-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

-

Recorders

- Hybrid Recorders - AL3000 Series | CHINO

- Graphic Recorder - KR2000 Series | CHINO

- Ubiquitous Recorders - KR5000 Series | CHINO

- Palm-sized Temperature/Humidity Meters - HN-CH Series | CHINO

- Consumables for Recorders

- 71VR1 - Compact Paperless Recorder | M-SYSTEM

- Graphic Recorder - KR3000 Series | CHINO

- PC Recorders - R1M Series | M-SYSTEM

- PC Recorders - R2M Series | M-SYSTEM

- PC Recorders - RZMS Series | M-SYSTEM

- PC Recorders - RZUS Series | M-SYSTEM

- Go to the subcategory

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- Galvanized and Stainless Steel Cylindrical Braids

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Hoses

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Power Supply Optimization: Challenges, Technologies, and Solutions

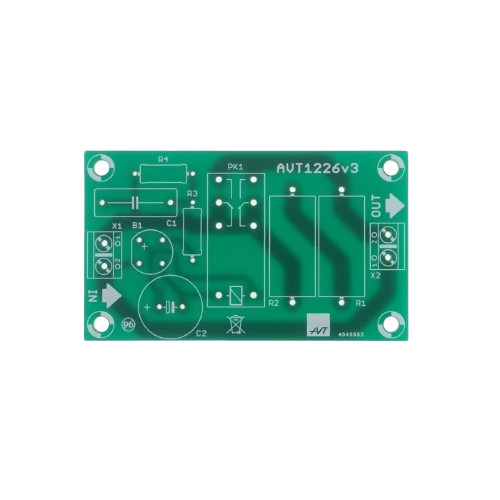

Contemporary power supply systems on PCBs (Printed Circuit Board) are a crucial element in the development of new electronic devices. Requirements related to miniaturization, energy efficiency, and operational stability pose significant challenges for designers. Products such as power supplies, converters, and voltage regulation systems must meet increasingly stringent standards regarding energy, space, and performance[1].

Challenges in Power Supply Design

The challenges related to power supply design encompass technical, economic, and environmental aspects. Notable difficulties include:

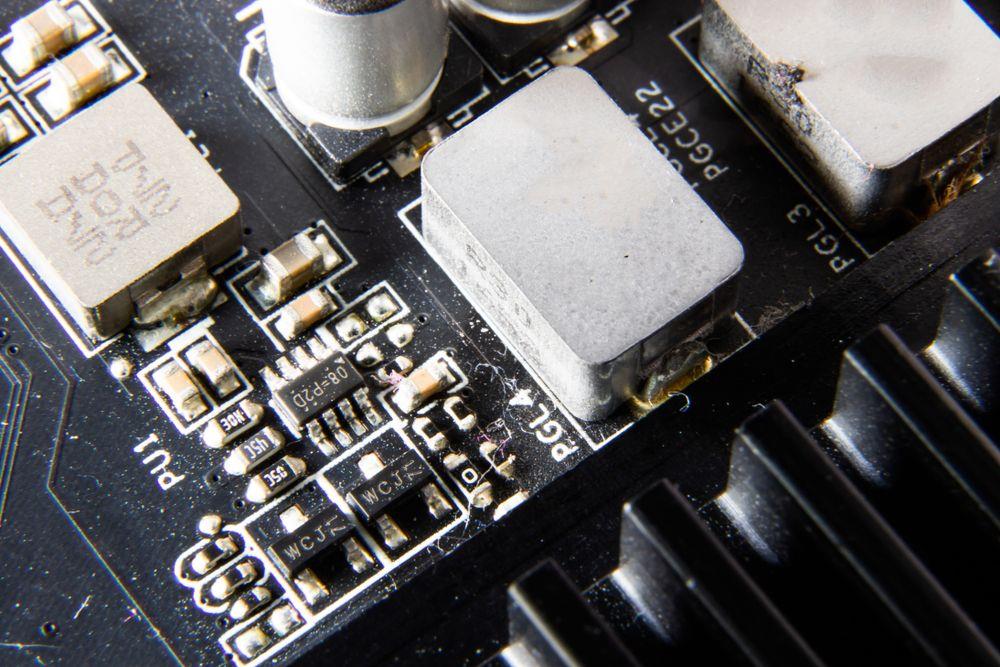

- Miniaturization of components - Devices are becoming smaller, requiring power supply designs with high efficiency in limited space[2].

