-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

-

Recorders

- Hybrid Recorders - AL3000 Series | CHINO

- Graphic Recorder - KR2000 Series | CHINO

- Ubiquitous Recorders - KR5000 Series | CHINO

- Palm-sized Temperature/Humidity Meters - HN-CH Series | CHINO

- Consumables for Recorders

- 71VR1 - Compact Paperless Recorder | M-SYSTEM

- Graphic Recorder - KR3000 Series | CHINO

- PC Recorders - R1M Series | M-SYSTEM

- PC Recorders - R2M Series | M-SYSTEM

- PC Recorders - RZMS Series | M-SYSTEM

- PC Recorders - RZUS Series | M-SYSTEM

- Go to the subcategory

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- Galvanized and Stainless Steel Cylindrical Braids

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Hoses

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

New Transfer Molded SMD Type IPM

New Transfer Molded SMD Type IPM

Mitsubishi Electric has added a new transfer molded SMD type Intelligent Power Module to its line-up – the MISOP™. The MISOP™ is an ideal solution for high performance inverters in the range of 100W which require a high degree of compactness, high efficiency and easy assembly.

By Narender Lakshmanan and Muzaffer Albayrak from Mitsubishi Electric Europe B.V, Germany Teruaki Nagahara, Mitsubishi Electric Power Device Works, Japan

Introduction

Applications such as small drives (in the range of 100W output power) have certain special requirements with regards to the design of the power supply unit. The power supply unit encompasses the power semiconductor module and the associated peripheries (such as gatedrive, control, protection and heatsink) which are assembled using a single PCB. This unit must be able to deliver the highest possible efficiency and must offer a high degree of compactness. Additionally, it is expected that the modules must be mounted with minimum effort on the PCB. Considering the special requirements presented by such applications, the MISOP™ (Mitsubishi Electric Intelligent Small Outline Power Module) are being developed in the 1A/600V range and the 3A/600V range. The MISOP™ is SMD type Intelligent Power Module (IPM) which consists of integrated gate-driver components and bootstrap diodes.

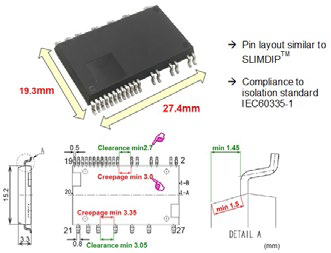

Figure 1 : Package dimensions of the MISOP™ and the pin layout indicating the compliance to the IEC60335-1

This product is a new addition in the Mitsubishi DIPIPM™ family of products which consist of transfer molded power semiconductors optimized for applications requiring a high degree of compactness and high operational efficiency.

Highly Optimized SMD type Power module:

The MISOP™ is based on the Mitsubishi 7th generation Reverse Conduction (RC) IGBT chip technology. The 7th generation chip technology is a low loss thin wafer IGBT technology which allows an optimization of the balance between performance and IGBT chip size. In addition to the inherent benefits of the 7th generation chip technology, the RC technology enables a significant level of optimization of the power module’s surface area requirement since the IGBT and the diode are effectively integrated into a single die. As a result, the chip surface which is normally used for the placement of diode dies are not required in this approach and therefore the IGBTs and the diodes necessary for a 3 phase inverter are effectively packed into a single package corresponding to the SOP footprint. Figure 1 indicates the size of the package and Figure 2 indicates the internal circuit topology of the power module. The pin assignment is similar to that of Mitsubishi’s SLIMDIP™ module from the DIPIPM™ series and the isolation standard has been designed under the consideration of market requirements of creepage and clearance distances.

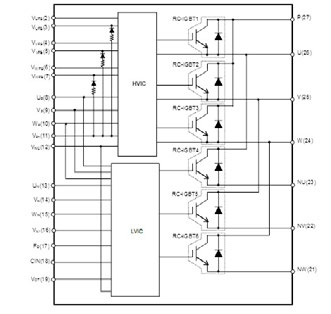

Figure 2 : The internal topology of the MISOP™

Pin design is also in accordance with the norm IEC60335-1. This product has been developed in the SMD package. It does not have throughhole pins and it can be soldered to the PCB using the reflow soldering technique which is intended to optimize efforts required in the assembly process. Continuing with the concept of the DIPIPMTM series, the MISOP™ is also equipped with integrated gate drive components. The module is equipped with embedded driver ICs: a Low Voltage IC (LVIC) which is responsible for driving the low side switches and a High Voltage IC (HVIC) which utilizes the bootstrap topology to drive the high side switches (with bootstrap diodes and current limiting resistors). The full integration of driver and protection functionality are guaranteed under Mitsubishi quality standards and allows to reduce the failure rate of whole inverter. Also, through the full integration, the number of peripheral components will be optimized and this would help the stock management. The embedded gate drive ICs also support several important protection functionalities. Figure 3 indicates the wiring pattern which has to be established in an application utilizing the MISOP™. The approach adopted by the MISOP™ avoids the needs for several undesirable cross points in the PCB tracks and even enables to use a single-side board. As a result, the PCB board design required for utilizing the MISOP™ is significantly simplified.

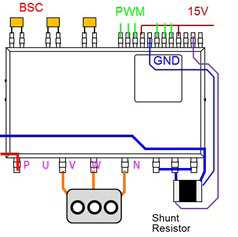

Figure 3: An example of the application circuit required for MISOP™ indicating the connections to the shunt resistors, Bootstrap-Capacitors, control input, control power supply and power terminals.

