-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

-

Cables for extreme applications

- Extension and Compensation cables

- Thermocouple cables

- Connection cables for PT sensors

- Multi-conductor wires (temp. -60C to +1400C)

- Medium voltage cables

- Ignition wires

- Heating cables

- Single conductor cables (temp. -60C to +450C)

- Railway cables

- Heating cables Ex

- Cables for the defense industry

- Go to the subcategory

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Full SiC MOSFETs 3.3 kV – Towards High-Performance Traction Inverters

3.3 kV Full SiC MOSFETs – Towards High-Performance Traction Inverters

Mitsubishi Electric is developing a new Full SiC device rated for 3.3 kV and 750 A. The device comes in the most recent LV100 package, which is especially suitable for traction application and modular converter designs. This article introduces the new Full SiC device and demonstrates the benefits in traction applications.

By Dr. Nils Soltau, Eugen Wiesner, Mitsubishi Electric Europe B.V., Ratingen, Germany and Kenji Hatori, Hitoshi Uemura, Mitsubishi Electric Corporation, Fukuoka, Japan

1. Introduction

Power semiconductor devices made of silicon carbide (SiC) are regarded as the major innovation in modern power electronics. Compared to classical silicon (Si) devices, SiC enables more efficient and more compact converters to save electric energy and valuable materials.

Over the last 20 years, Mitsubishi Electric has developed and commercialized SiC devices for several voltage classes and various applications [1]. Now, after years of in-field experience with different SiC modules in traction application [2], Mitsubishi Electric makes the next big step. With a rated voltage of 3.3 kV and a current of 750 A, the new Full SiC dual module is especially intended for high performance traction converters and flexible converter designs. The type name of this new device is FMF750DC-66A.

Due to the fast switching transients, Full SiC devices require an appropriate package offering low stray inductance. Therefore, the FMF750DC-66A, as shown in Figure 1, comes in the most advanced package for this voltage and power class: the LV100 package. This package offers a stray inductance below 10 nH and simpler parallel connection of several modules. Moreover, the internal package design ensures optimal current sharing among the semiconductor chips inside a module.

Figure 1: The new 3.3 kV Full SiC device is rated for 750 A and comes in the most recent LV100 package

2. Comparison with Silicon Devices

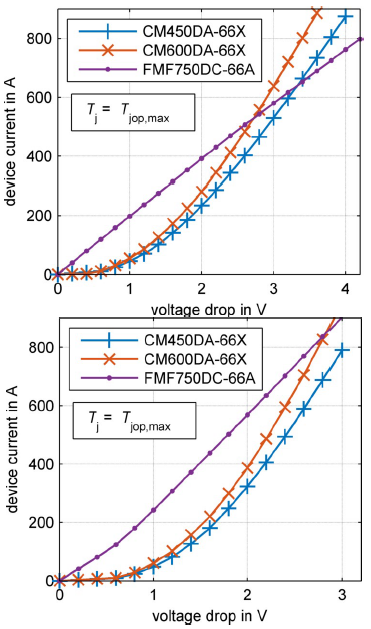

The following chapter compares the FMF750DC-66A with two different Si devices that also come in the same LV100 package. These two devices of the same voltage class are rated for 450 A and 600 A. In the following, they are referred to as CM450DA-66X and CM600DA-66X according to their respective type name. Figure 2 shows the static characteristics of all modules and, hence, demonstrates nicely the general difference between bipolar IGBTs and unipolar MOSFETs.

Figure 2: Static characteristic of the Full SiC devices compared to the 450 A and 600 A silicon-based modules

It should be noted that all device characteristics are given for the respective maximal junction temperature being 150°C for the Si devices and 175°C for the FMF750DC-66A. Due to the linear currentvoltage dependency of MOSFETs, the voltage drop at low currents is substantially lower than for bipolar IGBTs (cf. Figure 2 (a)). As shown in Figure 2 (b), also the voltage drop of the FMF750DC-66A in reverse direction is much smaller compared to the freewheeling diodes of the Si modules, if both, diode (SBD) and MOSFET, are conducting the reverse current (synchronous rectifier mode). Consequently, especially at low-load conditions, the use of unipolar devices increases converter efficiency significantly. The subsequent chapter quantifies this for a traction application.