- Heat management - Improper design can lead to overheating of the system, resulting in failure. The use of heat sinks and fans is crucial for the stability of systems[1].

- Increased energy requirements - Modern technologies require the supply of proper voltage with minimal energy losses[2].

Technologies Used in Power Supply Systems

R&D engineers utilize various technologies to address design challenges:

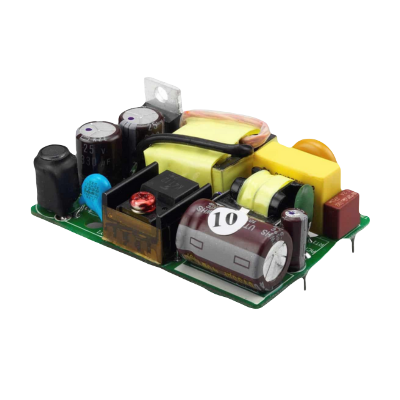

- DC-DC converters: Enable voltage adjustment to meet component requirements. Buck and boost technologies allow for lowering or increasing the voltage, while buck-boost models offer flexibility with various input voltages[3].

- AC-DC converters: Provide conversion of energy from alternating current to direct current, which is essential for applications powered by the electrical grid[4].

- Voltage regulators: Crucial for ensuring proper power quality for sensitive components[1].

Miniaturization and Space Optimization

In the context of miniaturization, new techniques for space optimization on PCBs are emerging:

- System on a Chip (SoC): Allows for reduced PCB size and improved energy efficiency[2].

- Increased operating frequency: Enables reduction in the size of passive components such as capacitors and transformers[3].

- New materials: The use of graphene and advanced magnetic materials contributes to improved energy efficiency and heat management[4].

Prototyping and Diagnostics

Prototypes in R&D require flexible and reliable power systems. Typical challenges include:

- Voltage flexibility: Modular voltage converters allow for quick adaptation of parameters to changing project needs[1].

- Diagnostics: Oscilloscopes and electronic load simulators are used to analyze system performance and identify anomalies[2].

Aerospace, Medical, and Military Industries

In projects related to the aerospace, medical, and military industries, the reliability of power supply systems is critical. In these cases, solutions that minimize the risk of failure are applied, such as power redundancy and advanced cooling technologies[4].

The Future of Power Supply Systems

Looking to the future, R&D engineers must stay updated with new technologies and materials. Power supplies based on Gallium Nitride (GaN) offer significantly higher energy efficiency than traditional silicon components, allowing for the development of smaller converters. Dynamic energy management and miniaturization through multilayer technology (LTCC) are other development trends in the industry[3][4].

All these aspects highlight the importance of solutions in power supply design and their impact on the development of modern electronic devices.

Bibliography:

[1] https://resources.altium.com/pl/p/guide-pcb-power-supply-layout

[2] https://evertiq.pl/design/19262

[3] https://www.tcl.com/pl/pl/blog/guides/what-is-pcb-the-advantages-of-using-it-in-ac

[4] https://forbot.pl/blog/katalog-firm/montaz-plytek-drukowanych-pcb-co-warto-wiedziec

[5] https://propcb.pl/technologie/

[6] https://elektronikab2b.pl/technika/54036-projektowanie-pcb-dla-ukladow-duzej-mocy

[7] https://hilelectronic.com/pl/design-power-pcb/

[8] https://home.agh.edu.pl/~ggora/lectures/ProjektowaniePCB.pdf

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Folia samoprzylepna z wypełnieniem ceramicznym

Folia samoprzylepna z wypełnieniem ceramicznym

Heat management - Challenges for electric vehicles

Heat management - Challenges for electric vehicles

Leave a comment