Performance Analysis

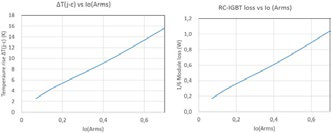

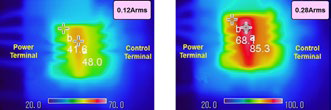

The increasing global awareness for carbon footprint reduction combined with the commercial benefit of reducing power consumption in appliances has motivated manufacturers of inverters (for applications such as small fans or pumps) in the range of 100W output power to adopt power semiconductors which deliver the highest possible efficiency during operation. Therefore, along with the advantage of offering compactness and easy design, the MISOP™ must be able to perform well under the required operating conditions. Figure 4 indicates simulation results of the power loss performance with the 1A device MISOP™ for different RMS inverter current Iout(rms) and the corresponding increase in the ΔTj-c(average) for the given values of the Iout(rms). Considering an inverter with the following nominal working conditions: Iout = 0.283 Arms, Vcc = 300V, fc = 20 kHz, pf = 0.8, modulation index = 1; the 3 phase output power is approximately 72W by using the 1A devices (SP1SK) from MISOP™ family. Using the data from Figure 4, we understand that the total power loss is around 2.76W. This performance indicates a power module efficiency of around 96%. Although the MISOP™ is highly compact in volume, it can be observed that this module is capable of delivering excellent thermal performance. With regards to the thermal performance, it is evident that the ΔTj-c(average) for this operating point is around 7 K for each RC-IGBT. Under these operating conditions, (considered an air cooled heatsink with effective Rthc-s =16 K/W for the entire module and ambient temperature of around 40°C) the temperature of the case remains at around 85°C and the average junction temperature remains at around 92°C. Figure 5 indicates the thermal performance of the module captured via a thermal camera (this analysis was performed without any external heatsink). A combination of high operational efficiency and good thermal performance enables the inverter to achieve maximum output power from this MISOP module.

Figure 4: Tentative data pertaining to the thermal and electrical loss performance of a single RC-IGBT device (MISOP™). Conditions: Vcc = 300V, fc = 20 kHz, pf = 0.8, M = 1, Three Phase Modulation, Rth(j-c) maximum, Tj = 125°C, heatsink connected.

Integrated Protection Functions

Along with the requirement for high efficiency, it also necessary to ensure that the inverter is designed using a high performance power module with regards to protection against irregular operation modes. The MISOP™ is provided with several integrated protection functions (please refer to Table 1). The device offers the possibility to implement a short circuit protection via external shunt resistances which can be connected to each of the open emitter pins. To avoid the risk of overheating during operation, there is a built-in overtemperature protection function (OT) and there is a possibility of monitoring the module temperature with an accurate linear analog voltage output signals (VOT), which could help to define the derating points to use the module with high power density. The availability of the “interlock-protection” is an important implementation, this protection function prevents the simultaneous turn-on of both high side and low side switches (such a turn-on would lead to an arm-shot through short circuit). In addition, there is a system to detect and indicate a failure in the control supply voltage. An unstable input to the control power supply can lead to undefined switching states and subsequently thermal run-away of power chips. A failure event in any of the low side switches would be indicated via the Fo signal (except for interlock function).

| # | Functions available in the MISOP™ |

|---|---|

| 1 | Under voltage protection (UV) |

| 2 | Short circuit Protection (SC) |

| 3 | Over temperature protection (OT) |

| 4 | Temperature information output (VOT) |

| 5 | Arm short circuit protection -> Interlock (IL) |

| 6 | Failure output (Fo) |

| 7 | Bootstrap diode (BSD) |

| 8 | Open emitter N side :Three shunts can be connected |

Table 1 : List of internal functionalities available in the MISOP™

Summary

Indices such as the APF (Annual Performance Factor) pertaining to efficiency have gained significance in recent years and have motivated the manufacturers of appliances such as small fans, pumps and various other such appliances which require an output power in the range of 100W to consider power semiconductor devices which offer high operational efficiencies. Simultaneously, the demand for inverter size optimization has led to the demand for highly optimized power modules. On the other hand, such a compact power module must also be robust and offer high reliability. The MISOP™ is designed to address the requirements of this sector. In addition to the availability of integrated functionalities (such as protection functions), the MISOP™ package allows for easy and efficient assembly process. In addition, it must also be noted that the wiring scheme required for the MISOP™ facilitates an easy PCB design thanks to similar pin layout with Mitsubishi’s SLIMDIP™ module and the secured pin to pin isolation distance in accordance with isolation standard IEC60335-1.

Figure 5: Heatsink-less operation captured using a thermal camera Vcc=270V, VD=15V, Io=0.12 and 0.28Arms, fc=16kHz, Modulation= 1, Three phase sine wave, Natural convection (no forced air), Ta=20.9~21.6ºC, Evaluation board, typical data.

References

[1] The DIPIPM™ family concept http://www.mitsubishielectric.com/semiconductors/products/powermod/dipipm/index.html

[2] Datasheet – SLIMDIP Module: http://www.mitsubishielectric.com/semiconductors/content/product/powermodule/dipipm/slimdip/slimdip-s_e.pdf

[3] Press release: Mitsubishi Electric to Launch MISOP Surfacemount Package IPM http://de.mitsubishielectric.com/de/newsevents/releases/global/2018/0416-a/index.page

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Leave a comment