The article discusses how to choose the appropriate thread locking products, including anaerobic adhesives, spring washers, and tapes. The tips cover factors that influence the choice, as well as practical application advice.

Knowledge Base

-

What Are Anaerobic Adhesives?Read more

Learn about anaerobic adhesives, how they work, and the benefits they offer in challenging environments. Explore their applications in high-temperature, vibration, and pressure conditions, and discover how they contribute to the durability of threaded connections. Understand their diverse uses across industries like automotive, food production, and pharmaceuticals.

-

Vector Analysis of Circuits: The Key to Precise Electronics Design and DiagnosticsRead more

Vector analysis of circuits is an advanced method used in electronics to evaluate electrical circuits, particularly in the context of alternating current (AC) signals. By representing signals and impedances as vectors in the complex plane, it allows for precise visualization and analysis of their behavior as a function of frequency.

-

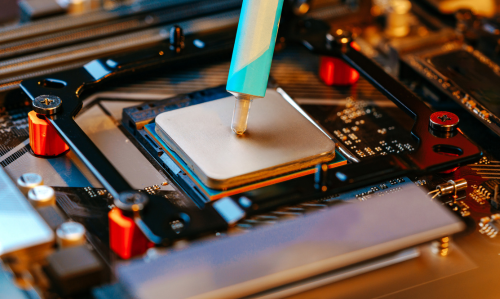

Application of Liquid Thermal Conductive Materials in the Electronics Industry: Effective Cooling for Performance and ReliabilityRead more

In today's world, where more and more electronic devices generate significant amounts of heat, efficient cooling becomes a key factor in ensuring the reliability and performance of these systems. In response to this challenge, the electronics industry is increasingly turning to innovative solutions such as liquid thermal conductive materials.

-

Comparison of capacitive and resistive touch panels: Which solution is better for your business?Read more

Choosing the right touch solution can be a challenge for many companies looking to implement innovative technologies in their products or processes. The two most commonly used types – capacitive touch screens and resistive touch panels – have unique advantages and are used in various environments. Understanding these differences will help select the ideal solution to ensure optimal performance, durability, and user convenience in a given application.

-

Environmental resistance of capacitive touch panels: Key features for industrial applicationsRead more

In industry, the reliability and durability of devices are crucial, especially in challenging environmental conditions. In many sectors, such as manufacturing, logistics, energy, or heavy industry, technologies must withstand various challenges – from extreme temperatures and high humidity to dust and chemical exposure. In this context, capacitive touch screens stand out due to advanced technology and appropriate design, enabling their use in demanding environments.

-

How to choose the right resistive touch panel for industrial applicationsRead more

In the industry, automation and digitization of processes are increasingly important, often involving the use of advanced user interfaces like touch panels. In many industrial applications, choosing the right touch panel is a challenge, especially when adapting to specific working conditions such as high humidity, dust, or the need for glove operation. Resistive touch panels are a popular choice in industrial applications due to their durability and reliability. In the article below, we will...

-

Resistive touch panels: why are they the ideal solution for industry?Read more

Touch technologies play a key role in process automation and management across various industrial sectors. Among the different types of touchscreens, resistive touch panels stand out as one of the most reliable solutions for harsh working conditions. Thanks to their durability and simplicity of operation, resistive screens have become an ideal choice for many industrial applications where durability and precision are priorities.

-

How to Safely Connect POWERSAFE (POWERLOCK) ConnectorsRead more

In this article, we will discuss how to correctly connect cables to the Powersafe Sequential Mating Box power distribution unit.

-

5 Best Methods for Installing POWERSAFE (POWERLOCK) ConnectorsRead more

In this article, we will examine the first two methods, discussing their key steps and recommendations.

-

STANEX transport casesRead more

STANEX transport cases are designed with the highest level of stability in mind and provide protection against all significant environmental threats.

-

Capacitive touch screens: How they work and their application in industryRead more

Capacitive touch screens play a crucial role in the modern world of technology, and their application in industry is becoming increasingly common. Thanks to their reliability and precision, capacitive touch panels are used in many industrial sectors, from automation to medical devices. But how exactly does a capacitive touchscreen work, and why is it so popular in industry? Let’s take a look at its operating principles and key advantages.

-

What are conductive elastomers and how can they improve electromagnetic compatibility?Read more

Electromagnetic compatibility (EMC) is a crucial aspect in the design of modern electronic devices. Conductive elastomers play an important role in improving EMC, offering effective solutions for controlling electromagnetic interference.

-

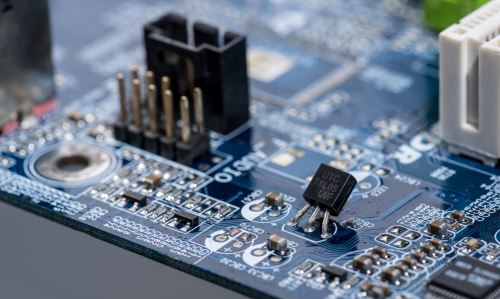

Best Practices for Shielding Components on PCBs for EMC: How to Minimize Electromagnetic InterferenceRead more

With the growing demands for electromagnetic compatibility (EMC), designing printed circuit boards (PCBs) is becoming increasingly complex. Shielding is a key technique that protects electronic components from electromagnetic interference (EMI). In this article, we discuss the main challenges and best practices related to designing shielding for PCB components in terms of EMC.

-

Precision and Versatility: Why Invest in the IVT-3?Read more

The IVT-3 current sensor, available in Base and PRO versions, offers precise measurement of current, temperature, and advanced diagnostic functions. The PRO version additionally enables voltage measurement and insulation status evaluation, making it a versatile tool ideal for modern electrical applications, ensuring high accuracy and integration of multiple functions.

-

What Are the Types of EMC Filters and When Are They Used?Read more

EMC filters play a key role in ensuring the electromagnetic compatibility of electrical and electronic systems. Their task is to minimize electromagnetic interference that can affect the operation of devices and systems. In this article, we will discuss different types of EMC filters and the situations in which they are most commonly used.

-

Selecting the Right EMC Cable GlandsRead more

Selecting the right EMC cable glands is crucial for effective protection against electromagnetic interference. Factors to consider include the material from which the gland is made, its size, and the type of cable it will be used with. The material of the gland significantly impacts its effectiveness in providing EMC protection. Metal glands offer better protection against interference than those made of plastic.

-

Overview of EMC Technologies Used in Automation SystemsRead more

Electromagnetic Compatibility (EMC) is a key aspect in the design and operation of modern automation systems. Its importance is invaluable in ensuring the reliability and stability of complex electronic devices, which must operate without electromagnetic interference both internally and with their surroundings.