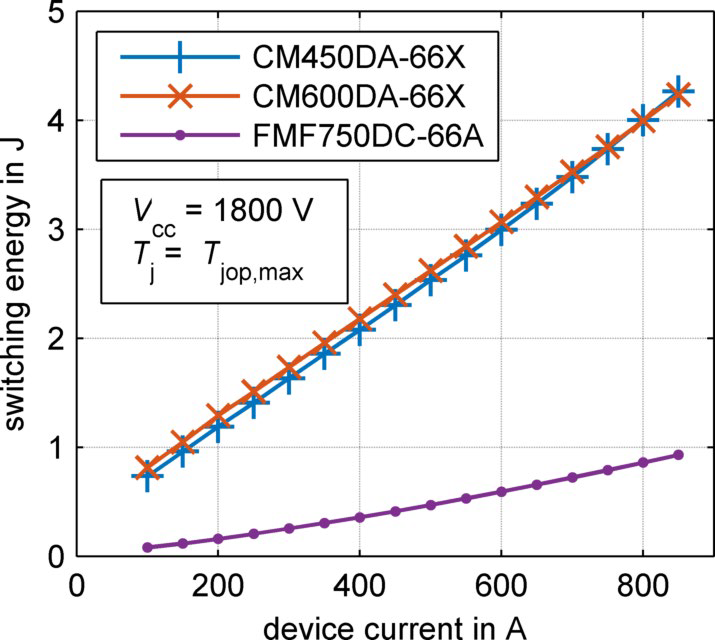

Figure 3: Switching losses of the Full SiC module compared to Sibased modules

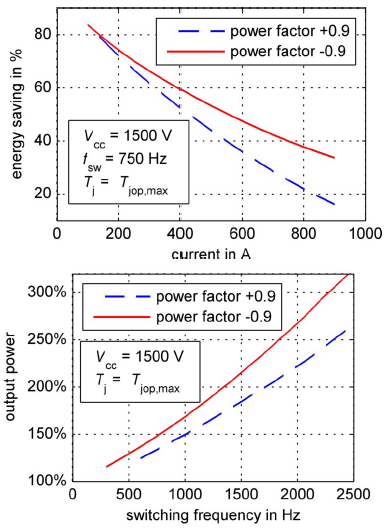

Figure 4: Comparison of FMF750DC-66A with CM600DA-66X

Another very prominent advantage of Full SiC devices is the reduction of switching losses. Again, this effect results from the unipolar nature of the devices. The lack of reverse recovery and tail currents decreases switching energy and allows higher switching frequencies compared to Si devices. Figure 3 shows the sum of energy loss during turn-on, turn-off and reverse recovery. Compared to the Si-based IGBTs, the switching losses in the Full SiC module are reduced by 80– 90 %.

The following chapter quantifies and discusses advantages for the converter design and intended applications.

