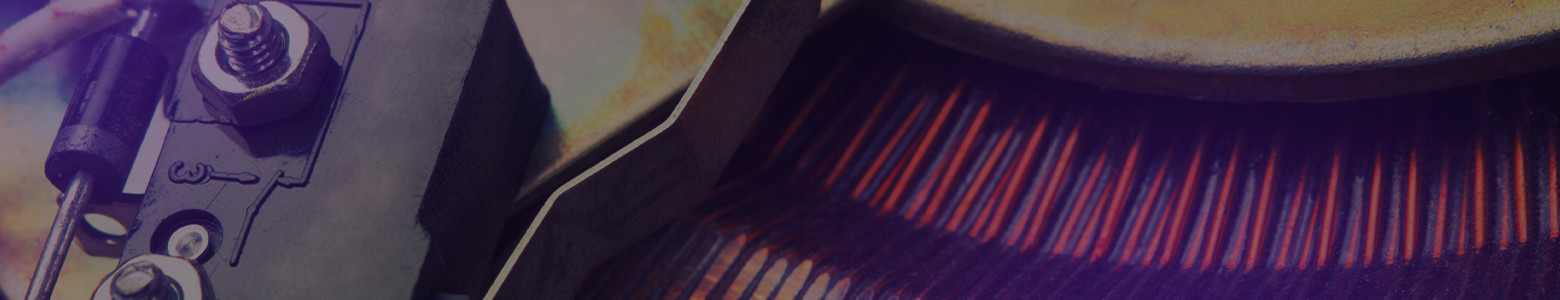

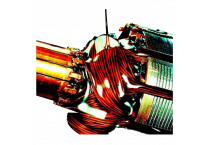

We also offer impregnating varnishes in classes B 130, F 155, and H 180°C. The main applications of varnishes are the impregnation of motor and transformer windings, performed by methods such as pouring, dipping, vacuum method, or drop method.

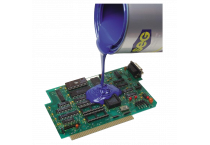

We also offer polyurethane and epoxy resins - two-component. The polymerization of the resins can take place at ambient temperature or in an oven at elevated temperature.

We offer a wide range of flexible insulating materials, which are manufactured in temperature classes from B 130°C to H 180°C. These materials have excellent dielectric properties and are supplied in rolls or sheets. It is also possible to cut them or supply pre-formed slot insulation. The main applications of flexible insulating materials are transformers and electric motors.

Insulating materials can also be supplied in the form of tapes. These electro-insulating tapes, used in the production of electrical and electronic components, must have the appropriate electrical and mechanical properties, as well as meet the required technological characteristics. Behind a simple roll of adhesive tape lies complex materials science, advanced technologies, and production processes.

Electro-insulating adhesive tapes are used for:

- insulation;

- protection;

- marking;

- fastening.

The insulating properties of tapes are determined by the type and thickness of the tape's base, insulation resistance, dielectric strength of the base, and tape's resistance to aging. An important factor in choosing insulating tape is the consideration of the possibility of electrolytic corrosion of the conductor due to its chemical interaction with the tape components in the presence of electrical potential, moisture, and other environmental factors. Electrolytic corrosion can lead to conductor breakage or breakdown of the enamel insulation of thin wires, for example, in a transformer coil winding. To reduce the likelihood of corrosion, the sulfur and chloride content in the material from which the tape is made should be minimized.

Many manufacturers use tapes for color coding of their products or as identification material. In this case, it is important that the tape does not fade, has good adhesive properties, and is suitable for marking. Finally, tapes are used to fasten components and wires. In this case, the most frequently considered parameters are: tear resistance, elongation, and adhesive properties.

Impregnating varnishes in DACPOL's offer

We also offer impregnating varnishes in classes B 130, F 155, and H 180°C. The main applications of varnishes are the impregnation of motor and transformer windings, performed by methods such as pouring, dipping, vacuum method, or drop method.

We also offer polyurethane and epoxy resins - two-component. The polymerization of the resins can take place at ambient temperature or in an oven at elevated temperature.

Coolant Vanchem products

Additionally, we also offer specialized cooling fluids COOLANT -10, COOLANT -45, and COOLANT -55. These products are formulated with ethylene glycol, deionized water, and special inhibitors, making them ideal as heat transfer media in liquid-cooled inverters, such as the PowerFlex 7000. The offered coolants Vanchem meet the latest standards, providing not only effective corrosion protection but also maintaining optimal thermal conductivity.