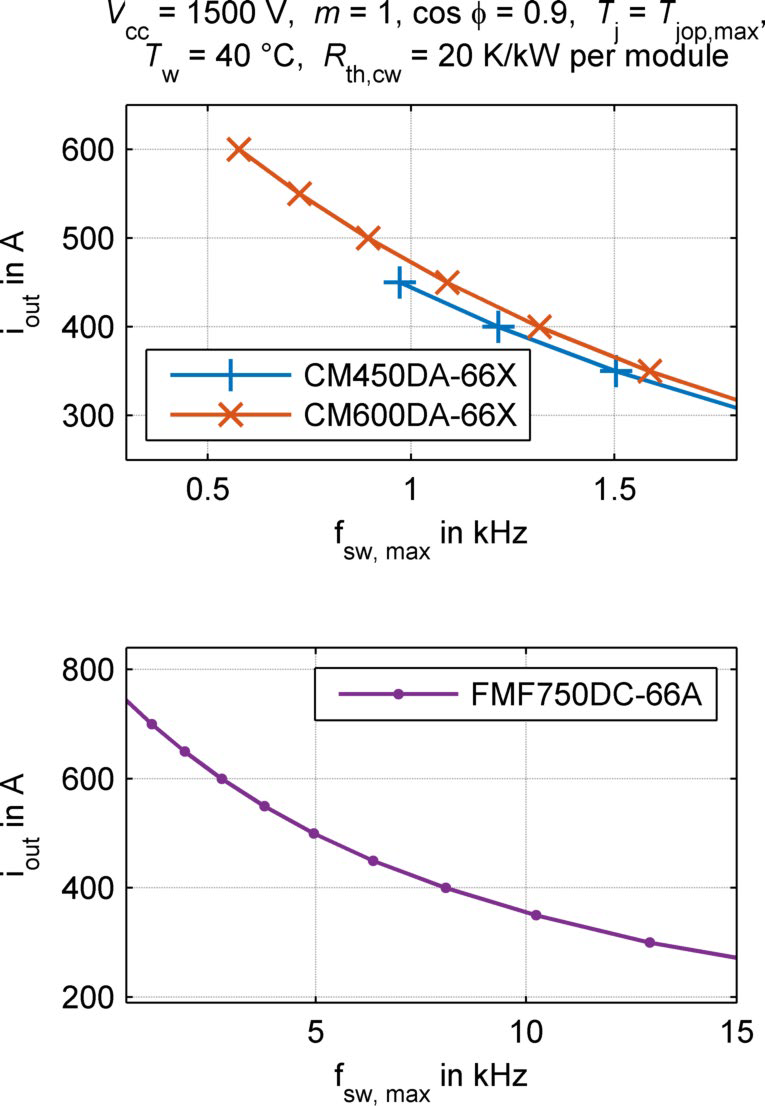

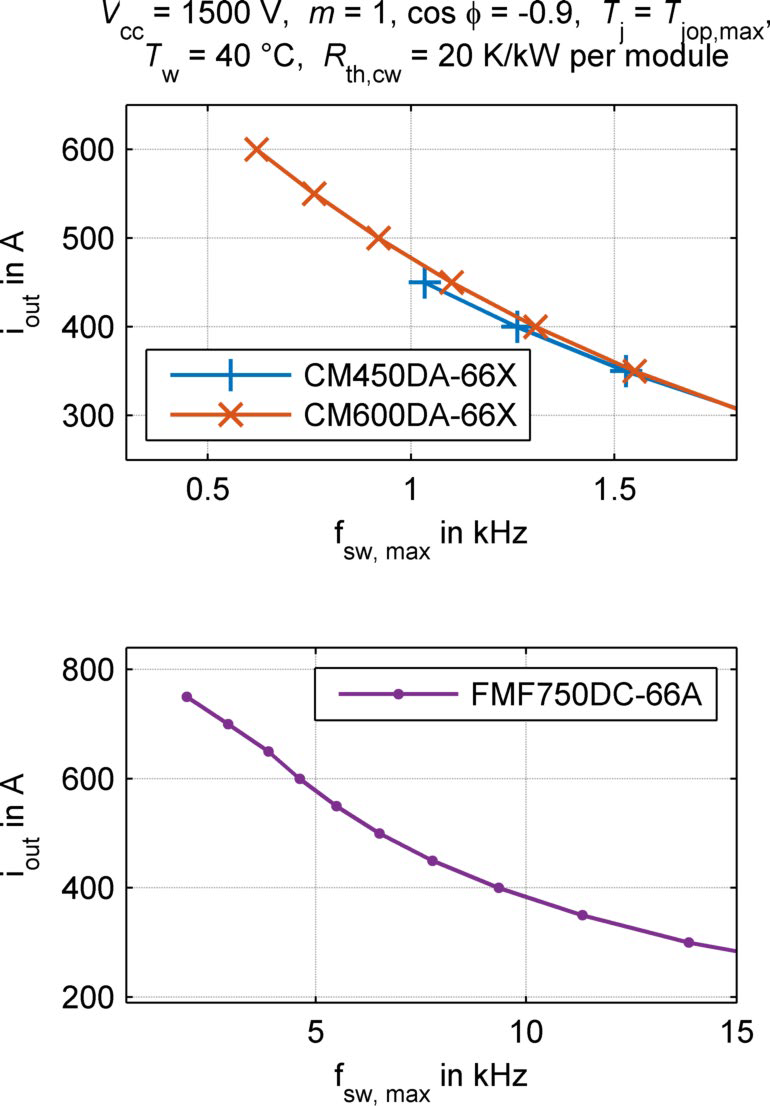

Figure 5: Maximal output current in dependence on switching frequency

3. System Level Advantages

The first example regards traction inverters with 750 Hz switching frequency at 1500 V dc-link voltage. The losses generated by the Si-based CM600DA-66X and the SiC-based FMF750DC-66A are compared. Figure 4 (a) shows the energy savings using the FMF750DC-66A instead of a CM600DA-66X. Especially at vehicle’s part-load condition, saving potential is enormous. Below 400 A output current, the Full SiC devices saves more than 50 % - 80 % of the energy loss by semiconductors (at the same device footprint).

Especially at part load, operational energy costs can be reduced. Moreover, due to higher efficiency and the higher operational junction temperature of the FMF750DC-66A, the maximal power in rectifier operation increases. As illustrated in Figure 4 (b), maximal output power increases by roughly 60 % at exemplary switching frequency of 750 Hz. Since the rectifier mode serves the recovery of energy when the vehicle slows down, potentially more energy can be recycled and fed back into the electricity network. Moreover, this reduces stress on the conventional braking system.

The second example considers a grid-connected converter operating at a power factor of 0.9. The maximal switching frequency in dependence on the output current is calculated. Figure 5 shows the results considering cooling water temperature of 40°C. Consequently, the maximal switching frequency for the FMF750DC-66A increases by a factor of 5 to 9 compared to the CM600DA-66X at same current level.

The higher switching frequency allows converter manufacturers a grid-filter design for higher resonance frequencies. Consequently, the required inductance and capacitance values for an LCL filter decrease. This in turn decreases filter’s size, cost and losses. Moreover, the converter achieves a more dynamic control. Furthermore, for machineside inverters or dc-dc converters, the higher switching frequency enables the design of more compact high-speed drives and medium-frequency converters [3,4].

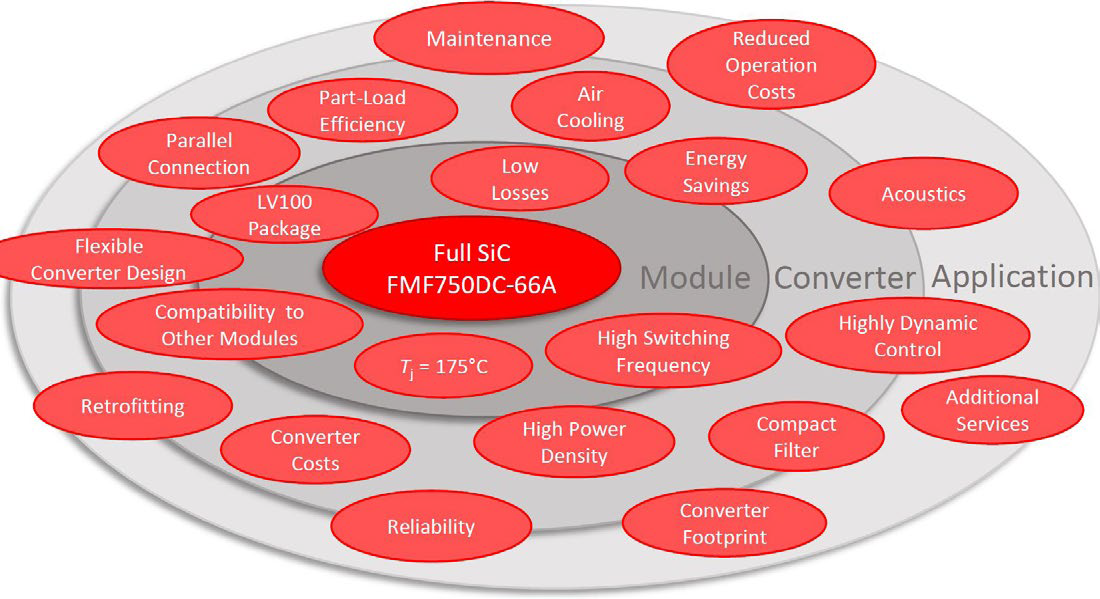

Figure 6: Opportunities enabled by the Full SiC FMF750DC-66A

Besides the switching frequency increase, Figure 4 (b) has already demonstrated that keeping the switching frequency constant, the converter achieves significantly higher output power. The fact that the FMF750DC- 66A comes in the same package as the CM450DA-66X and CM600DA-66X allows more flexible converter designs and fast development (having a similar inverter configuration as Si-based inverter).

Beyond the discussed benefits in traction and grid applications, the FMF750DC-66A make further benefits accessible. Figure 6 tries to illustrate the advantages of the FMF750DC-66A at different system levels: at module level, at converter level and at application level. In general the use of new FMF750DC-66A makes sense in those applications where these system-level advantages potentially over-compensate the higher costs of today’s SiC-modules compared to established silicon devices.

4. Conclusion

Mitsubishi Electric offers an extensive line up in the state-of-the-art LV100 package. Now, a 750 A Full SiC module is added to the 3.3 kV line up. The FMF750DC-66A Full SiC module increases the converter’s power density by increased switching frequency and higher maximal junction temperature of 175 °C. Moreover, the module achieves higher system efficiency. Especially at part load conditions or rectifier operation, the FMF750DC- 66A reduces the inverter losses by 50 – 80 %. The FMF750DC-66A comes in the same low-inductive LV100 package as its Si counterparts. For converter manufacturers, this simplifies the transition from Si to SiC and gives tremendous flexibility.

References

[1] E. Thal and J. Yamada, “SiC Power Modules for a Wide Application Range,” Bodo’s Power Systems, Sep 2017.

[2] Mitsubishi Electric, Mitsubishi Electric Installs Railcar Traction System with All- SiC Power Modules on Shinkansen Bullet Trains, Press Release No. 2942, June 2015.

[3] L. Luise and others, Design Optimization and Testing of High-Performance Motors: Evaluating a Compromise Between Quality Design Development and Production Costs of a Halbach-Array PM Slotless Motor, IEEE Industry Applications Magazine, 2016.

[4] M. Claessen, D. Dujic, F. Canales, J. K. Steinke, P. Stefanutti and C. Vetterli, Traction transfomration - A power-electronic traction transformer, ABB review, 01/2012.

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Leave a comment